Production technology for novel ultra-thin high-strength low-stretch-rate spunlace sanitation material

A production process, ultra-thin technology, used in non-woven fabrics, textiles and papermaking, etc., can solve the problems of large thickness, low strength, uneven web formation, etc., achieve low melting point, improve strength, and improve web unevenness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

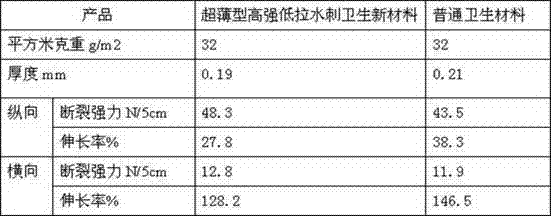

Image

Examples

Embodiment 1

[0018] The production process of the ultra-thin high-strength and low-strength spunlace sanitary new material of the present invention specifically includes the following: the mixed fiber of ES fiber, viscose fiber and polyester fiber is selected as the raw material, and fed into the long curtain, horizontal opener, large Warehouse mixing box, fine opener, cotton storage box, airflow cotton box, carding machine, spunlace machine, dryer, on-line detection device, coiling device. In the mixed fiber, the weight percentage of ES fiber is 10%, the weight percentage of viscose fiber is 50%, and the weight percentage of polyester fiber is 40%.

[0019] Wherein, the main cylinder working roll in the carding machine is 75m / min, the main cylinder stripping roller is 130m / min, and the main cylinder rotating speed is 1050 m / min.

[0020] The fiber web output by the carding machine adopts straight laying.

[0021] A total of 5 spunlace heads are installed on the spunlace machi...

Embodiment 2

[0024] The production process of the ultra-thin high-strength and low-strength spunlace sanitary new material of the present invention specifically includes the following: the mixed fiber of ES fiber, viscose fiber and polyester fiber is selected as the raw material, and fed into the long curtain, horizontal opener, large Warehouse mixing box, fine opener, cotton storage box, airflow cotton box, carding machine, spunlace machine, dryer, on-line detection device, coiling device. In the mixed fiber, the weight percentage of ES fiber is 10%, the weight percentage of viscose fiber is 50%, and the weight percentage of polyester fiber is 40%.

[0025] Wherein, the main cylinder working roll in the carding machine is 90m / min, the main cylinder stripping roller is 130m / min, and the main cylinder rotating speed is 1050 m / min.

[0026] The fiber web output by the carding machine adopts straight laying.

[0027] A total of 5 spunlace heads are installed on the spunlace machi...

Embodiment 3

[0030] The production process of the ultra-thin high-strength and low-strength spunlace sanitary new material of the present invention specifically includes the following: the mixed fiber of ES fiber, viscose fiber and polyester fiber is selected as the raw material, and fed into the long curtain, horizontal opener, large Warehouse mixing box, fine opener, cotton storage box, airflow cotton box, carding machine, spunlace machine, dryer, on-line detection device, coiling device. In the mixed fiber, the weight percentage of ES fiber is 10%, the weight percentage of viscose fiber is 50%, and the weight percentage of polyester fiber is 40%.

[0031] Wherein, the main cylinder working roll in the carding machine is 100m / min, the main cylinder stripping roller is 130m / min, and the main cylinder rotating speed is 1050 m / min.

[0032] The fiber web output by the carding machine adopts straight laying.

[0033] A total of 5 spunlace heads are installed on the spunlace mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com