Preparation method of composite spinning skin-core structure polypropylene electrostatic staple fiber

A polypropylene, layer structure technology, applied in melt spinning, fiber treatment, conductive/antistatic filament manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with the examples, but it should be understood that these descriptions are only for further illustrating the features and advantages of the present invention rather than limiting the patent requirements of the present invention.

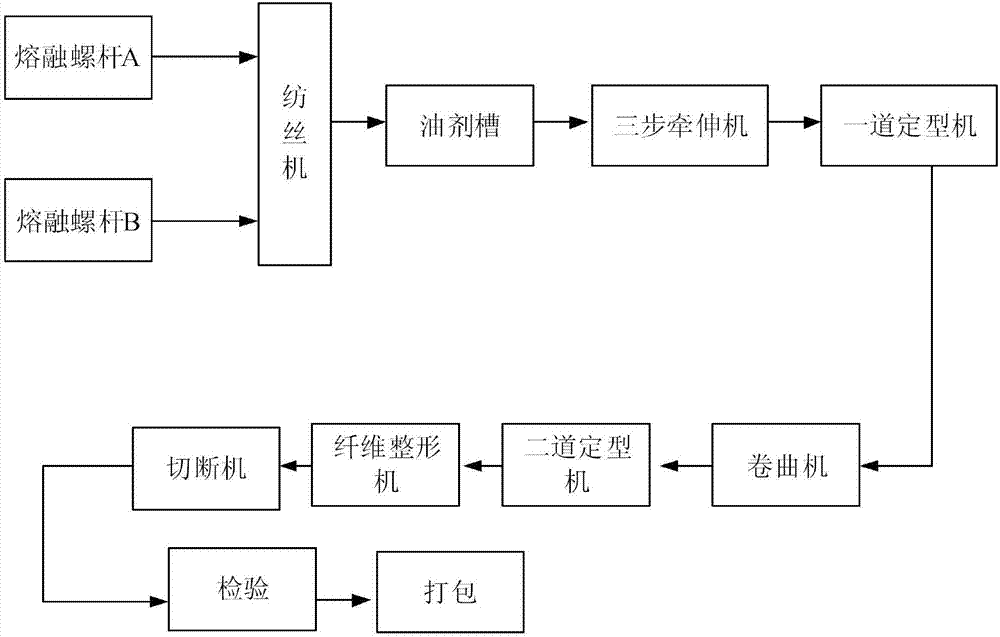

[0017] Please refer to figure 1 , a kind of preparation method of composite spinning sheath-core layer structure polypropylene electrostatic short fiber provided by the present invention, comprises as follows:

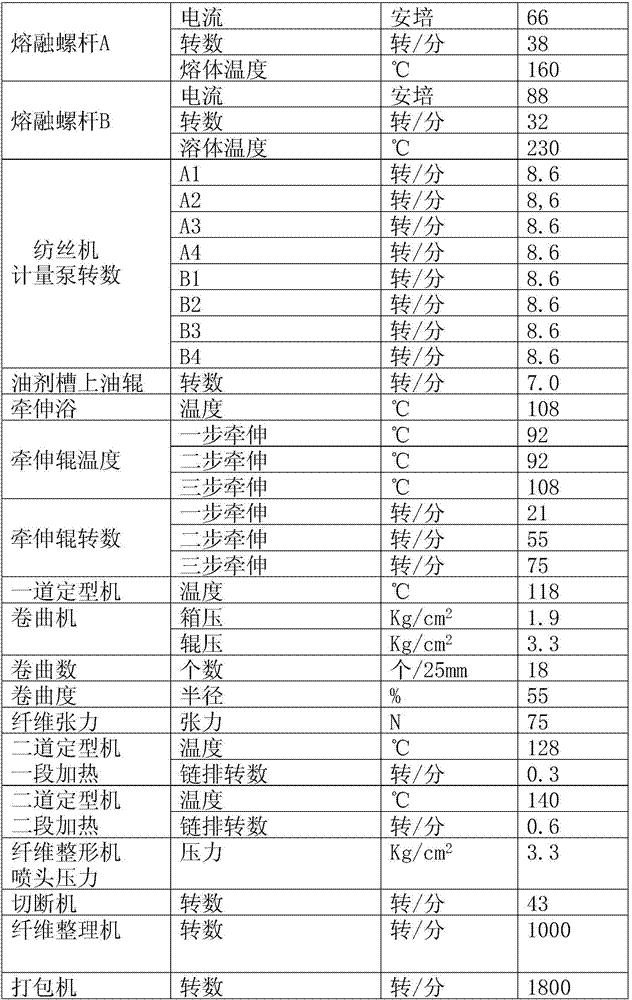

[0018] Step 1. Add polypropylene slices with a melt index of 72g / 10min into the melting screw A as the skin layer. The temperature of each zone of the melting screw A is: 160℃~170℃ in zone 1, 170℃~180℃ in zone 2, 180℃~ in zone 3 190℃, 182℃~200℃ in zone 4, 185℃~230℃ in zone 5, 185℃~230℃ in zone 6, 185℃~230℃ in zone 7; the melt temperature of melting screw A is 160℃~230℃; The number is 38 rpm to 52 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com