Light high-strength geopolymer material and preparation method thereof

A geopolymer and high-strength technology, applied in the field of geopolymer and its preparation, can solve the problems of uneven settlement of bridges, cracks, large shrinkage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing the above-mentioned lightweight and high-strength geopolymer material, comprising the following steps:

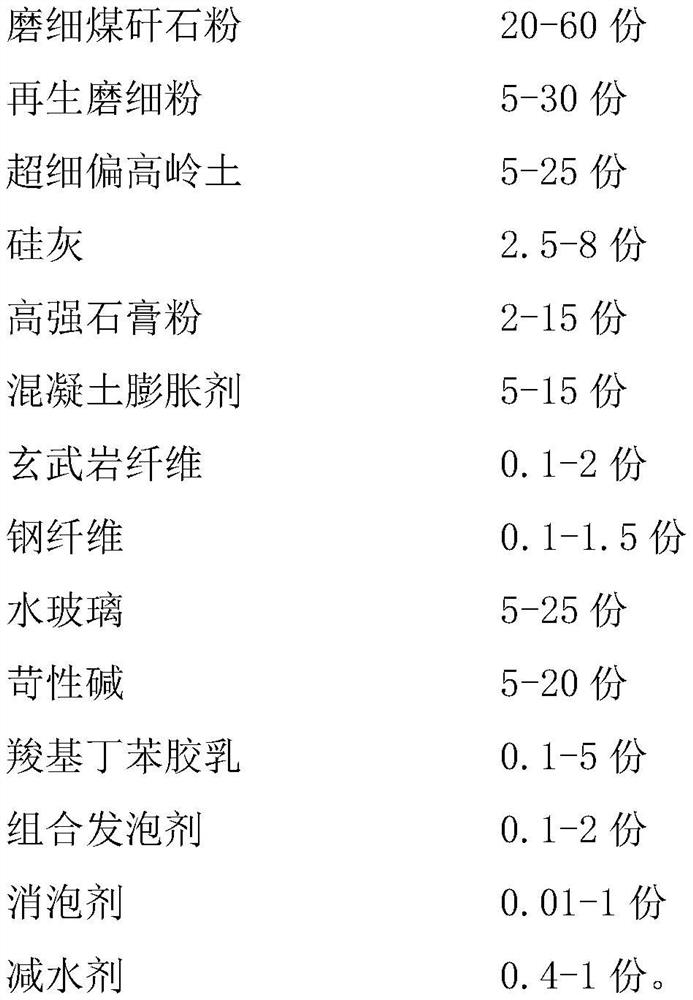

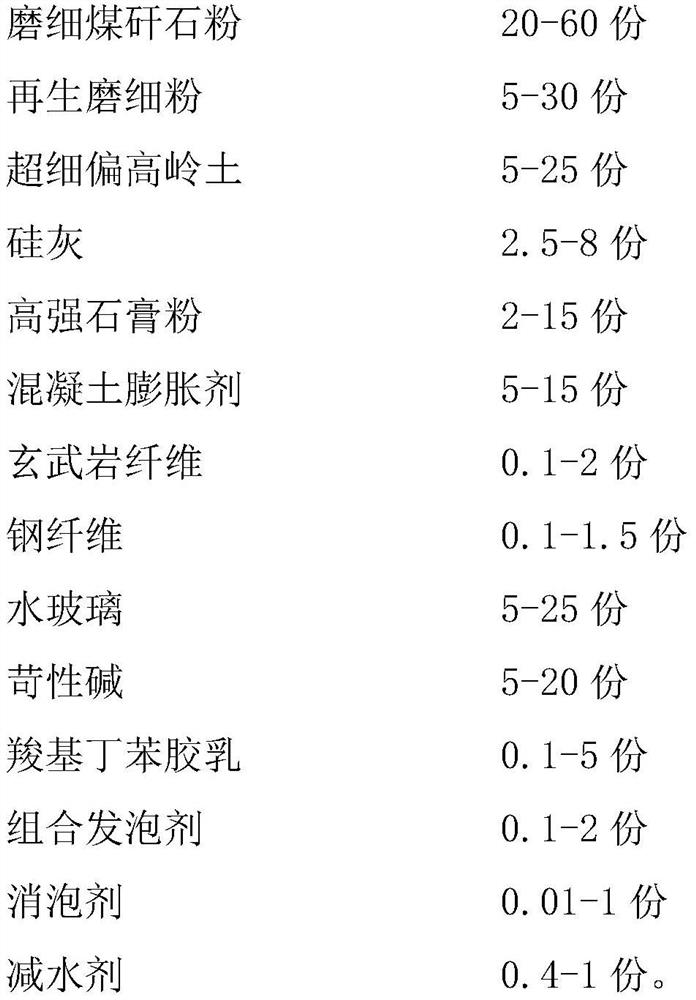

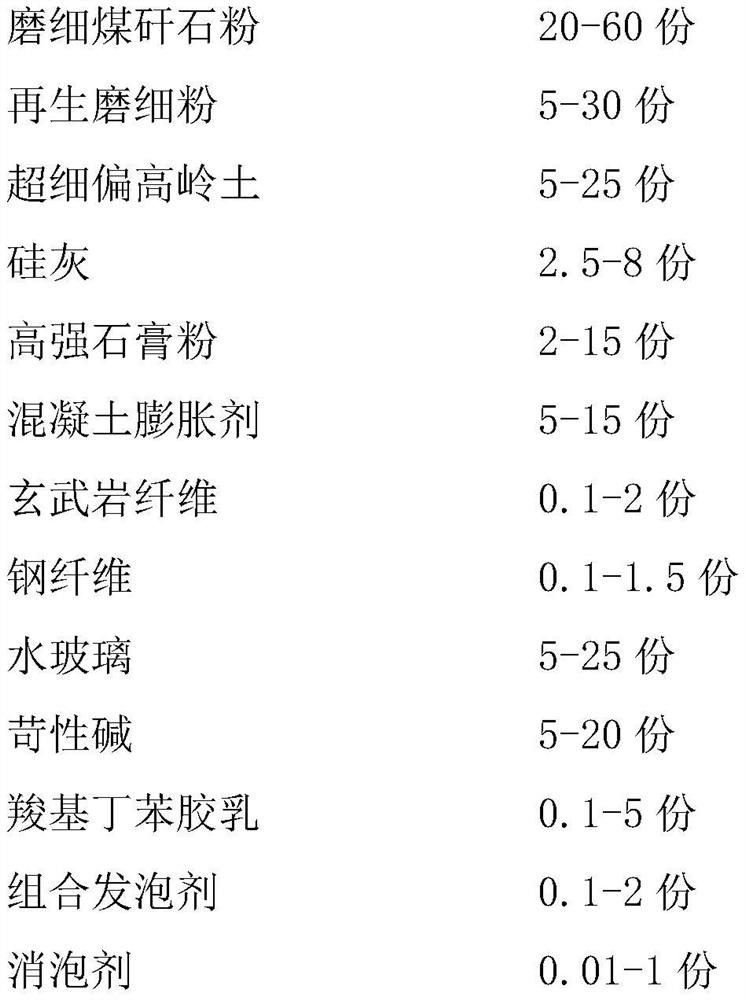

[0036](1) 20-60 parts of finely ground coal gangue powder, 5-30 parts of regenerated fine powder, 5-25 parts of superfine metakaolin, 2.5-8 parts of silica fume, 2-15 parts of high-strength gypsum powder, 5-15 parts 1 part of concrete expansion agent, 0.1-2 parts of basalt fiber, 0.1-1.5 part of steel fiber, 0.01-1 part of defoamer, 0.4-1 part of water reducing agent, put them into the mortar mixer, at the speed of 300-500r / min , and stirred for 3-5 minutes until uniform, to obtain a geopolymer dry mix.

[0037] (2) First weigh 1 / 4 of the total mixing water (water temperature is 20-30°C) and add it to a 500ml or 1000ml plastic beaker, then add 0.1-5 parts of carboxylated styrene-butadiene latex and 0.1-2 parts of combined foam Add the agent into the beaker, use a hand-held small mixer, at the speed of 5000-8...

Embodiment 1

[0043] This embodiment provides a light-weight and high-strength geopolymer material, which includes: 41.4 parts of ground coal gangue powder, 5 parts of regenerated ground powder, 20 parts of ultrafine metakaolin, 2.5 parts of silica fume, 5 parts by weight High-strength gypsum powder, 5 parts of concrete expansion agent, 0.2 part of basalt fiber, 0.1 part of steel fiber, 0.1 part of defoamer, 0.5 part of polycarboxylate superplasticizer, 0.1 part of carboxylated styrene-butadiene latex, 0.1 part of combined foaming agent, 15 Part sodium water glass and 5 parts sodium hydroxide etc.

[0044] The present embodiment provides a kind of lightweight high-strength geopolymer material, and its preparation method comprises the following steps:

[0045] (1) 41.4 parts of finely ground coal gangue powder, 5 parts of regenerated fine powder, 20 parts of superfine metakaolin, 2.5 parts of silica fume, 5 parts of high-strength gypsum powder, 5 parts of concrete expansion agent, 0.2 parts ...

Embodiment 2

[0051] This embodiment provides a light-weight and high-strength geopolymer material, which includes: 37.4 parts of ground coal gangue powder, 15 parts of regenerated fine powder, 10 parts of ultrafine metakaolin, 2.5 parts of silica fume, 5 parts by weight High-strength gypsum powder, 7 parts of concrete expansion agent, 0.3 part of basalt fiber, 0.2 part of steel fiber, 0.1 part of defoamer, 0.5 part of polycarboxylate superplasticizer, 1.2 parts of carboxylated styrene-butadiene latex, 0.8 part of combined foaming agent, 15 Part sodium water glass and 5 parts sodium hydroxide etc.

[0052] The present embodiment provides a kind of lightweight high-strength geopolymer material, and its preparation method comprises the following steps:

[0053] (1) 37.4 parts of finely ground coal gangue powder, 15 parts of regenerated fine powder, 10 parts of superfine metakaolin, 2.5 parts of silica fume, 5 parts of high-strength gypsum powder, 7 parts of concrete expansion agent, 0.3 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com