An optimization method of zero-crossing torque shock of motor for new energy vehicles

A technology of motor torque and new energy vehicles, which is applied in the field of vehicle impact resistance, can solve problems affecting driving comfort, etc., and achieve the effects of improving driving comfort, reducing vehicle impact, and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The method for optimizing the zero-crossing impact of the motor torque of the new energy vehicle of the present invention, through the following steps, reduces the tooth impact of the driving gear:

[0026] 1) Detect the zero-crossing torque of the motor:

[0027] The motor torque zero crossing includes the motor positive torque to negative torque zero crossing and negative torque to positive torque zero crossing, and the zero crossing detection algorithm is used to detect the zero crossing point of the torque;

[0028] 2) After the torque zero-crossing point is detected, the slope of the torque rise or fall is limited to change the original change track of the torque, thereby achieving the purpose of reducing the impact of the torque zero-crossing.

[0029] Such as figure 1 As shown, the root cause of the zero-crossing impact of the motor torque is that when the torque crosses zero, the driving gear changes from one side to the other side of the tooth, resulting in a ...

Embodiment 2

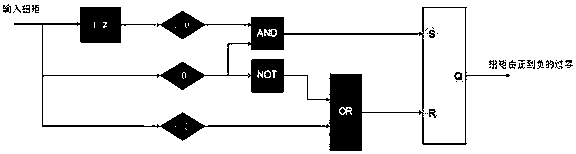

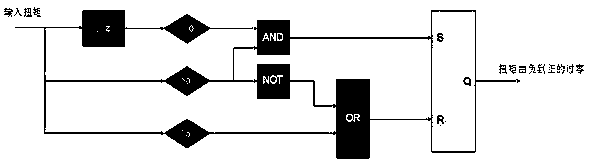

[0031] The optimization method of the torque zero-crossing impact of the new energy vehicle motor in this embodiment is different from Embodiment 1 in that it further discloses the zero-crossing torque of the motor from positive torque to negative torque and from negative torque to positive torque. The detection process is as follows:

[0032] see Figure 2a , the vehicle controller (VCU) detects the driving motor torque in real time. When it detects that the current torque is less than zero, and the torque at the previous moment is greater than or equal to zero, and the torque window is greater than -5, it is judged that the current motor torque has a zero-crossing from positive to negative;

[0033] see Figure 2b The vehicle controller (VCU) detects the torque of the driving motor in real time. When it detects that the current torque is greater than zero, and the torque at the previous moment is less than or equal to zero, and the torque window is less than 5, it is judged...

Embodiment 3

[0036] The optimization method of the new energy vehicle motor torque zero-crossing impact in this embodiment is different from Embodiment 1 or Embodiment 2 in that: the process of controlling the slope of the torque change is divided into three stages: no zero-crossing processing, and directly output the current torque ;

[0037] There are positive to negative zero crossings, the slope of the limit torque reduction, 0.2 ~ 0.3 NM per cycle;

[0038] There is a negative to positive zero crossing, limiting the slope of torque growth, 0.2 to 0.3 NM per cycle.

[0039] Figure 5 is a schematic diagram of torque optimization in the present invention; Figure 6 Torque Control Slope Optimization Curve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com