Vibration damper for automotive exhaust pipe

A vibration damping device and automobile exhaust technology, which is applied in the direction of exhaust devices, noise reduction devices, adhesive additives, etc., can solve the problems of large space occupation and complex structure, and achieve small space occupation, simple preparation process and good cushioning performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

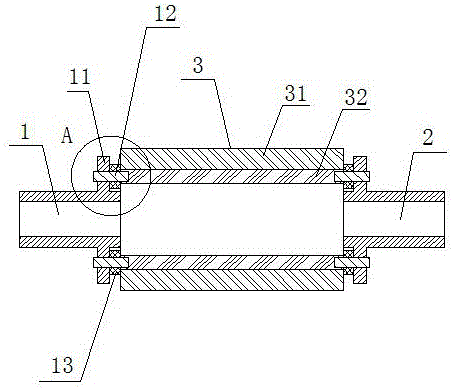

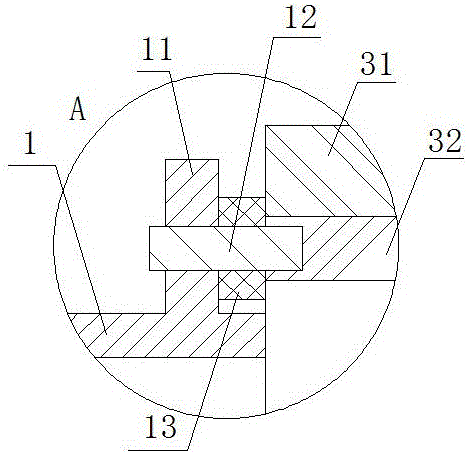

[0034] Such as Figure 1 to Figure 2 As shown, the present invention provides an automobile exhaust pipe vibration damping device, which includes an intake pipe 1, a vibration damping tube 3 communicating with the air intake pipe 1, and an air outlet pipe 2 communicating with the vibration damping tube 3. When the automobile exhaust pipe damping device of the present invention is in use, it can be installed between the exhaust pipe of the automobile and the engine or transmission. The intake pipe 1 is connected with the engine or transmission, and the outlet pipe 2 is connected with the automobile exhaust pipe. Attenuate engine vibration and improve driving comfort.

[0035] Specifically, the damping cylinder 3 includes a buffer cylinder 32 located inside and a rubber cylinder 31 located outside the buffer cylinder 32; both the intake pipe 1 and the outlet pipe 2 are provided with an annular connecting plate 11, and the annular connecting plate 11 is connected to each other by bo...

Embodiment 2

[0038] The cushioning material for automobile exhaust pipe vibration damping device, from top to bottom, includes the upper polyurethane foam layer, the upper acrylic resin layer, the PET substrate, the lower acrylic resin layer, and the lower polyurethane foam layer. The weight ratio of the 5 layers is 2:3:1:1:2, each layer is bonded by water-based polyurethane adhesive.

Embodiment 3

[0040] The preparation method of buffer material for automobile exhaust pipe damping device, the steps are as follows:

[0041] 1) Pretreatment of PET substrate

[0042] Use acetone to scrub the surface of the PET substrate to remove oil stains, then wipe the PET substrate with a dry cloth, then scrub with ether, and finally dry in a dust-free environment;

[0043] 2) Adhesion and post-treatment of upper and lower acrylic resin layers

[0044] Apply the water-based polyurethane adhesive to the upper and lower sides of the PET substrate, the amount of brushing is 300g / m 2 , Then the acrylic resin layer is compounded on the upper and lower sides of the PET substrate, the extrusion strength is 5Mpa, and the extrusion time is 2 minutes; after bonding, it is placed in a 50 ℃ environment for drying for 3 hours;

[0045] 3) Bonding and post-treatment of the upper and lower polyurethane foam layers

[0046] Apply the water-based polyurethane adhesive to the upper surface of the upper acrylic res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com