Thermal insulation system structure for mineral wool coated building

A thermal insulation and system construction technology, applied in building structure, building components, thermal insulation, etc., can solve problems such as shrinkage joint fittings of anti-cracking mortar, anti-cracking mortar formula of waterproofing agent, etc., and achieve earthquake resistance Excellent performance, improved thermal insulation, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in more detail below in conjunction with accompanying drawing example:

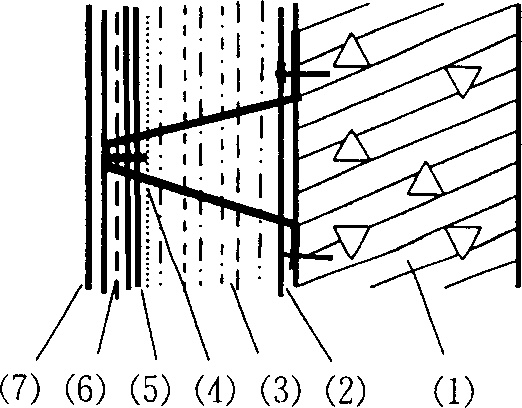

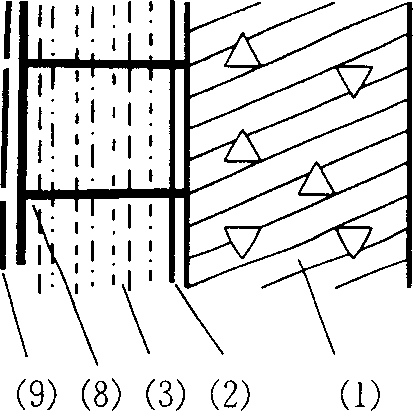

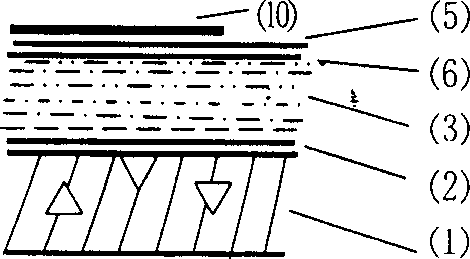

[0035] combine figure 1 , it is the first mineral wool sprayed building thermal insulation system structure, and it is a mineral wool sprayed building thermal insulation system structure with anchor bolts. The waterproofing agent is sprayed on the base 1 of the exterior wall of the building to form a moisture-proof layer 2. The moisture-proof layer has the functions of insulating moisture, increasing the bonding strength between the heat-insulating layer and the base, and protecting the heat-insulating layer. It is mixed with sodium methyl siliconate and water at a weight ratio of 1:10, and then added to portland cement to make a slurry for use. Mineral wool insulation layer 3 is sprayed outside the moisture-proof layer. The heat-insulation layer is a mixture of mineral wool and binder, which is sprayed on the surface of the moisture-proof layer of the building m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com