Non-woven fabric for semipermeable membrane support body

A technology of support and non-woven fabrics, which is applied in the field of non-woven fabrics for semi-permeable membrane supports, can solve the problems of non-woven fabrics such as decreased air permeability, poor fit, and too subjective solutions, so as to prevent the penetration of coating liquid Good performance, simplified processing equipment and process, excellent smoothness and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

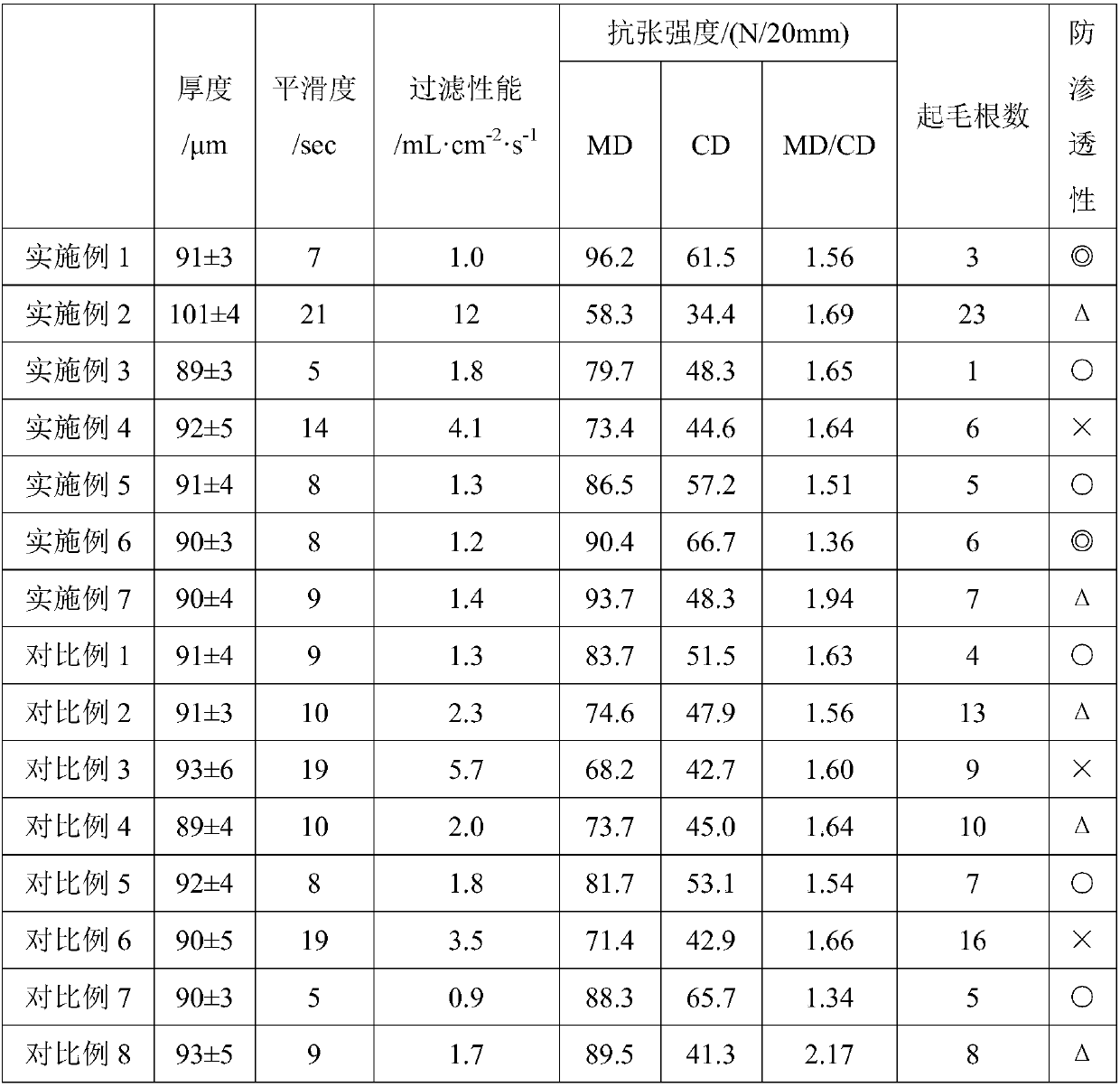

Examples

preparation example Construction

[0041] The preparation method of the wet-laid non-woven fabric is first to disperse the main fiber, two kinds of binder fibers and the dispersant in water, and configure it into a uniform slurry with a concentration of 1wt% to 2.5wt% through a beater, after screening, removing impurities After other procedures, transfer to the pulp storage tank. Add the diluted wet strength agent into the slurry tank and stir evenly. Then transport the slurry to the headbox, further dilute the slurry to 0.01wt%-0.05wt%, according to the foam condition of the slurry, add defoamer appropriately, and make paper with a paper machine. In order to improve the uniformity of wet paper, additives such as tackifier and antistatic agent can be added appropriately in the above process.

[0042] As a beater, its main function is to loosen fibers under mechanical, shear, friction, hydraulic impact, etc. in the beating equipment, and finally form a dispersed and well-distributed slurry. In this patent, the...

Embodiment 1

[0072] PET main fiber (fiber diameter 9μm, fiber length 5mm, melting point 255°C, accounting for 65% of the total fiber mass), unstretched PET binder fiber (fiber diameter 12μm, fiber length 5mm, melting point 230°C, accounting for the total fiber 20% of the mass), sheath-core structure polyester binder fiber (fiber diameter 8 μm, fiber length 5mm, melting point 220 ° C, skin / core mass ratio is 50 / 50, accounting for 15% of the total fiber mass), dispersant PEO (4 million molecular weight, accounting for 0.005% of the mass of the aqueous solution), wet strength agent PAE (0.6% of the total fiber mass), and an alcohol defoamer (0.4% of the total fiber mass) are dispersed in water. Paper is made by inclined wire paper machine (inclination angle is 15°, papermaking speed is 25m / min). After drying and hot pressing, the grammage is 80g / m 2 nonwoven samples.

Embodiment 2

[0074]PET main fiber (fiber diameter 9 μm, fiber length 5 mm, melting point 255 ° C, accounting for 80% of the total fiber mass), unstretched PET binder fiber (fiber diameter 12 μm, fiber length 5 mm, melting point 230 ° C, accounting for the total fiber 10% of the mass), sheath-core structure polyester binder fiber (fiber diameter 8 μm, fiber length 5mm, melting point 220 ° C, skin / core mass ratio is 50 / 50, accounting for 10% of the total fiber mass), dispersant PEO (4 million molecular weight, accounting for 0.005% of the mass of the aqueous solution), wet strength agent PAE (0.6% of the total fiber mass), and an alcohol defoamer (0.4% of the total fiber mass) are dispersed in water. Paper is made by inclined wire paper machine (inclination angle is 15°, papermaking speed is 25m / min). After drying and hot pressing, the grammage is 80g / m 2 nonwoven samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com