Automobile roof prepared from non-woven cloth and sponge

A car roof and non-woven fabric technology, applied in the field of car interior accessories, can solve the problems of lack of heat insulation and flame retardancy, poor air permeability, lack of shock absorption and buffering performance, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

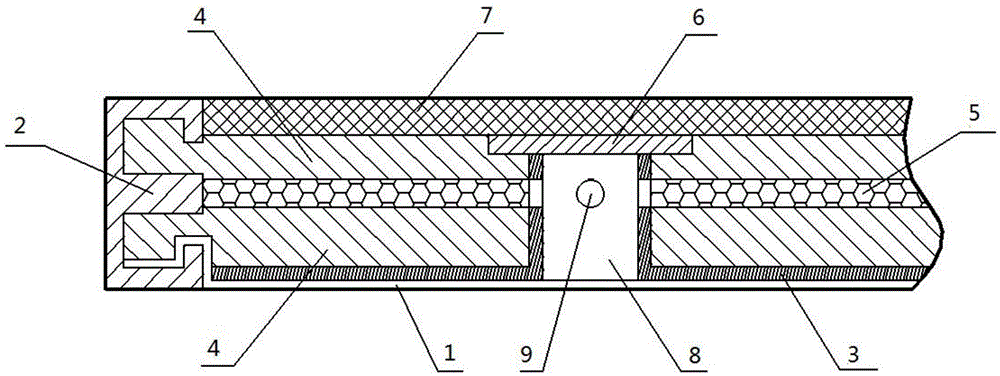

[0015] The specific embodiments of the present invention are given below with reference to the accompanying drawings, which are used to further describe the composition of the present invention in detail.

[0016] A car roof made of non-woven fabric and sponge in this embodiment is to include a car roof inner layer 1, a flame-retardant and heat-insulating layer 3 is installed above the car roof inner layer 1, and a large fire-retardant and heat-insulating layer 3 is arranged inside the car roof Ventilation hole 8, shock-absorbing rubber plate 6 is installed above the large vent hole 8, small vent hole 9 is arranged in the large vent hole 8, the small vent hole 9 communicates with the fiber layer 5, and a sponge layer is installed above the flame-retardant heat insulation layer 3 4. The fiber layer 5 is installed in the middle of the sponge layer 4, the inner layer 1 of the car roof and the sponge layer 4 are embedded in the sealing strip 2, and the roof cover 7 is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com