Method for preparing foam microcrystalline glass through red mud

A foamed glass-ceramic and red mud technology, applied in the field of foamed glass-ceramic, can solve the problems of harming the environment and destroying cultivated land, and achieve the effects of low cost, promoting crystallization, and rich sources of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

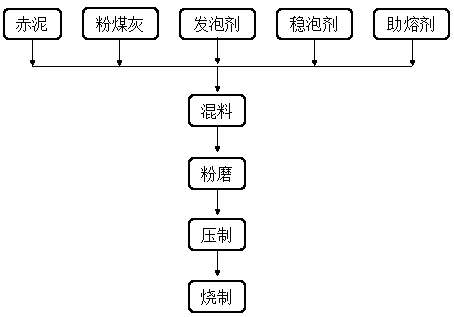

Image

Examples

Embodiment 1

[0035] A method for producing foamed glass-ceramics from red mud and the prepared foamed glass-ceramics, the ingredients are as follows:

[0036] In parts by weight, the composition and dosage of the foamed glass-ceramic batch (100 parts in total, the same below) are: red mud 10, fly ash 45, calcium carbonate 3, dolomite 3, trisodium phosphate 7. Borax 32. The experimental steps are:

[0037] 1) Mixing: According to the ratio of raw materials, weigh red mud, fly ash, calcium carbonate, dolomite, trisodium phosphate, borax, mix evenly, and the mixing time is 5-10 minutes;

[0038] 2) Grinding: put the uniformly mixed batch into a ball mill and grind for 2.5 hours;

[0039] 3) Compression: Put the ground batch material into the abrasive tool and press it into a cylindrical sample with a radius of 25mm and a thickness of 7mm;

[0040] 4) Firing: Put the pressed sample into a reaction furnace and keep it warm at 900°C for 30 minutes to prepare foamed glass-ceramics.

Embodiment 2

[0042] A method for producing foamed glass-ceramics from red mud and the prepared foamed glass-ceramics, the ingredients are as follows:

[0043] In parts by weight, the composition and dosage of the foamed glass-ceramic batch (100 parts in total, the same below) are: red mud 15, fly ash 45, calcium carbonate 3, dolomite 2, trisodium phosphate 3. Zinc oxide 2. Borax 30. The experimental steps are:

[0044] 1) Mixing: According to the ratio of raw materials, weigh red mud, fly ash, calcium carbonate, dolomite, trisodium phosphate, zinc oxide, borax, mix evenly, and the mixing time is 5 to 10 minutes;

[0045] 2) Grinding: put the uniformly mixed batch into a ball mill and grind for 2 hours;

[0046] 3) Compression: Put the ground batch material into the abrasive tool and press it into a cylindrical sample with a radius of 25mm and a thickness of 7mm;

[0047] 4) Firing: Put the pressed sample into a reaction furnace and keep it warm at 870°C for 25 minutes to prepare foamed ...

Embodiment 3

[0049] A method for producing foamed glass-ceramics from red mud and the prepared foamed glass-ceramics, the ingredients are as follows:

[0050] In parts by weight, the composition and dosage of the foamed glass-ceramic batch (100 parts in total, the same below) are: red mud 12, fly ash 45, sodium carbonate 3, carbon powder 2, zinc oxide 3 , Borax 35. The experimental steps are:

[0051] 1) Mixing: According to the ratio of raw materials, weigh red mud, fly ash, sodium carbonate, carbon powder, zinc oxide, borax, and mix evenly. The mixing time is 5 to 10 minutes;

[0052] 2) Grinding: put the uniformly mixed batch into a ball mill and grind for 3 hours;

[0053] 3) Compression: Put the ground batch material into the abrasive tool and press it into a cylindrical sample with a radius of 25mm and a thickness of 7mm;

[0054] 4) Firing: Put the pressed sample into a reaction furnace and keep it warm at 850°C for 20 minutes to prepare foamed glass-ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com