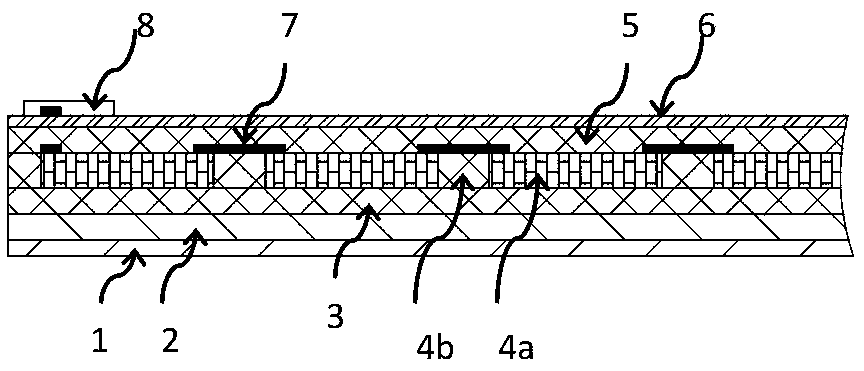

Photovoltaic module based on perovskite solar cells and packaging method thereof

A technology of solar cells and photovoltaic modules, applied in electrical components, photovoltaic power generation, electric solid-state devices, etc., can solve the problems of inflexible control of open-circuit voltage and current density, reduce effective use area, facilitate installation, and improve mechanical resistance effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The packaging of single perovskite solar cells, in which only one cell is made on a single cell.

[0075] (1) At one end of the FTO glass substrate, an insulating line is etched with a laser, and the FTO is divided into two ends with a large area and a small area. Subsequent processes are carried out at the end of the large area until carbon brushing.

[0076] (2) Clean the FTO glass with acetone, alkaline detergent, deionized water, and acetone ultrasonically for ten minutes, and finally blow dry.

[0077] (3) Preparation of TiO on FTO glass substrate 2 For the dense layer, the solvent of the precursor solution is ethanol and water, which includes the following components: tetraisopropyl titanate (0.3mol / L), acetylacetone (0.45mol / L), and hydrochloric acid (0.09mol / L). Absorb the precursor solution, drop it on the cleaned FTO substrate, make the solution cover the entire FTO surface, and form a film by spin coating, the spin coating speed is 3000rpm, and the time is 2...

Embodiment 2

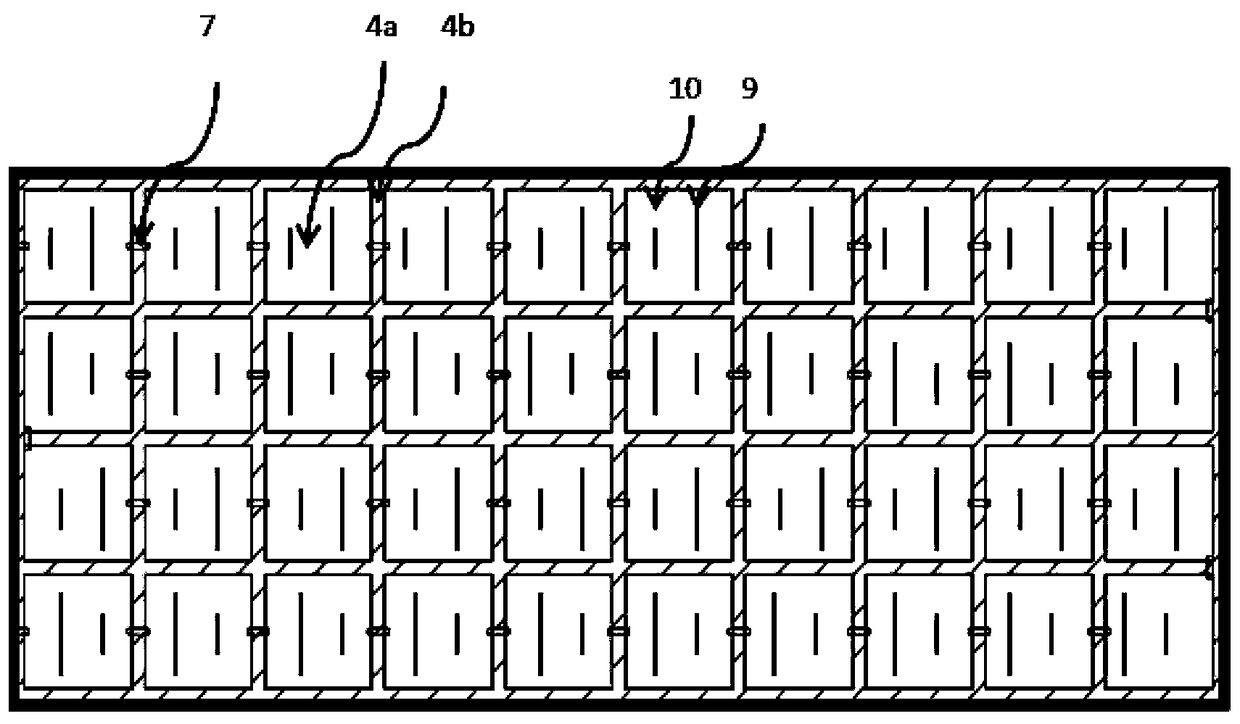

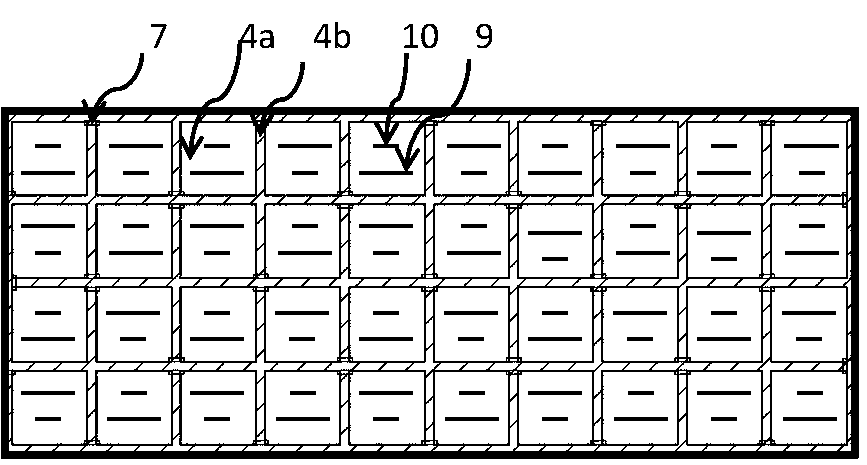

[0087] Single-cell perovskite solar module components are manufactured, in which only multiple cells are connected in series and parallel on a single cell, so it is called a single-cell perovskite solar module.

[0088] (1) On the FTO glass substrate, use a laser to etch insulated wires, and divide the FTO into several small units with equal areas.

[0089] (2) Clean the FTO glass with acetone, alkaline detergent, deionized water, and acetone ultrasonically for ten minutes, and finally blow dry.

[0090] (3) Preparation of TiO on FTO glass substrate 2 For the dense layer, the solvent of the precursor solution is ethanol and water, which includes the following components: tetraisopropyl titanate (0.3mol / L), acetylacetone (0.45mol / L), and hydrochloric acid (0.09mol / L). Absorb the precursor solution, drop it on the cleaned FTO substrate, make the solution cover the entire FTO surface, and form a film by spin coating, the spin coating speed is 3000rpm, and the time is 20s. Sinte...

Embodiment 3

[0102] Fabrication of perovskite solar cell tandem structure photovoltaic modules.

[0103] (1) On the FTO glass substrate, use a laser to etch insulated wires, and divide the FTO into several small units with equal areas.

[0104] (2) Clean the FTO glass with acetone, alkaline detergent, deionized water, and acetone ultrasonically for ten minutes, and finally blow dry.

[0105] (3) Preparation of TiO on FTO glass substrate 2 For the dense layer, the solvent of the precursor solution is ethanol and water, which includes the following components: tetraisopropyl titanate (0.3mol / L), acetylacetone (0.45mol / L), and hydrochloric acid (0.09mol / L). Absorb the precursor solution, drop it on the cleaned FTO substrate, make the solution cover the entire FTO surface, and form a film by spin coating, the spin coating speed is 3000rpm, and the time is 20s. Sintered at 510°C for 30 min in a muffle furnace.

[0106] (4) On the dense layer, screen-print titanium dioxide slurry as an electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com