Patents

Literature

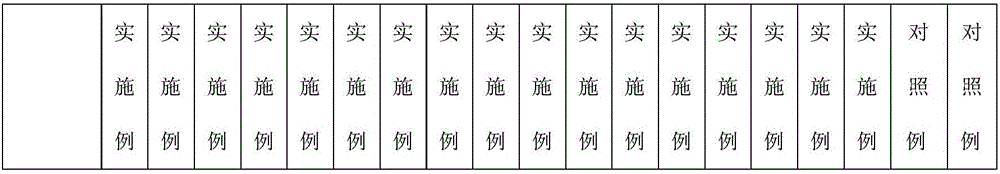

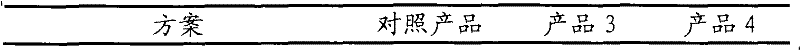

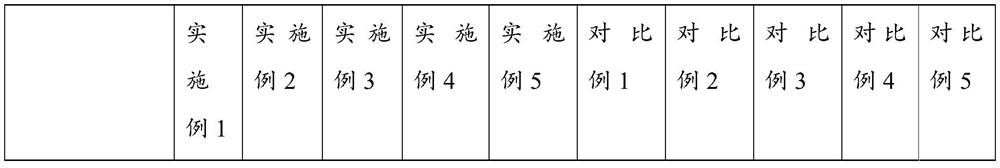

42results about How to "Adjust surface tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano dye ink for ink jet printing and preparation method thereof

InactiveCN1687258AGuaranteed long-term stabilityAdjust surface tensionInksPrintingInk printerPrinting ink

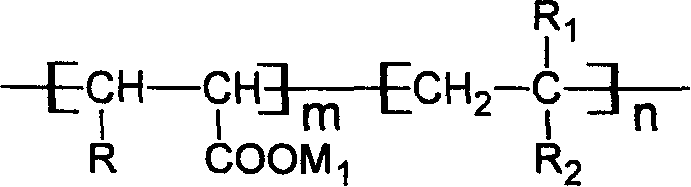

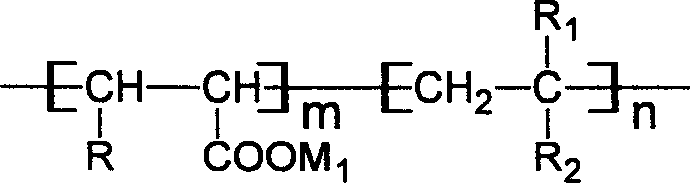

The present invention relates to a nano pigment spray-printing ink for computer ink jet printer and colour spray plotter. Said invention adopts a high-molecular dispersing agent to modify pigment surface so as to make the pigment be stably dispersed in water medium, and adds several water-soluble cosolvents to prepare a set of colour inks, including red, yellow, blue and black four inks.

Owner:JIANGNAN UNIV

Dyeing liquor for dental ceramics

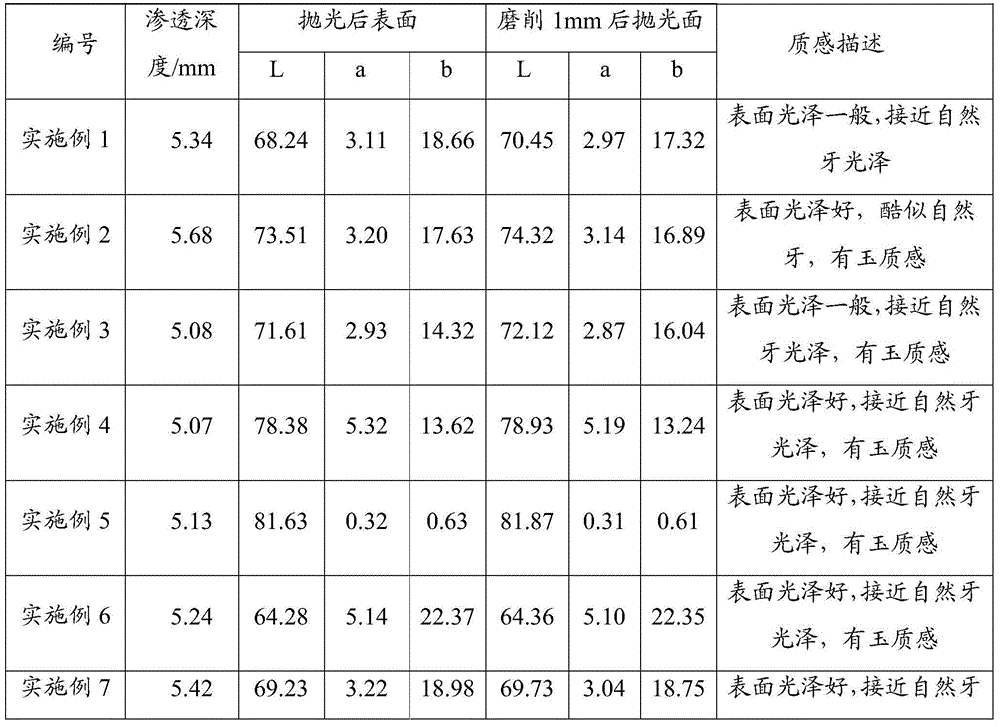

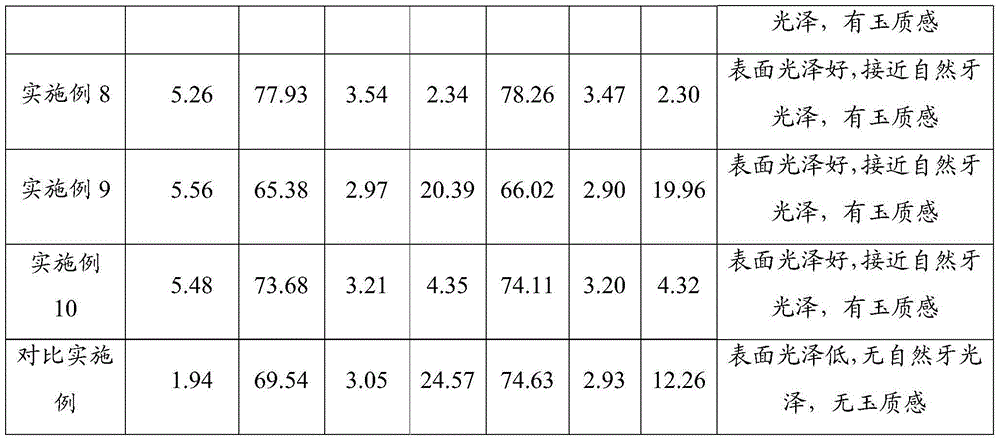

The invention provides dyeing liquor for dental ceramics. The dyeing liquor for dental ceramics comprises a solvent, a coloring agent and an organic addition agent. Compared with the conventional dyeing liquor in the prior art, the dyeing liquor for dental ceramics, provided by the invention, has the characteristics as follows: (1), the dyeing liquor self needs to be stabilized, is harmless to human bodies or causes less damage; (2), the depth of penetration of the dyeing liquor to dental ceramics needs to be sufficient, and the depth of dyeing penetration to pre-sintering green bodies needs to be greater than 5mm; (3), the dyeing liquor needs to be uniform in dyeing the dental ceramics in the surface or in the direction perpendicular to the surface, that is, the dental ceramics, after being subjected to localized grinding or finishing at different parts with different grinding amounts, can still be uniform in color; (4), at the same time, inorganic ions are added to the dyeing liquor, so that an optical effect of the dental ceramics is obviously improved, and a sense of quality similar to that of natural teeth is achieved.

Owner:NANCHONG THREE CIRCLE ELECTRONICS +1

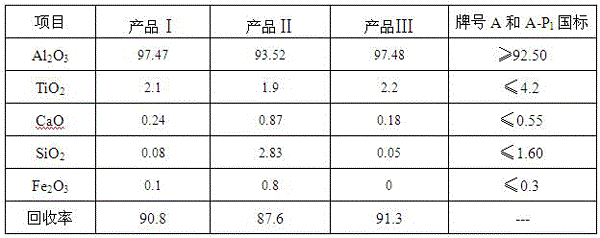

Method of melting aluminum ash to prepare brown aluminum oxide

InactiveCN106747301AAchieving processing powerImplement resourcesCeramic materials productionClaywaresCoesiteHigh-temperature corrosion

The invention discloses a method of melting aluminum ash to prepare brown aluminum oxide. At first, aluminum ash is subjected to an acidification treatment and an alkalization treatment in sequence; then solid-liquid separation is performed to obtain aluminum ash; the obtained aluminum ash is subjected to drying dehydration and high temperature burning; after the aluminum ash is cooled, the aluminum ash is mixed with iron chips and coke, and finally the mixture is sintered to obtain brown aluminum oxide. In the melting step, burned aluminum ash, iron chips, and coke are mixed according to a ratio of 100:3-4:8-13, the mixture is melted for 2 to 3 hours at a high temperature of 2300 to 2700 DEG C, and finally the mixture is ground and graded to obtain the brown aluminum oxide. The aluminum ash is subjected to a harmless treatment and converted into valuable resources. The problem of shortage of high aluminum bauxite is solved, and the production cost of brown aluminum oxide is also reduced.

Owner:HENAN UNIV OF SCI & TECH

Oily digital ink-jet printing thermal sublimation printing ink and preparation method thereof

The invention relates to oily digital ink-jet printing thermal sublimation printing ink and a preparation method thereof. The printing ink comprises the following components in percentage by mass: 1 to 10 percent of disperse dyes, 0.5 to 15 percent of resin, 1 to 15 percent of polymer dispersant and 60 to 95 percent of oily dispersion medium. The preparation method thereof comprises the following steps: stirring 0.5 to 15 percent of resin, 1 to 15 percent of polymer dispersant and 60 to 95 percent of mineral oil, adding 1 to 10 percent of disperse dyes into the mixture for grinding to prepare color paste; and after stirring and mixing 10 to 100 percent of color paste with 0 to 90 percent of oily dispersion medium fully and uniformly, filtering the mixture by 0.2 to 2 mu m of filter to prepare the oily digital ink-jet printing thermal sublimation printing ink. The printing ink has the advantages of excellent moisture retention, storage stability, spit fluency, and simple preparation process.

Owner:上海英威喷墨科技有限公司

Silver paste suitable for spraying of ceramic filter, and preparation and spraying film forming methods of silver paste

ActiveCN112071466AStable storageLow viscosityApparatus for manufacturing conducting/semi-conducting layersNon-conductive material with dispersed conductive materialSilver pasteAcrylic resin

The invention discloses a silver paste suitable for spraying of a ceramic filter. The silver paste comprises the following components in percentage by mass: 75-82% of silver powder, 0.2-3% of glass powder, 0.5-1% of an aging adhesion promoter, 8-14% of resin, 7-15% of an organic solvent and 1-3% of an assistant, wherein the resin is hydroxyl acrylic resin with a molecular weight of 1000-5000 and aviscosity of 1000-4000 mPa.S. The invention further discloses a preparation method and a spraying film forming method of the silver paste suitable for surface spraying of the ceramic filter. According to the silver paste, storage stability is enhanced, the silver paste can adapt to metallization of the surface of a special-shaped ceramic filter with a complex structure, the strength of a dried silver paste film is improved, and the adhesive force between the silver film and the ceramic surface of the filter is improved. The preparation process and the spraying process of the silver paste aresimple, the sintered silver film is firm, not prone to falling off and uniform in thickness, and the silver paste can adapt to mass production of ceramic filters.

Owner:JIANGSU HOYI TECH

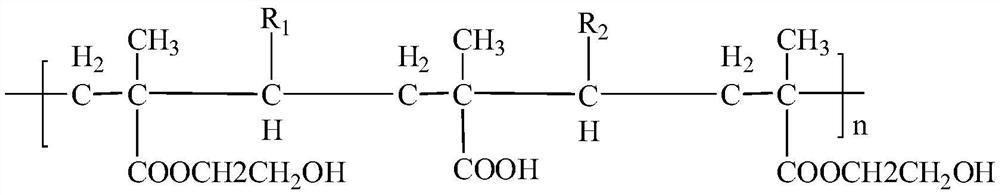

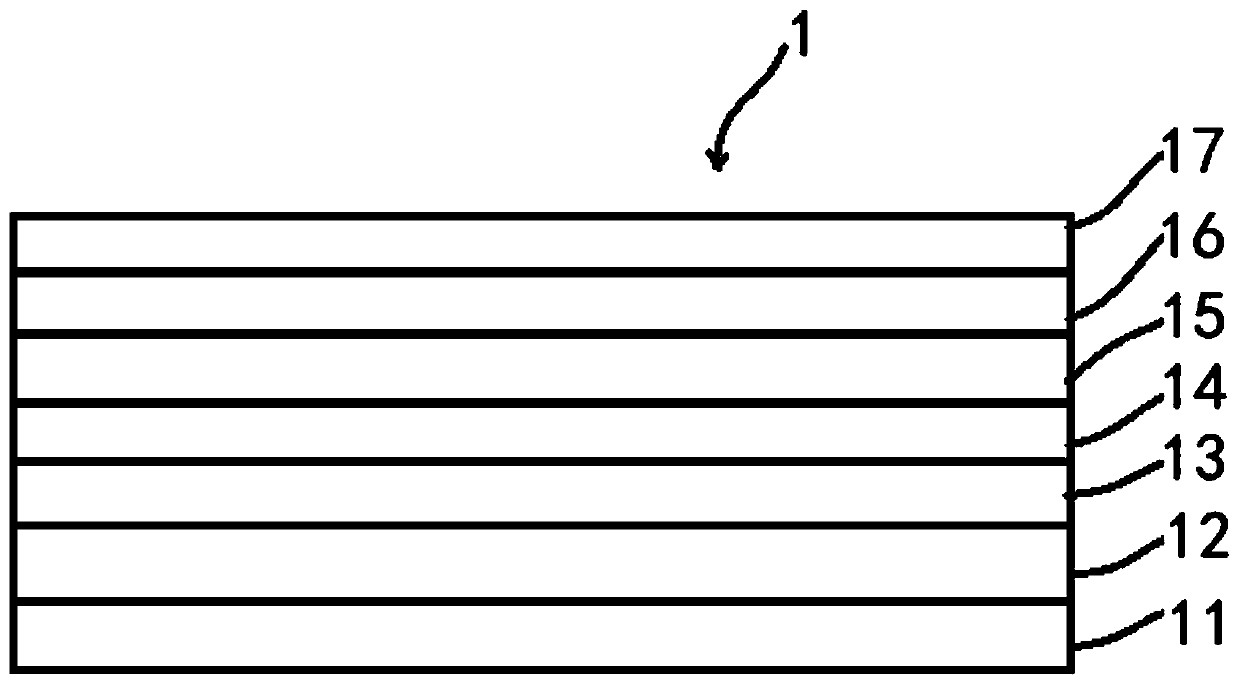

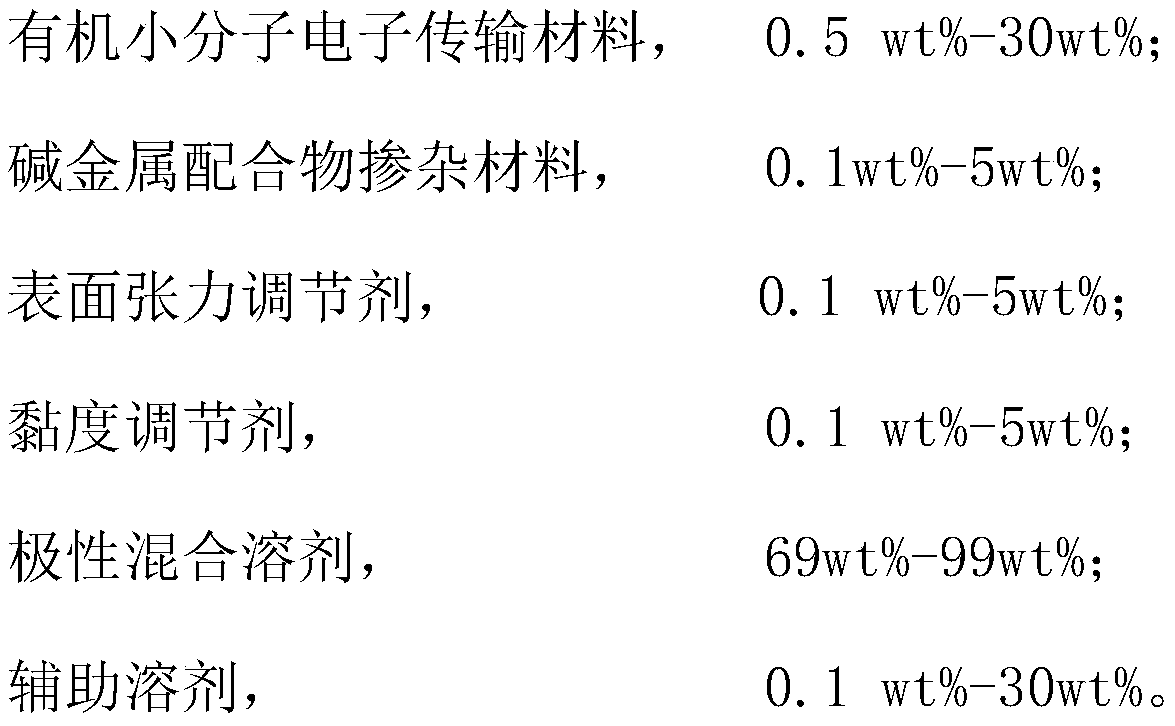

Electron transport layer ink, preparation method thereof and electroluminescence device

InactiveCN110172275AEasy injectionImprove transmission performanceSolid-state devicesSemiconductor/solid-state device manufacturingSolventElectron transport layer

The invention discloses an electron transport layer ink, a preparation method thereof and an electroluminescence device. The electron transport layer ink is prepared from, by weight, 0.5-30% of an organic micro-molecular electron transport material, 0.1-5% of an alkali metal complex doping material, 0.1-5% of a surface tension modifier, 0.1-5% of a viscosity modifier, 69-99% of a polar mixed solvent and 0.1-30% of an auxiliary solvent. The electron transport layer ink, the preparation method thereof and the electroluminescence device have the advantages that the prepared electron transport layer ink can be formed in an electron transport layer through a printing technology, and the solvent in the electron transport layer ink can also be prevented from destroying the lower luminescent layer.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

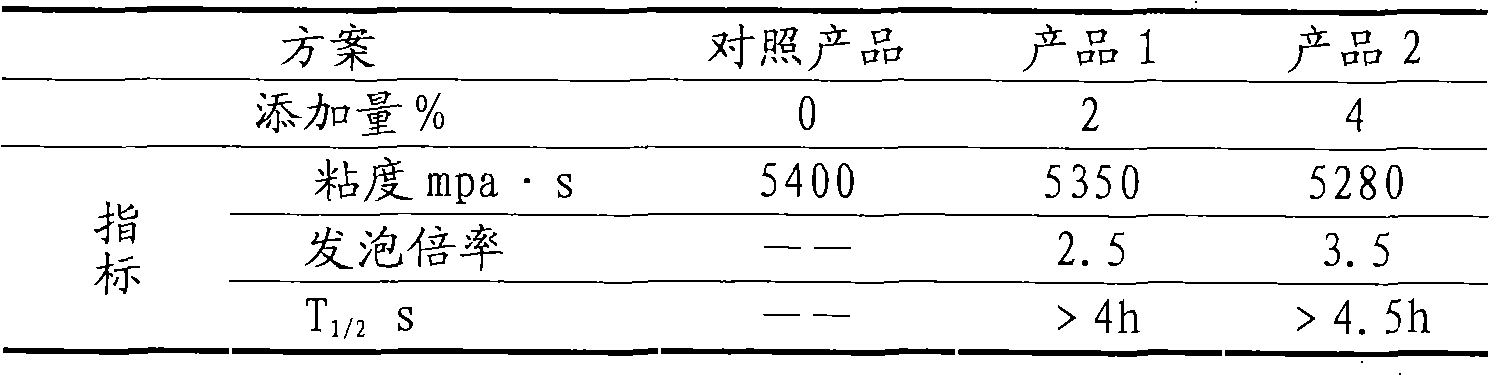

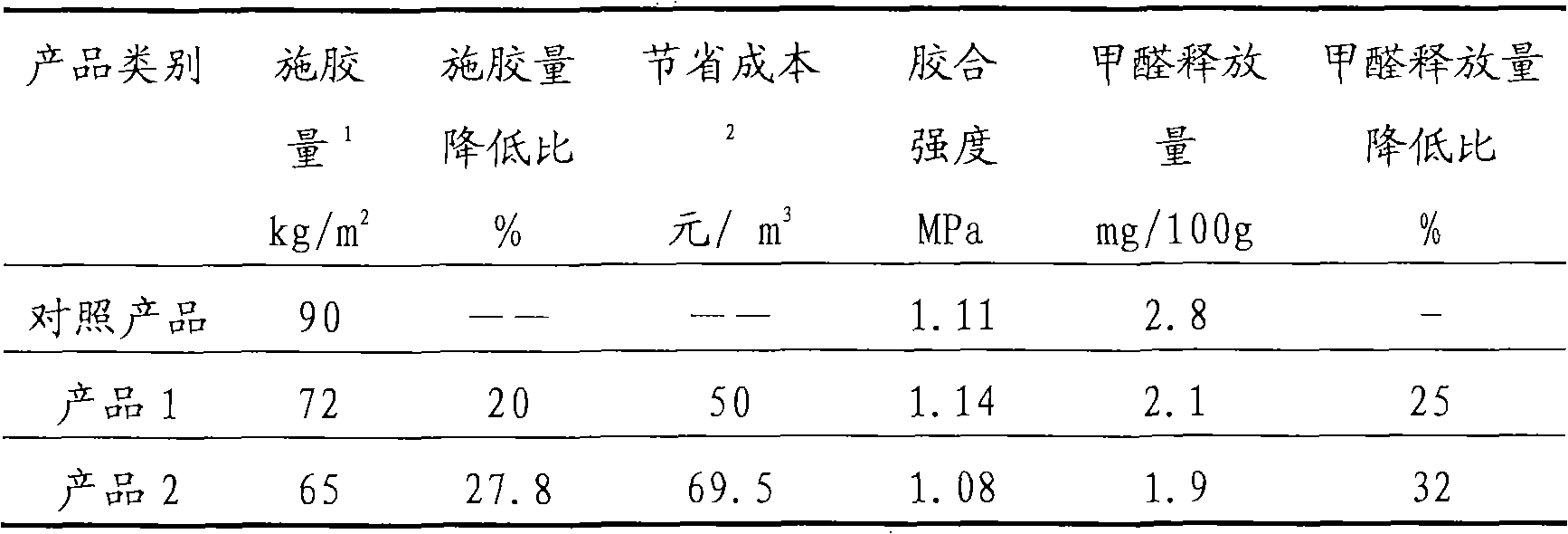

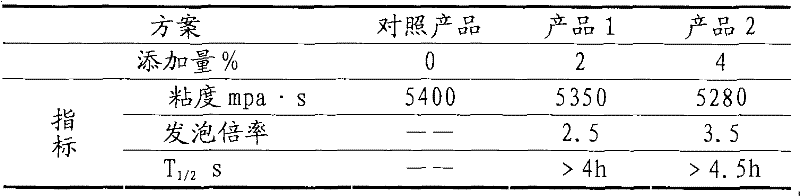

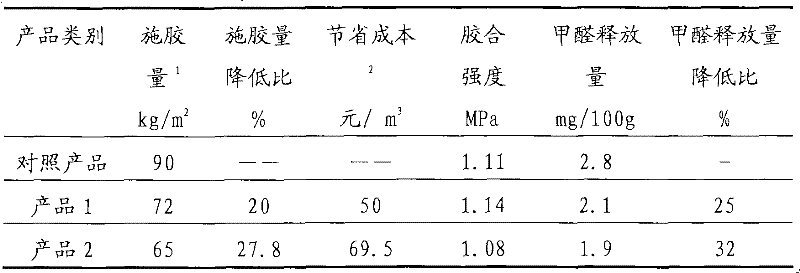

Composite foaming agent for urea-formaldehyde resin, preparing method and application thereof

InactiveCN101586014AReduce clumpingImprove liquidityNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesLong lastingAdverse effect

The present invention discloses a composite foaming agent for urea-formaldehyde resin, a preparing method and an application thereof. The composite foaming agent of the invention is composed of a foaming agent, a foam stabilizer and a dispersing agent. After the composite foaming agent is added into the urea-formaldehyde resin additive, the volume of the urea-formaldehyde resin can be increased for 2-3 times for forming the fine, uniform and long-lasting foamed urea-formaldehyde resin, effectively regulating the surface tension of the glue solution, reducing the conglobation phenomenon of flour, increasing the fluidity of the urea-formaldehyde resin, settling the adverse phenomena of glue bleeding, glue leakage, non-homogeneous adhesive layer, etc. which commonly exist in the prior urea-formaldehyde resin adhesive, so that the urea-formaldehyde resin on the plate blank of the veneer board has excellent homogeneity and the bleeding balancing is kept and the total usage of flour and the urea-formaldehyde resin after adhesive mixing is reduced for 10-30%. Additionally, the composite foaming agent of the invention has the advantages of excellent safety, no adverse effect in the using process and capability for effectively reducing the release amount of the formaldehyde of the artificial board. Furthermore the mechanical properties of the prepared artificial board can equally obtain the requirement of the national standard.

Owner:EVERFIRST WISEFUND TECH BEIJING

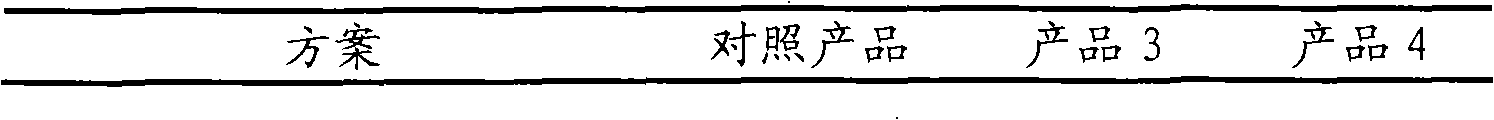

Preparation method of reinforcing and toughening lubricant specially used for ABS

The invention belongs to the technical field of lubricants, and in particular relates to a preparation method of a reinforcing and toughening lubricant specially used for ABS. The method comprises thefollowing steps: firstly nano powder is added into ethanol, a treating agent is added to modify the surface of the powder, the obtained treated nano powder is added into ethylenediamine to obtain aminated nano powder, the aminated nano powder and stearic acid are subjected to a reaction at high temperature to obtain a waxy substance, glass cellulose modified by glyceryl monostearate can be addedinto the waxy substance, extrusion granulation is performed, and therefore the reinforcing and toughening lubricant specially used for the ABS can be obtained. According to the method provided by theinvention, the prepared lubricant is added into the ABS resin, and the lubricant has good compatibility with the ABS resin, and improves the impact strength and bending strength of the ABS resin whileimproving the fluidity of the ABS resin.

Owner:常州可赛成功塑胶材料有限公司

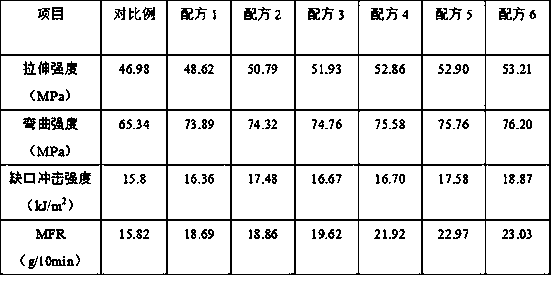

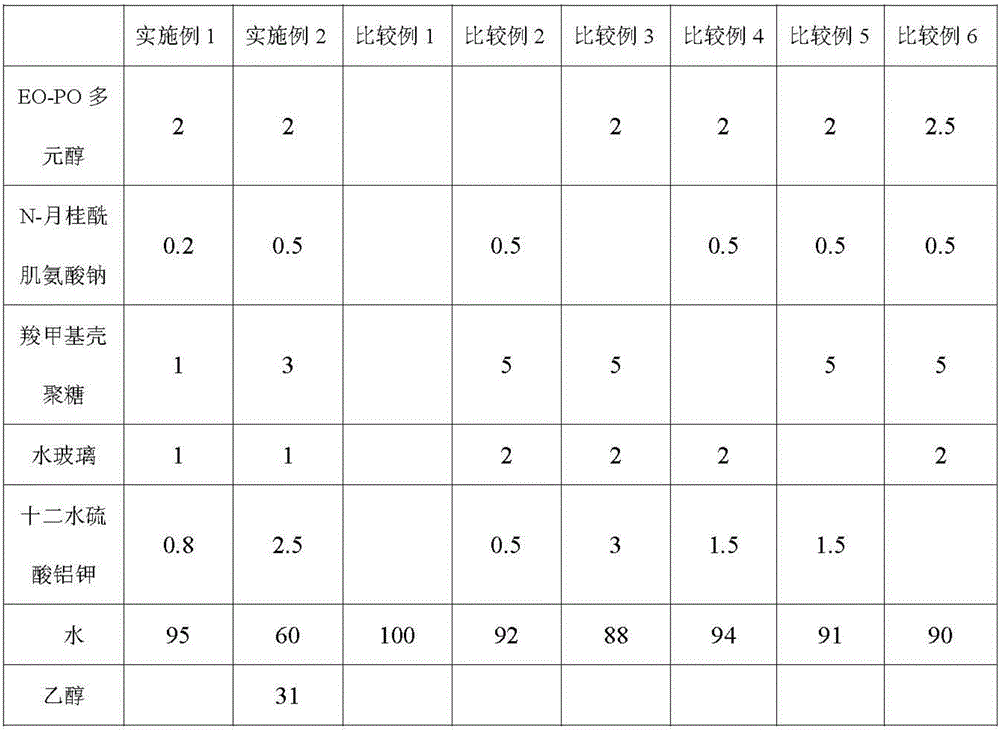

Novel material capable of quickly settling suspended particulates

The invention discloses a novel material capable of quickly settling suspended particulates. The novel material capable of quickly settling suspended particulates comprises a wetting agent, a foaming agent, a coating agent, an adhesive, a settling agent and a dispersing agent. The wetting agent is EO-PO polylol; the foaming agent is sodium N-lauroyl sarcosinate; the coating agent is carboxymethyl chitosan; the adhesive is water glass; the settling agent is aluminum potassium sulfate dodecahydrate; and the dispersing agent is a water-ethanol mixture. The wetting agent can wet suspended particulates with different compositions and particle sizes, and adjust the surface tension. The foaming agent can increase the collision capture probability between the material and suspended particulates. The coating agent can be coated on the suspended particulates to firmly capture the suspended particulates, thereby avoiding secondary pollution. The adhesive can enhance the bonding strength between the suspended particulates and the material disclosed by the invention. The settling accelerant can aggregate the coated and bonded suspended particulates, thereby accelerating settling. The removal effect of suspended particulates is greatly enhanced by using the principles of wetting, foaming, coating, bonding and settling acceleration.

Owner:陈永 +1

Waterborne digital ink-jet printing sublimation ink and preparation method thereof

ActiveCN101709177BNot easy to gatherGood storage stabilityInksDyeing processDisperse dyeOrganic solvent

The invention provides waterborne digital ink-jet printing sublimation ink and a preparation method thereof. The ink comprises the following components in percentage by mass: 1 to 10 percent of disperse dye, 2 to 15 percent of dispersing agent, 10 to 60 percent of deionized water, 10 to 50 percent of water soluble organic solvent, 0.1 to 5 percent of surface active agent, 0.05 to 0.5 percent of germicide, and 0.05 to 0.5 percent of defoaming agent. The preparation method comprises the following steps of: mixing 1 to 20 percent of dispersing agent, 10 to 40 percent of water soluble organic solvent, 0.1 to 2 percent of germicide, 0.1 to 2 percent of defoaming agent, and 30 to 50 percent of deionized water, adding 1 to 20 percent of disperse dye while stirring, and grinding the mixed solution to obtain color paste; uniformly mixing 15 to 50 percent of color paste, 10 to 30 percent of water soluble organic solvent, 0.1 to 5 percent of surface active agent and 20 to 50 percent of deionizedwater and filtering the mixed solution to obtain the waterborne digital ink-jet printing sublimation ink. When the waterborne digital ink-jet printing sublimation ink is used in a large-sized ink-jetprinter using waterborne ink, the good printing smoothness and the water retention of a printing head are achieved, and the preparation process is simple.

Owner:上海英威喷墨科技有限公司

Preparation method for alumina-based foam material

The invention discloses a preparation method for an alumina-based foam material. The method comprises the following steps: firstly, plating a layer of metal on the surface of carbon fiber, and adding the carbon fiber with the metal coating into aluminum or aluminum alloy fusant; then adding titanium hydride, and stirring evenly; and taking the carbon fiber out after foaming, and cooling to obtainthe alumina-based foam material with enhanced fiber. In the invention, the carbon fiber is introduced into the preparation of the foamed aluminum material, thereby realizing that the stability of bubbles and material performance are improved; and compared with the prior art, the compressive strength of the foamed aluminum material prepared by the invention is higher than 6Mpa, the impact toughness is improved by about 30%, and the energy absorption capability is improved by more than 50%, thus the compression strength, the energy absorbing and damping performances of the alumina-based foam material with short enhanced carbon fiber are remarkably improved, and the pore wall toughness of the material is better.

Owner:NORTHEASTERN UNIV LIAONING

Cleaning liquid of semiconductor chip after chemical mechanical grind

InactiveCN100549236CGood removal effectEasy to removeSemiconductor/solid-state device manufacturingSemiconductor chipSurface-active agents

A kind of cleaning solution for semiconductor chip after chemo-mechanical grind. Contents of it are as follow, water, 100 part by weight; chelator, 0.01-4 part by weight; brightener, 0.001-2 part by weight; conserving agent,0.0005-0.1 part by weight; buffering agent,0.001-4 part by weight; surface active agent,0.001-1 part by weight. And pH is 1-7.

Owner:杭州月旭科学仪器有限公司

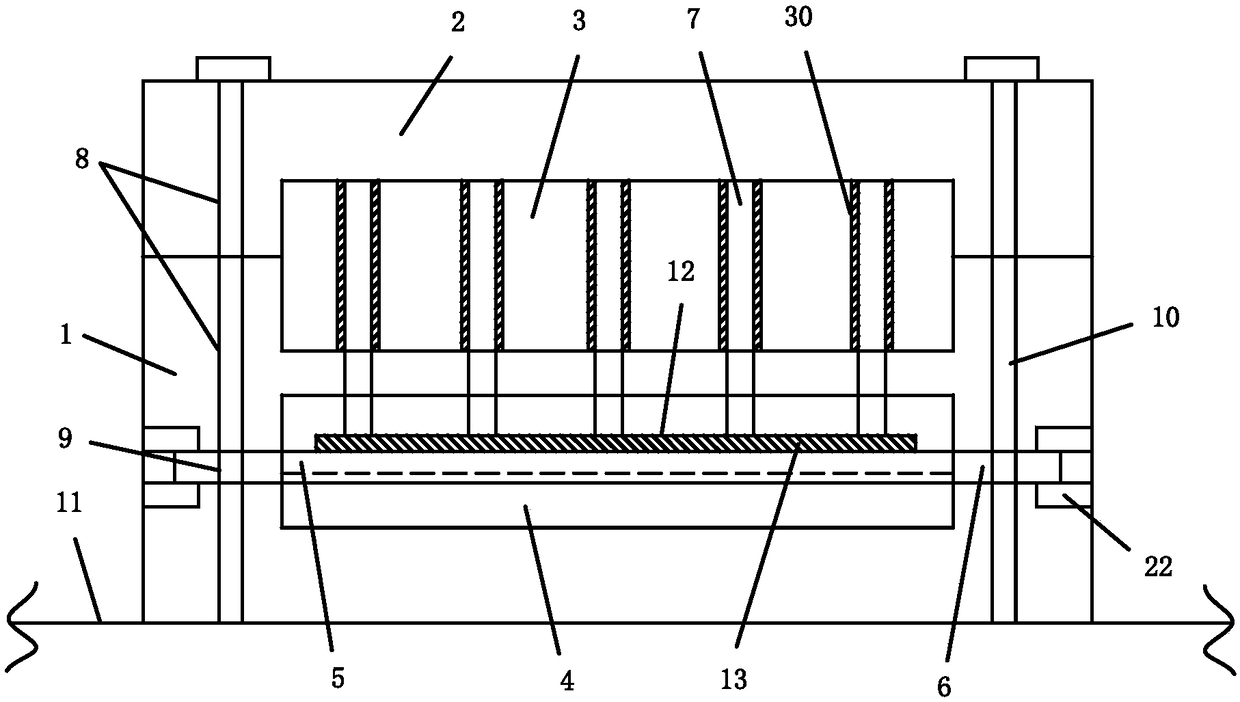

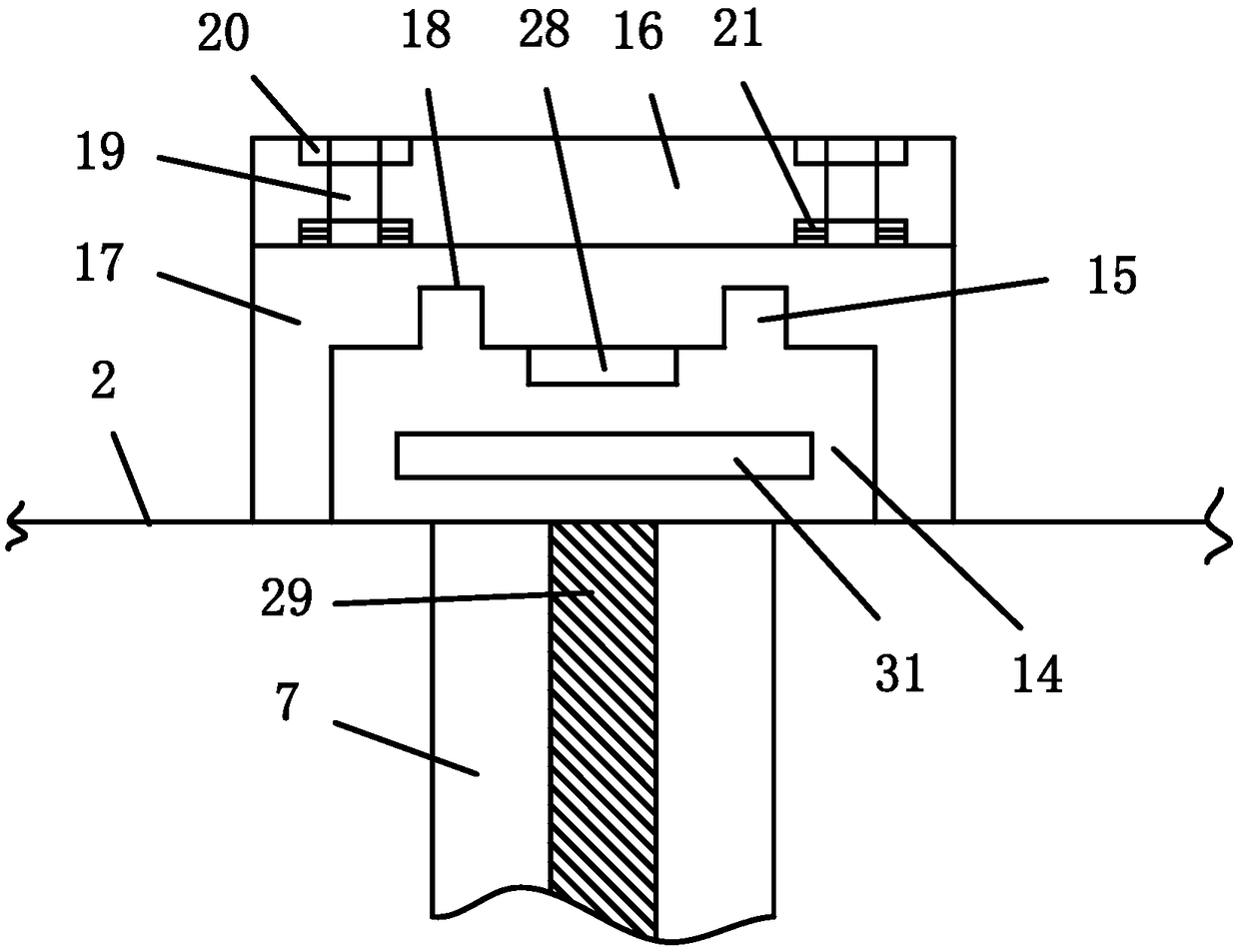

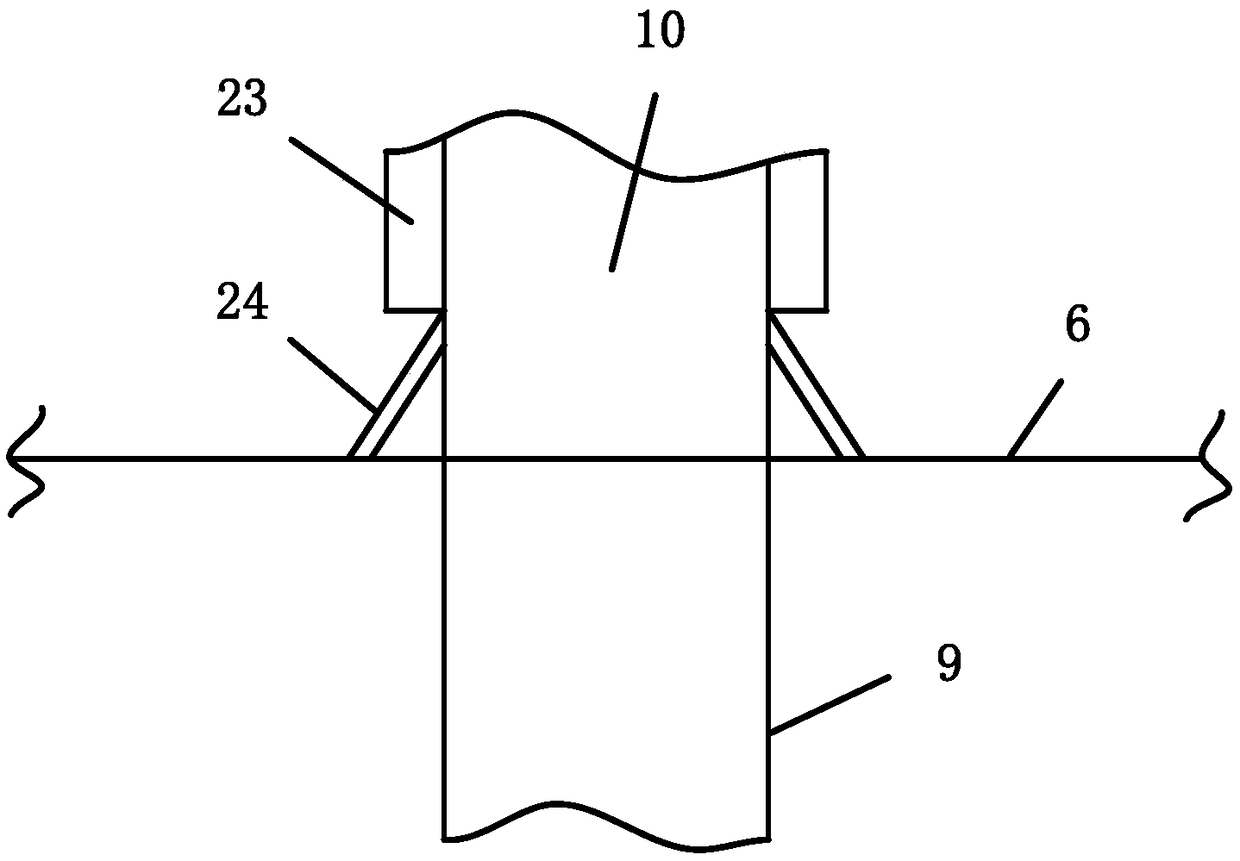

Thickening damping type high-speed railway II type track plate and construction technology thereof

ActiveCN109338828AHigh precisionReduce shock absorptionRailway track constructionSheet steelArchitectural engineering

The invention discloses a thickening damping type high-speed railway II type track plate. The thickening damping type high-speed railway II type track plate comprises a base, wherein a track plate body is fixed to the top of the base, a gap is arranged between the base and the track plate body, and the void is filled with a cement asphalt mortar layer; a cavity is formed in the base, a steel plateis installed in the cavity, and inserting blades are fixed to the two ends of the steel plate; the inserting blades are fixedly connected in the base in an inserting mode, a plurality of locating columns are fixed to the steel plate, and the locating columns are fixedly connected to the bottom surface of the track plate body after penetrating through the cement asphalt mortar layer; first vertical through holes are formed in the two ends of the base and the track plate body; second through holes, corresponding to the first through holes, are formed in the inserting blades; and a fixing bolt is fixedly connected with the base after penetrating through the first through holes and the second through holes. The thickening damping type high-speed railway II type track plate can improve the deficiencies in the prior art, and improve the damping performance of the track plate.

Owner:HUNAN UNIV OF SCI & ENG

Abrasion-resistant scratch-proof coating and preparation method thereof

The invention discloses abrasion-resistant scratch-proof coating and a preparation method thereof. The coating is prepared from the following components in parts by weight: 100-120 parts of a film forming agent, 30-50 parts of filler, 25-45 parts of a diluting agent, 1-5 parts of a defoaming agent and 30-50 parts of a curing agent, wherein the filler is mixture of SiC and sodium benzenesulfonate coated polymer. The coating has the characteristics of large hardness, abrasion resistance, scratch resistance, strong adhesion and the like, has the hardness to be over 6H and adhesion to be zero grade, and can avoid the problems of coating cracking, peeling, falling and the like, and improve the coating construction performance, so that the technical problems of poor filler dispersibility, low hardness of coating, easily scratched coating and poor adhesion can be solved. The preparation method is simple and easily controllable in operation, can easily realize industrial production, and has anexcellent application prospect.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +1

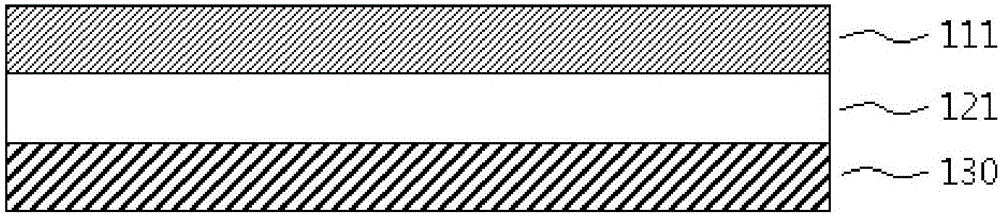

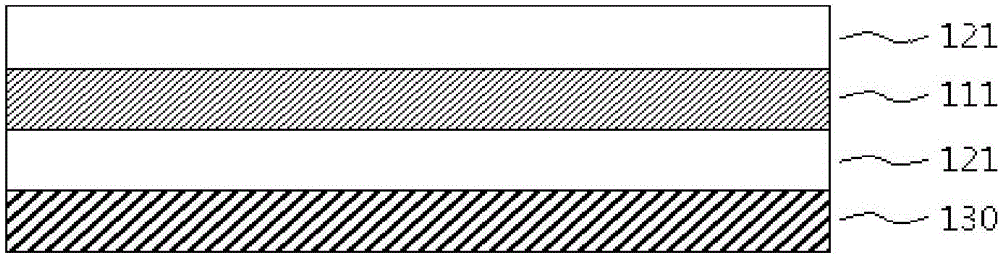

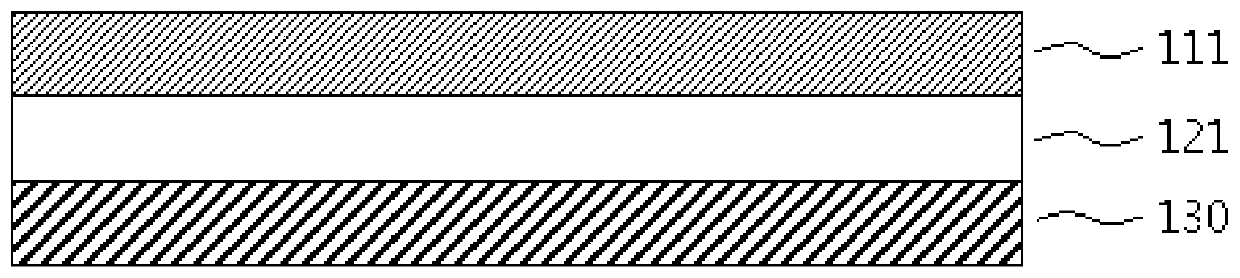

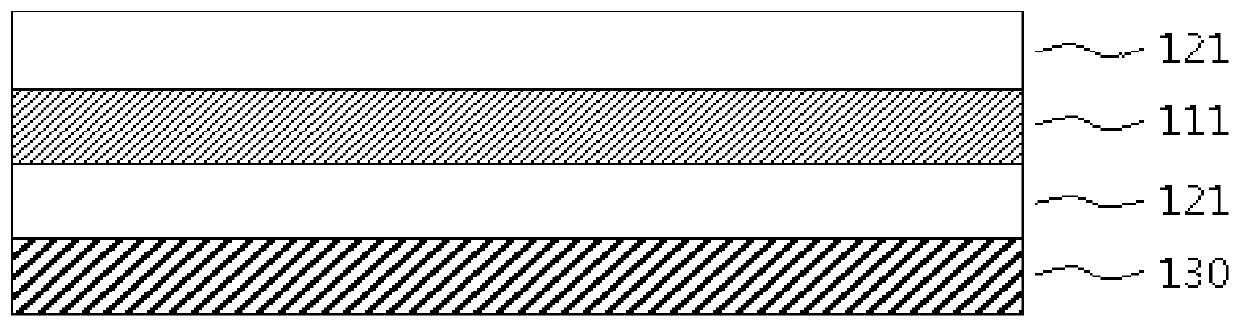

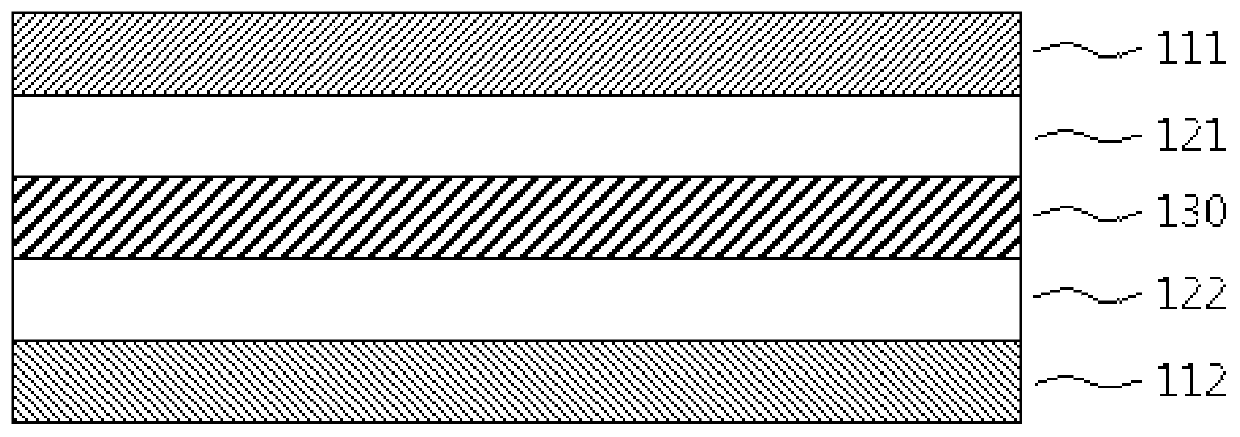

Printable Functional Hard Coating Film And Preparation Method Thereof

ActiveCN106883436AHigh hardnessImprove printing effectPolyurea/polyurethane coatingsPolymer resinHydrogen

The invention relates to a printable functional hard coating film and preparation method thereof, wherein the hard coating film has a structure that a base layer, a release layer and a hard coating layer are stacked in order. The release layer comprises silicone that is obtained by addition reaction between polydimethylsiloxane containing vinyl or hexenyl and hydrogen siloxanes; the hard coating layer comprises polymer resin that has a glass transition temperature of over 30 DEG C. The hard coating layer has a good hardness and print adhesion; the release layer can be peeled off from the hard coating layer easily, therefore, the release layer can be peeled off from the hard coating layer clean after printing or vapor depositing on the surface of the hard coating layer.

Owner:爱思开迈克沃解决方案有限公司

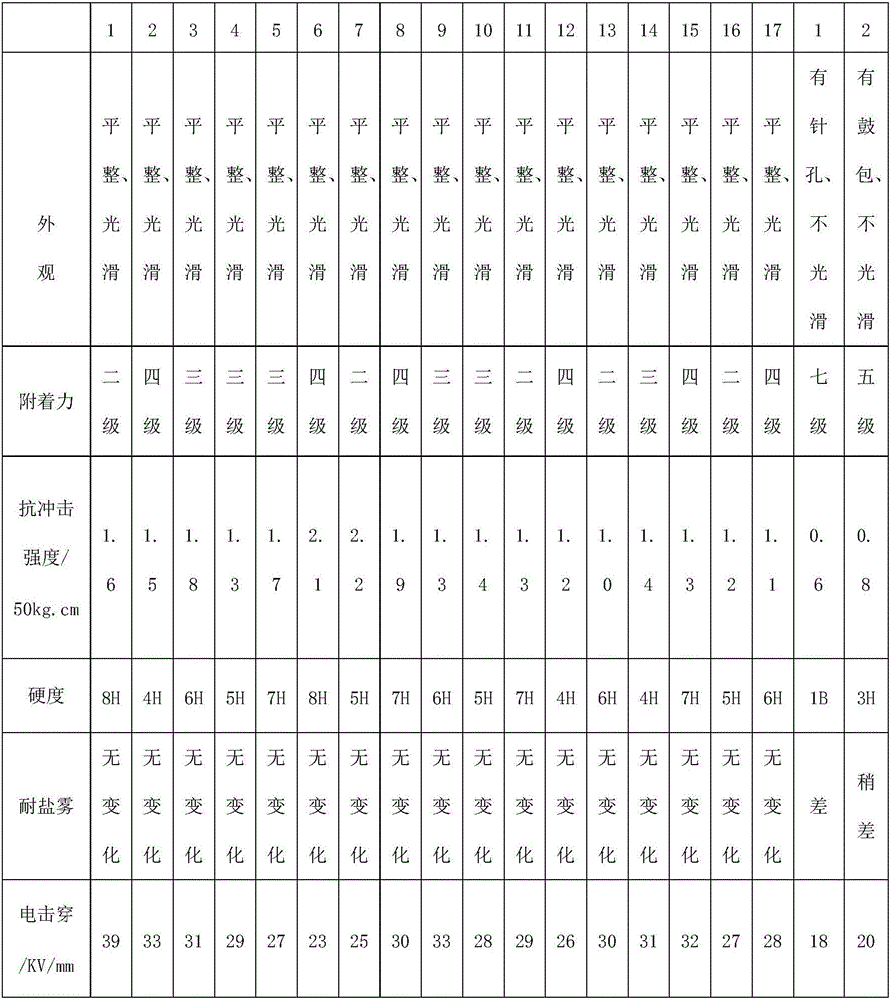

Ferrite core surface epoxy powder coating application process

InactiveCN106733566AEfficient removalIncrease roughnessPretreated surfacesPowdery paintsEpoxySodium bicarbonate

The invention relates to a ferrite core surface epoxy powder coating application process, comprising the steps of preparing modified epoxy powder coating, treating the surface of a ferrite core, thermally treating the surface, applying coating to the surface, thermally treating the surface, cooling, discharging, and detecting properties, wherein the modified epoxy powder coating is made by reaction of epoxy powder coating, a penetrant, nano metal powder, polyacrylate, and melamine resin, and a surface treating agent is made by reaction of sodium chloride, sodium bicarbonate, water and ethanol. The surface treating agent prepared herein is capable of excellently removing pollutants, such as oil, protein, fat, and dust; the modified epoxy powder coating has excellent properties, such as adhesion, leveling performance, and voltage breakdown resistance; the ferrite core surface epoxy powder coating application process designed herein provides adhesion of the epoxy powder coating to the surface of ferrite to be improved greatly, voltage breakdown resistance is achieved, and the defects such as pits, wrinkles, pinholes, bumps are effectively reduced.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

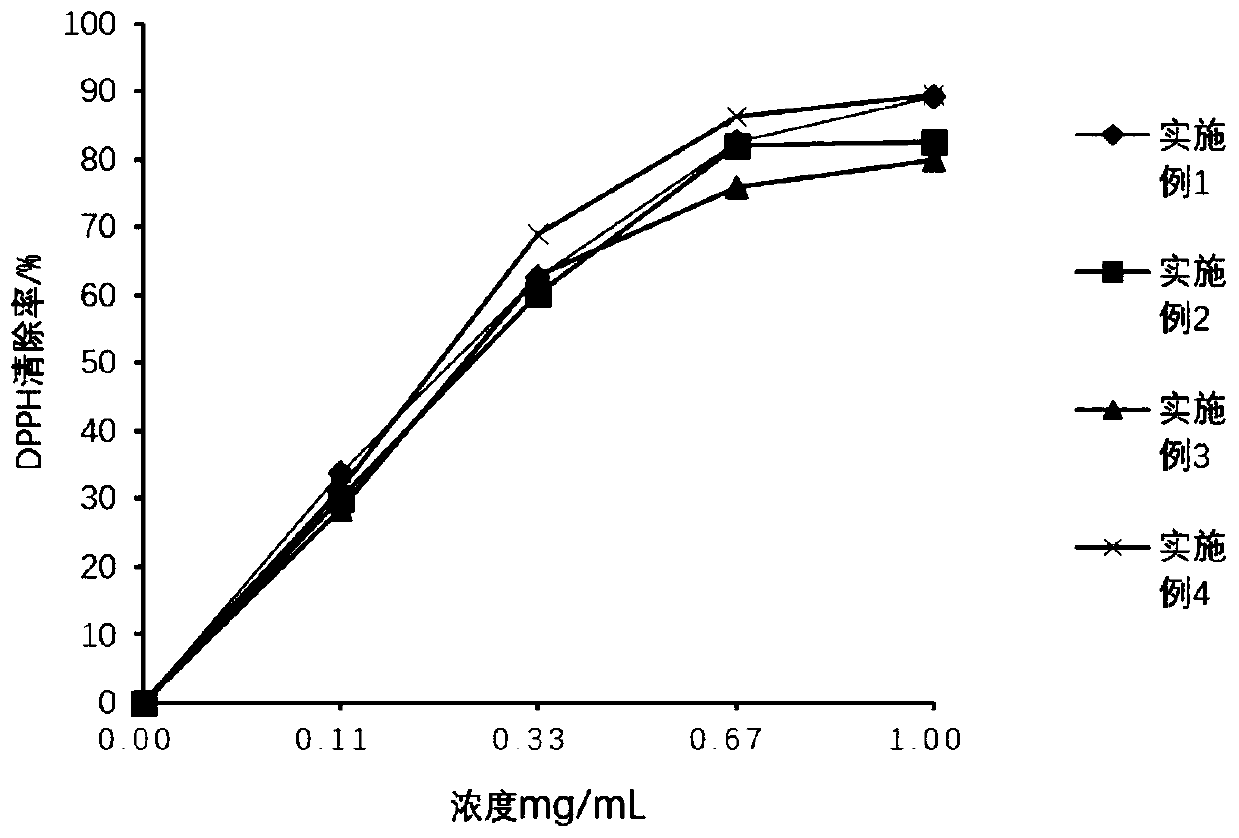

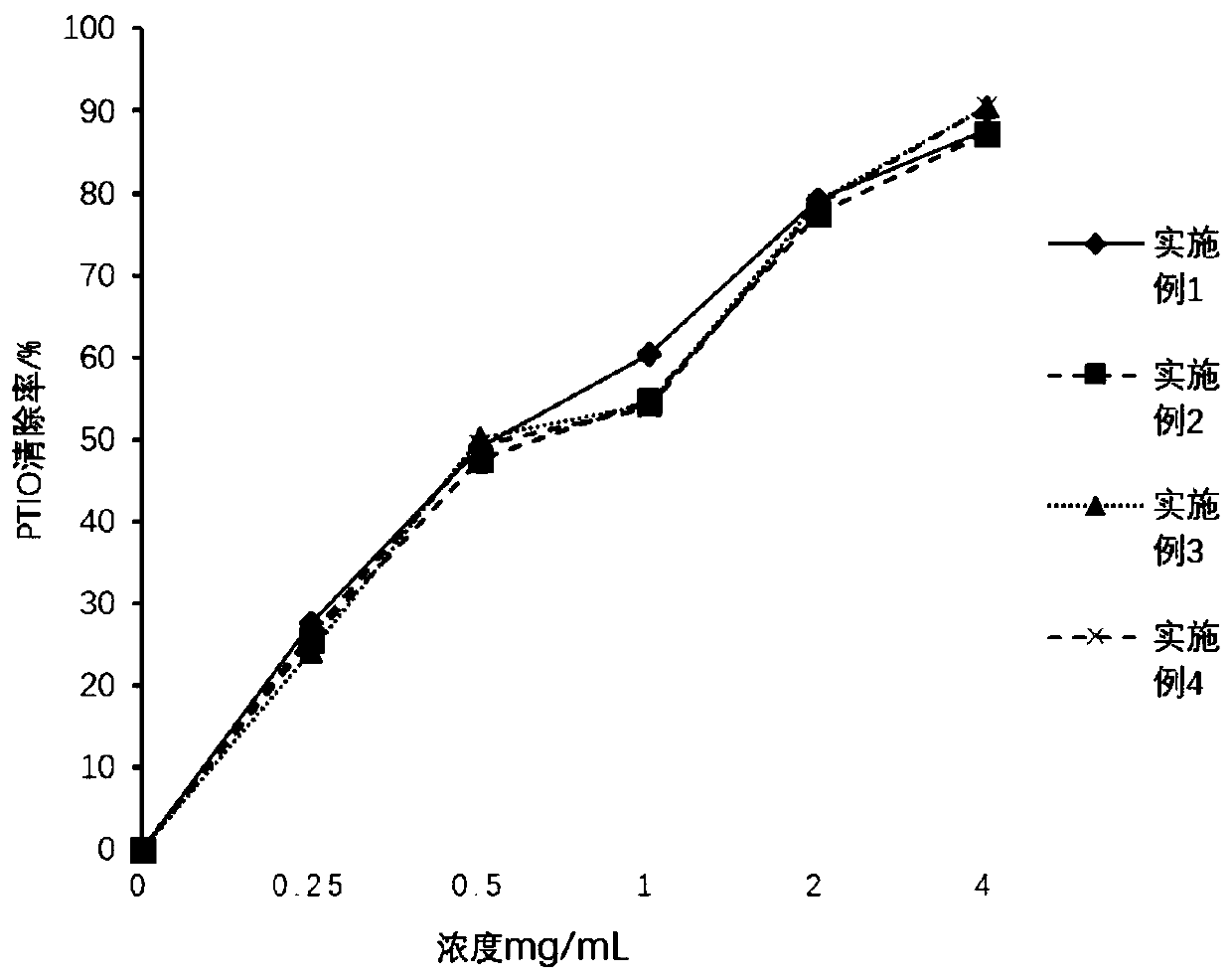

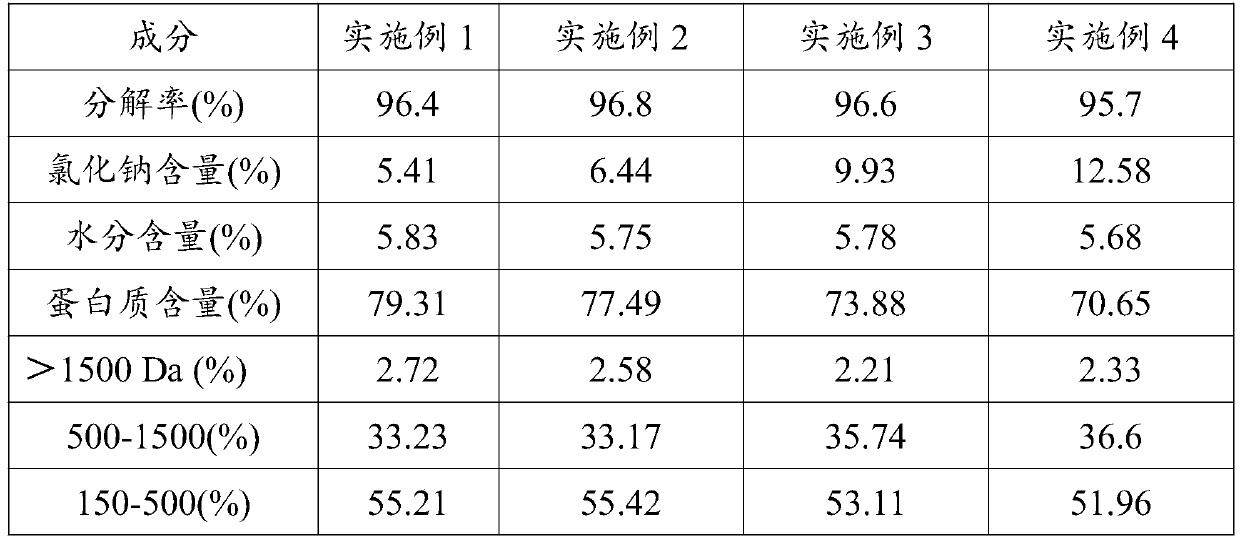

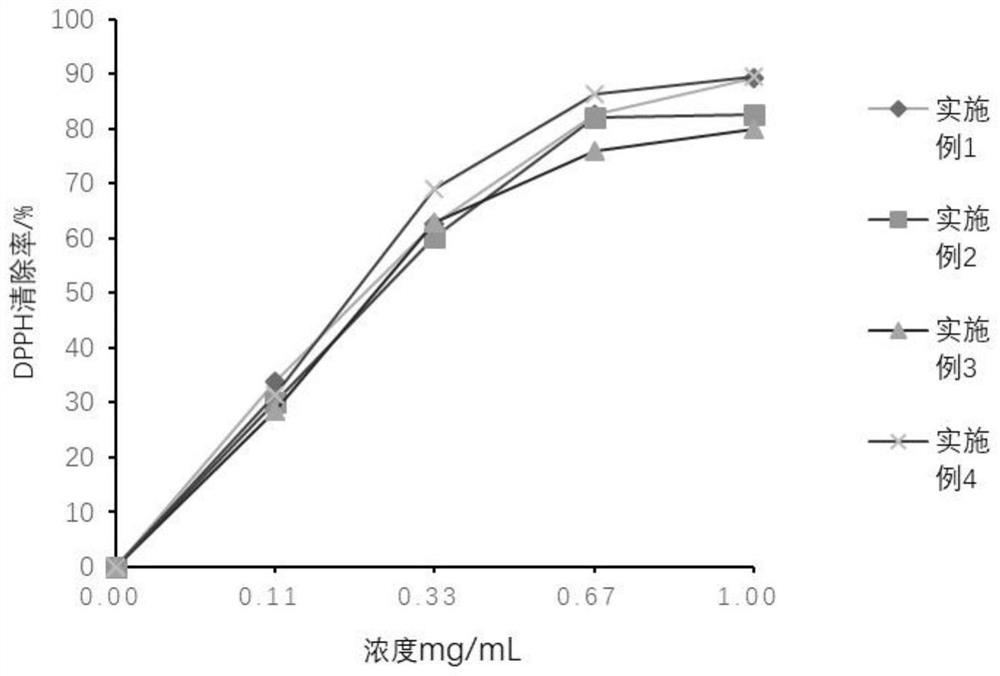

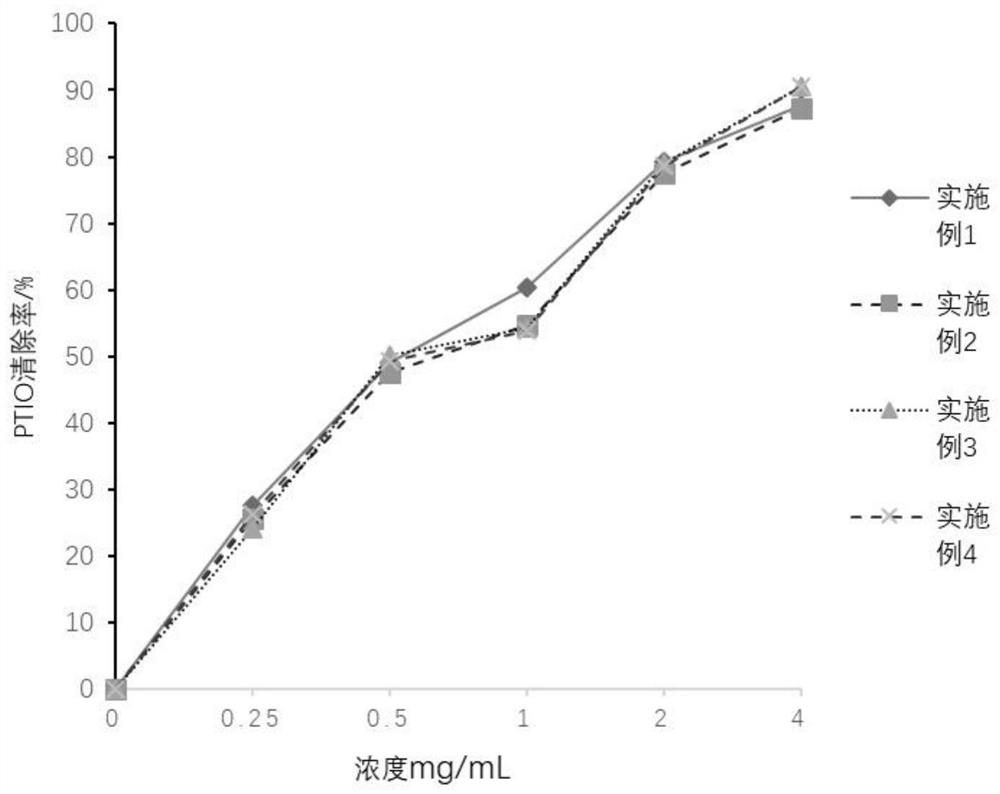

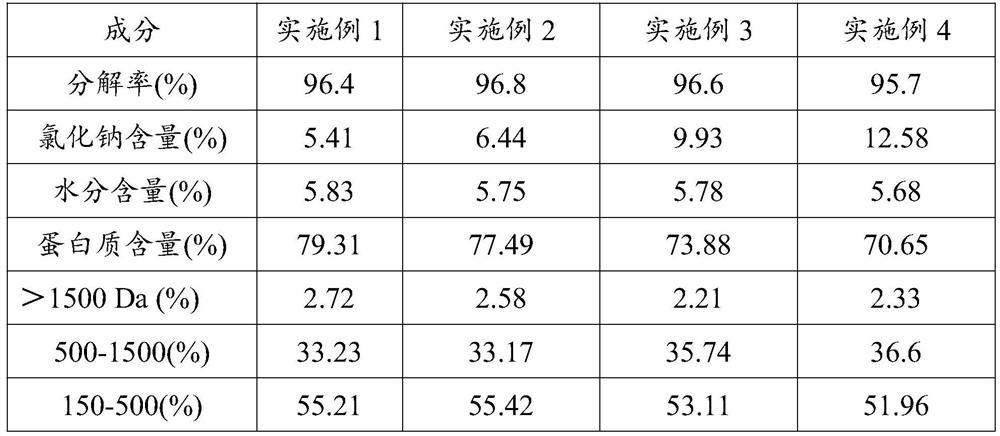

Method for preparing egg membrane element by subcritical method

ActiveCN111000790AImprove decomposition rateReduce manufacturing costCosmetic preparationsHair cosmeticsEggshell membraneSpray dried

The invention provides a method for preparing an egg membrane element by a subcritical method, and relates to the technical field of egg membrane element preparation. According to the invention, the egg membrane element is prepared by adopting the subcritical method, and the decomposition rate within 1h is up to 95% or above; and high-price enzymes are not needed, so that the production cost is reduced. According to the method disclosed by the invention, a solution obtained after eggshell membrane decomposition contains free amino acids and small molecule polypeptides, so that the content of the free amino acids and the small molecule polypeptides in the prepared egg membrane element is high, and the requirements of current cosmetics and health products on low molecular weight are met. According to the method, in a supernatant obtained through subcritical decomposition, sodium hydroxide is directly subjected to spray drying after being neutralized, and the desalting step is not needed.The method has the advantages of short procedure, low cost, easy preparation, conservation of energy and the like, and the obtained eggshell membrane polypeptide powder can be directly added into cosmetics and food after being sterilized.

Owner:正大食品(襄阳)有限公司

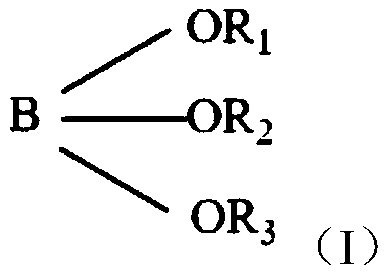

Inorganic nanometer material printing ink, preparation method and applications thereof

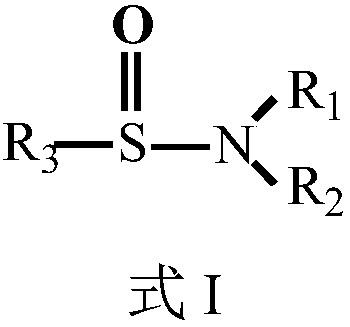

The invention provides an inorganic nanometer material printing ink, wherein the solvent in the inorganic nanometer material printing ink is an organic solvent, the inorganic nanometer material printing ink comprises at least an inorganic nanometer material and at least a sulfinamide-based organic solvent, the sulfinamide-based organic solvent has a structure represented by a structure general formula I, and in the formula I, R1 and R2 are independently selected from H, C1-20 aliphatic groups and C1-20 aromatic groups, R3 is selected from hydrocarbonyl or a hydrocarbonyl derivative, the hydrocarbonyl comprises aliphatic hydrocarbonyl and aromatic hydrocarbonyl, and the hydrocarbonyl derivative comprises an aliphatic hydrocarbonyl derivative and an aromatic hydrocarbonyl derivative.

Owner:TCL CORPORATION

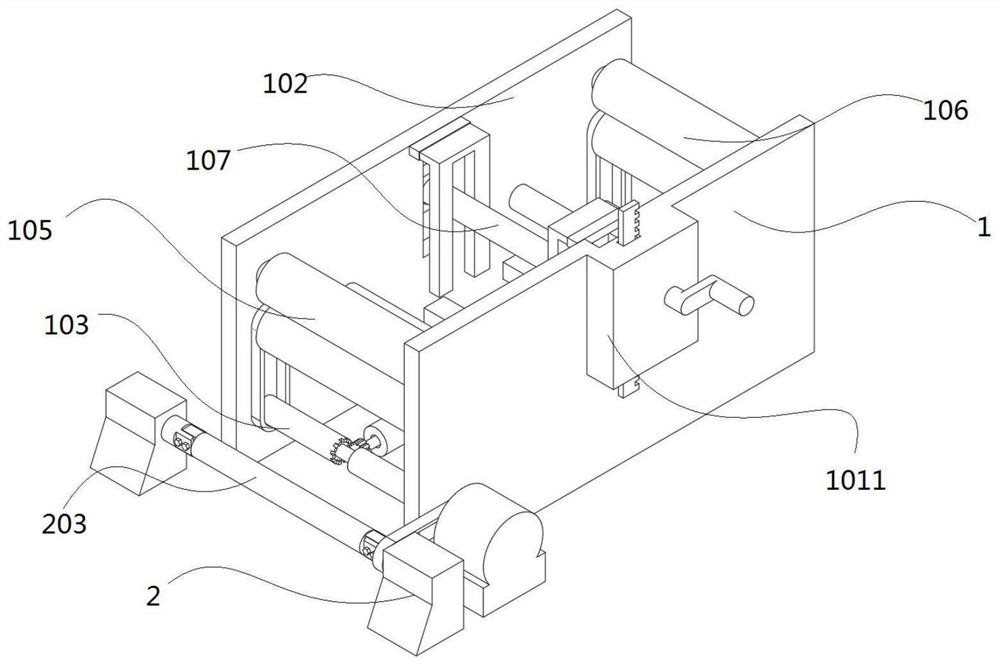

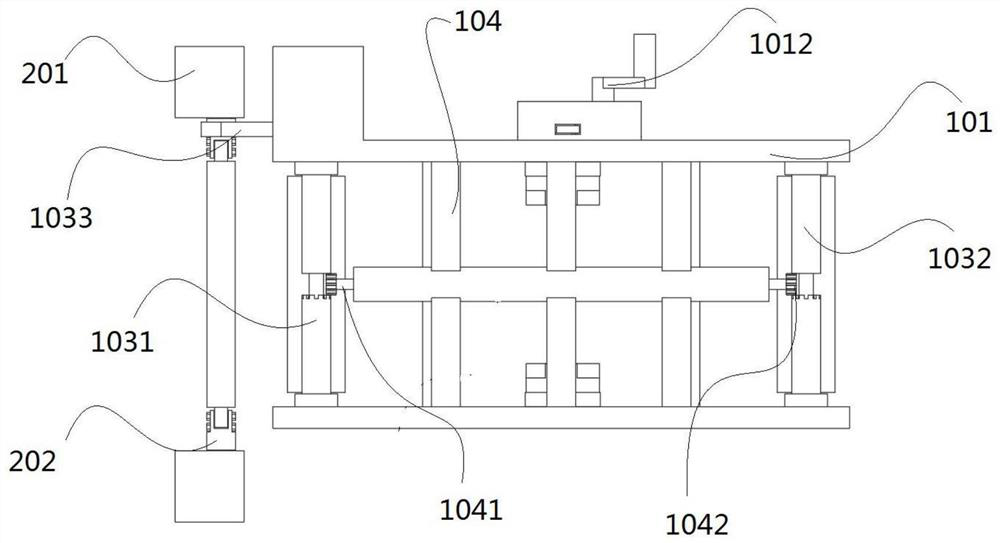

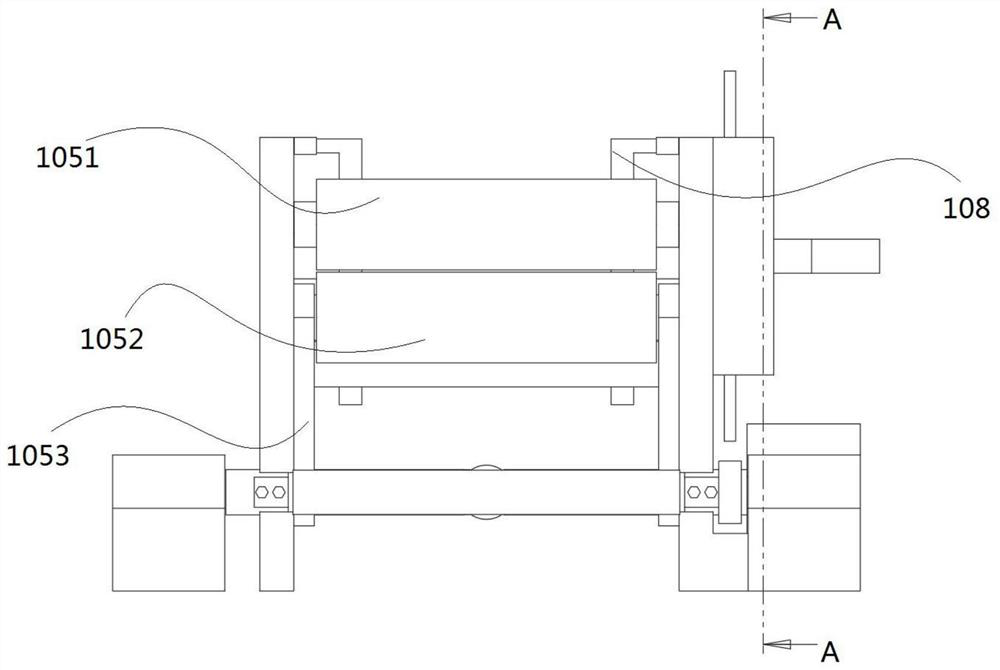

Adjustable winding machine for plastic film production

PendingCN112850288AAvoid affecting the winding efficiencyAdjust surface tensionWebs handlingWinding machineDrive shaft

The invention discloses an adjustable winding machine for plastic film production, and relates to the technical field of plastic film production equipment. The adjustable winding machine for plastic film production comprises an adjusting frame and a winding frame, wherein a driving roller set, a first auxiliary roller set, a second auxiliary roller set and an adjusting box are arranged in the adjusting frame. According to the adjustable winding machine for plastic film production, the adjusting box and an adjusting roller are arranged, the adjusting roller and other roller shafts can cooperate with each other to form an adjustable S-shaped roller set, the surface tension of a plastic film is adjusted by changing the position relation between the adjusting roller and the other roller shafts, and therefore wrinkles caused by loosening of the plastic film during winding of the winding machine are avoided, and the winding efficiency is influenced; and a driving belt, a first transmission belt, a second transmission belt and a transmission shaft are arranged, and therefore the driving roller set, the first auxiliary roller set, the second auxiliary roller set and the winding roller can cooperate in a transmission mode, the overall linkage effect is achieved, all the working roller sets in the interior of the winding machine can operate at the same time, the production efficiency is improved, and meanwhile, the space is saved.

Owner:浏阳市源友印务包装有限公司

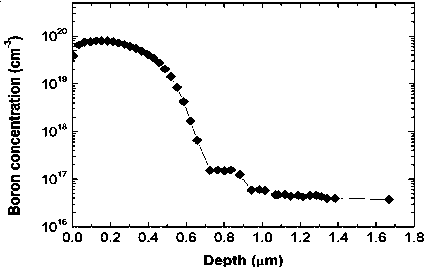

Boron-containing dopant slurry and application thereof

InactiveCN109860032AAvoid damageReduce heat consumptionDiffusion/dopingSemiconductor/solid-state device manufacturingThermal energyScreen printing

The invention provides boron-containing dopant slurry. The boron-containing dopant slurry is prepared from the following components in parts by weight: 5-70 parts of organic borate, 15-50 parts of polyol, 10-40 parts of dihydroxy ylamine and 0.1-2.5 parts of organic quaternary ammonium salt. The invention further provides a silicon wafer boron doping method. The silicon wafer boron doping method comprises the following steps that (1) the boron-containing dopant slurry is subjected to spraying or screen printing on the surface of a silicon wafer; (2) the silicon wafer treated in the step (1) isplaced into a diffusion furnace for boron diffusion, wherein the diffusion temperature is 700-850 DEG C. The boron-containing dopant slurry can realize low-temperature boron doping, thermal energy consumption can be obviously reduced, and damage to a crystal structure and electrical performance of a crystalline silicon substrate is reduced.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

Solvent type digital ink-jet printing dye sublimation ink and preparation method thereof

ActiveCN101709178BNot easy to aggregateGood storage stabilityInksDyeing processDisperse dyeTextile printer

The invention provides a solvent type digital ink-jet printing dye sublimation ink and a preparation method thereof. The ink comprises the following components in percentage by mass: 1 to 10 percent of disperse dye, 0.5 to 7 percent of resin and 20 to 95 percent of organic solvent. The preparation method comprises the following steps of: uniformly mixing 0.5 to 7 percent of resin and 20 to 95 percent of organic solvent at a normal temperature; adding 1 to 10 percent of disperse dye into the mixture; dissolving the disperse dye with a high-shear emulsifying machine at a rate of between 400 and1,000 rpm for 0.5 to 5h; and filtering the mixture with a filter of which the aperture is 0.2 to 2 mu m to obtain the solvent type digital ink-jet printing thermal-sublimation ink. The ink is not influenced by the temperature change of a printing environment, and has the advantages of good injection stability and storage stability, simple preparation process and low energy consumption.

Owner:上海英威喷墨科技有限公司

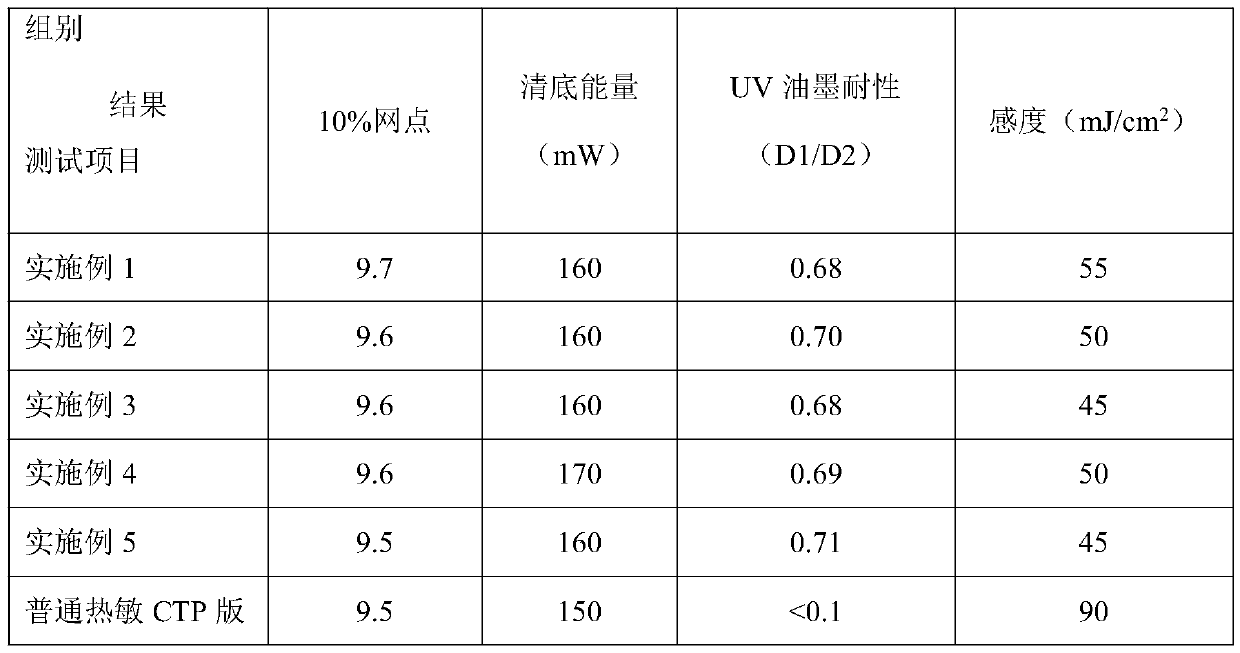

Temperature-sensitive CTP type imaging coating

InactiveCN110187605AImprove solubilityIncrease developer solubilityPhotosensitive materials for photomechanical apparatusSolubilityHeat sensitive

The invention discloses a temperature-sensitive CTP type imaging coating having good stability and coating property. The temperature-sensitive CTP type imaging coating is characterized in that the coating is composed of following components, including solvent resistant resin, alkali soluble resin, film forming resin, solubilizer, added resin, solubility-inhibiting and solubility-promoting resin, infrared absorbing dye and dye, wherein the alkali soluble resin is modified resin obtained by copolymerizing alkali soluble structural monomer, acrylamide structural monomer, and / or sulfonamide structural monomer, and the solubility-inhibiting and solubility-promoting resin is phenol etherified resin. The coating is advantaged in that CTP plates prepared by the above formula have better printing durability and solvent resistance and have relatively low sensitivity.

Owner:海宁市速美印刷科技股份有限公司

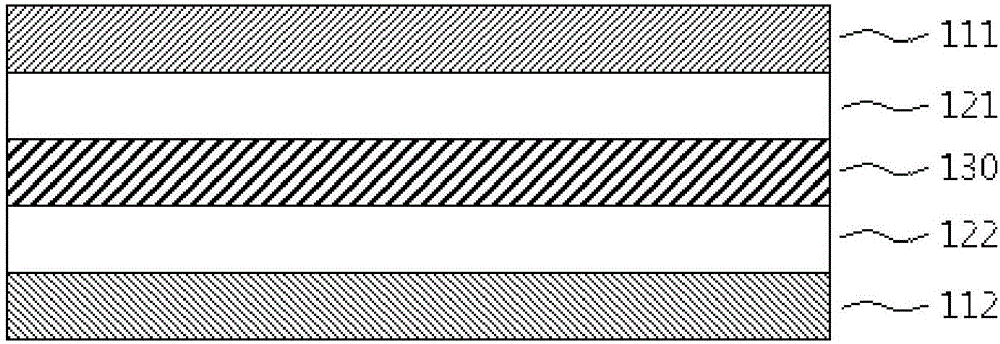

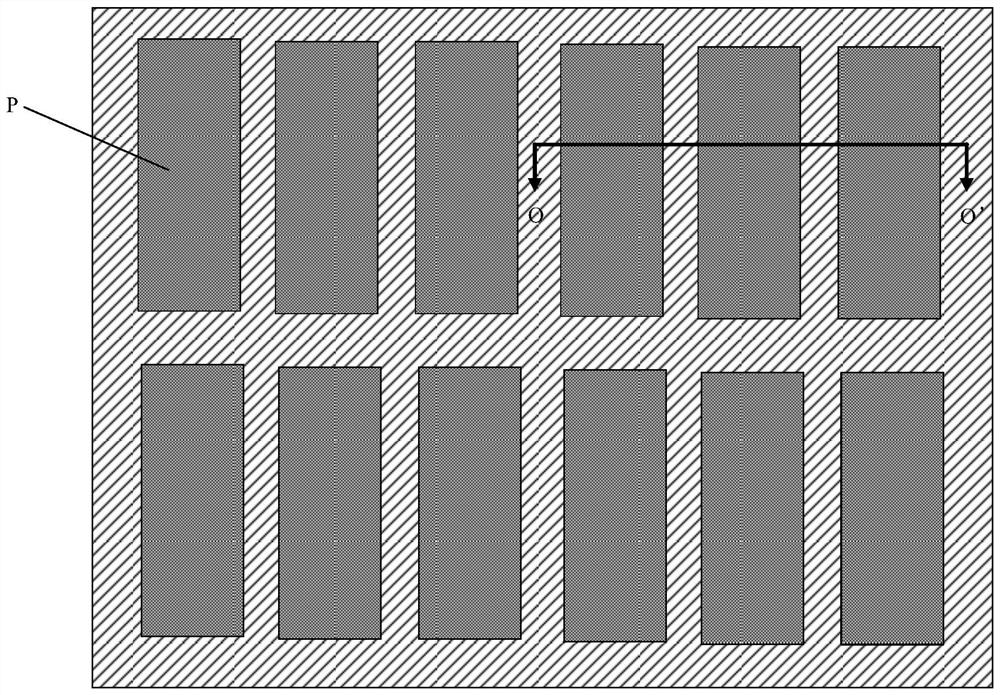

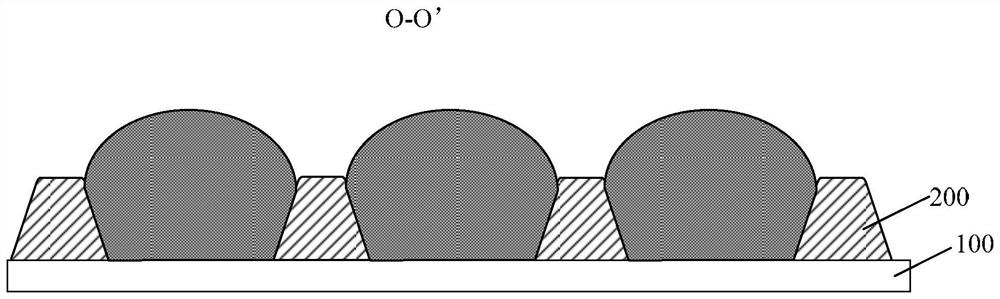

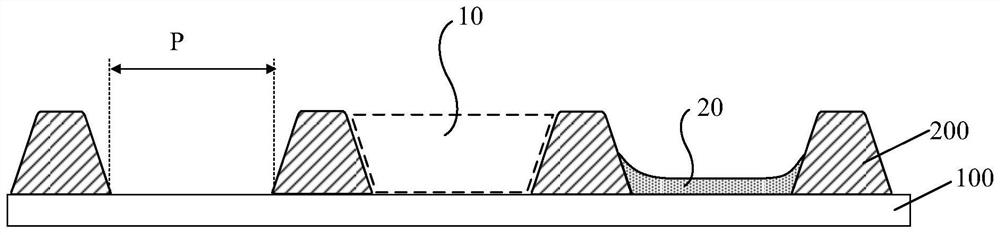

An array substrate, its preparation method, and a display device

ActiveCN108054184BAdjust surface tensionAdjust the force distributionSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

Embodiments of the present invention provide an array substrate, a preparation method, and a display device, which relate to the field of display technology and can improve the uniformity of a light-emitting functional layer. The array substrate includes a pixel definition layer arranged on the base substrate to define the sub-pixel light-emitting area, the pixel-definition layer is hollowed out at the position of the sub-pixel light-emitting area, and a light-emitting functional layer is arranged in the hollow; the pixel definition layer is located at the position of the sub-pixel light-emitting area Cutout sides feature raised features.

Owner:BOE TECH GRP CO LTD

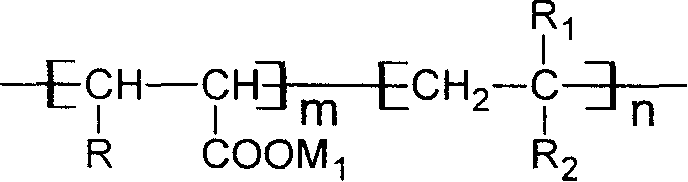

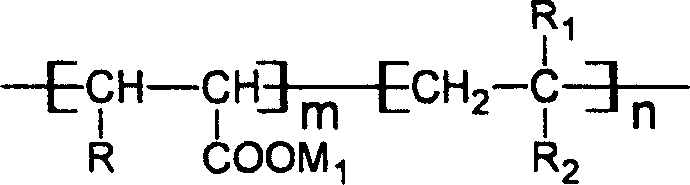

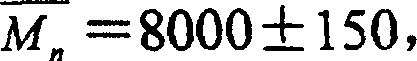

Nano dye ink for ink jet printing and preparation method thereof

InactiveCN100335572CGuaranteed long-term stabilityAdjust surface tensionInksPrintingPrinting inkWater soluble

The present invention relates to a nano pigment spray-printing ink for computer ink jet printer and colour spray plotter. Said invention adopts a high-molecular dispersing agent to modify pigment surface so as to make the pigment be stably dispersed in water medium, and adds several water-soluble cosolvents to prepare a set of colour inks, including red, yellow, blue and black four inks.

Owner:JIANGNAN UNIV

Printable functional hard coating film and preparation method thereof

ActiveCN106883436BHigh hardnessImprove printing effectPolyurea/polyurethane coatingsPolymer scienceGlass transition

The invention relates to a printable functional hard coating film and preparation method thereof, wherein the hard coating film has a structure that a base layer, a release layer and a hard coating layer are stacked in order. The release layer comprises silicone that is obtained by addition reaction between polydimethylsiloxane containing vinyl or hexenyl and hydrogen siloxanes; the hard coating layer comprises polymer resin that has a glass transition temperature of over 30 DEG C. The hard coating layer has a good hardness and print adhesion; the release layer can be peeled off from the hard coating layer easily, therefore, the release layer can be peeled off from the hard coating layer clean after printing or vapor depositing on the surface of the hard coating layer.

Owner:爱思开迈克沃解决方案有限公司

Formula of face sparkling emulsion

InactiveCN107753316AAdjust surface tensionThree-dimensional makeupCosmetic preparationsToilet preparationsEmulsionNose bridge

The invention discloses and provides a formula of face sparkling emulsion which enables skin to be pearly and sparkling, brightens positions such as nose bridge, inferior of brow ridges and upward sides of apple zones, required to be highlighted, of face, enables face makeup to be stereoscopic, beautiful and stable and is a high-pearly-lustre system. The formula which is disclosed and provided bythe invention is applicable to the technical field of preparation of cosmetics.

Owner:中山市美源化妆品有限公司

A kind of method that subcritical method prepares egg membrane protein

ActiveCN111000790BImprove decomposition rateReduce manufacturing costCosmetic preparationsHair cosmeticsBiotechnologyEggshell membrane

The present invention provides a method for preparing egg-membrane by subcritical method, and relates to the technical field of egg-membrane preparation. The invention adopts the subcritical method to prepare the egg membrane, and the decomposition rate within 1 hour is as high as more than 95%; and high-priced enzymes are not needed, and the production cost is reduced. In the method of the present invention, the solution after decomposing the eggshell membrane contains free amino acids and small molecular polypeptides, so that the free amino acids and small molecular polypeptides in the prepared egg membrane protein are high in content, which satisfies the requirements of current cosmetics and health care products for low molecular weight . In the method of the present invention, in the supernatant liquid obtained by subcritical decomposition, the sodium hydroxide is directly spray-dried after neutralization, no desalting step is required, and the method has the advantages of short process, low cost, simple preparation, energy saving and the like, and the obtained eggshell Membrane polypeptide powder can be directly added to cosmetics and food after sterilization.

Owner:正大食品(襄阳)有限公司

Composite foaming agent for urea-formaldehyde resin, preparing method and application thereof

InactiveCN101586014BImprove securityAdjust surface tensionNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesFoaming agentNational standard

The present invention discloses a composite foaming agent for urea-formaldehyde resin, a preparing method and an application thereof. The composite foaming agent of the invention is composed of a foaming agent, a foam stabilizer and a dispersing agent. After the composite foaming agent is added into the urea-formaldehyde resin additive, the volume of the urea-formaldehyde resin can be increased for 2-3 times for forming the fine, uniform and long-lasting foamed urea-formaldehyde resin, effectively regulating the surface tension of the glue solution, reducing the conglobation phenomenon of flour, increasing the fluidity of the urea-formaldehyde resin, settling the adverse phenomena of glue bleeding, glue leakage, non-homogeneous adhesive layer, etc. which commonly exist in the prior urea-formaldehyde resin adhesive, so that the urea-formaldehyde resin on the plate blank of the veneer board has excellent homogeneity and the bleeding balancing is kept and the total usage of flour and theurea-formaldehyde resin after adhesive mixing is reduced for 10-30%. Additionally, the composite foaming agent of the invention has the advantages of excellent safety, no adverse effect in the using process and capability for effectively reducing the release amount of the formaldehyde of the artificial board. Furthermore the mechanical properties of the prepared artificial board can equally obtainthe requirement of the national standard.

Owner:EVERFIRST WISEFUND TECH BEIJING

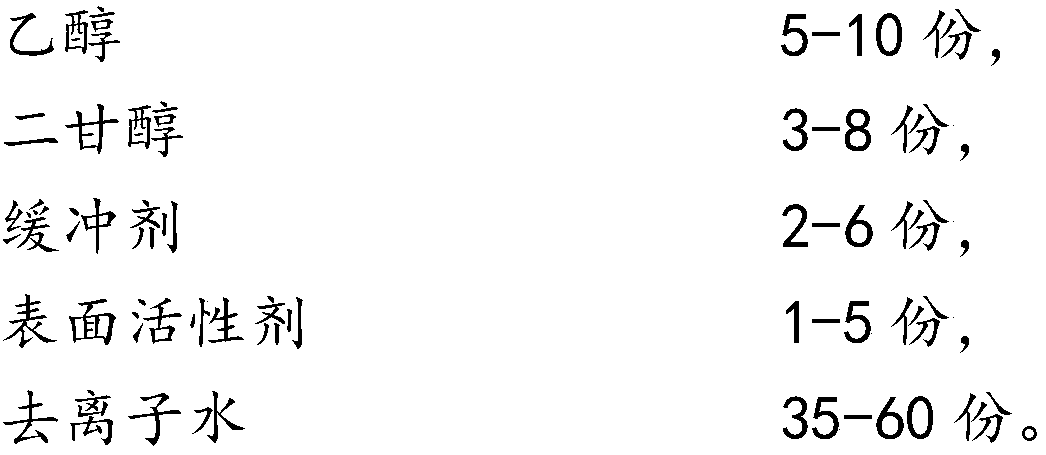

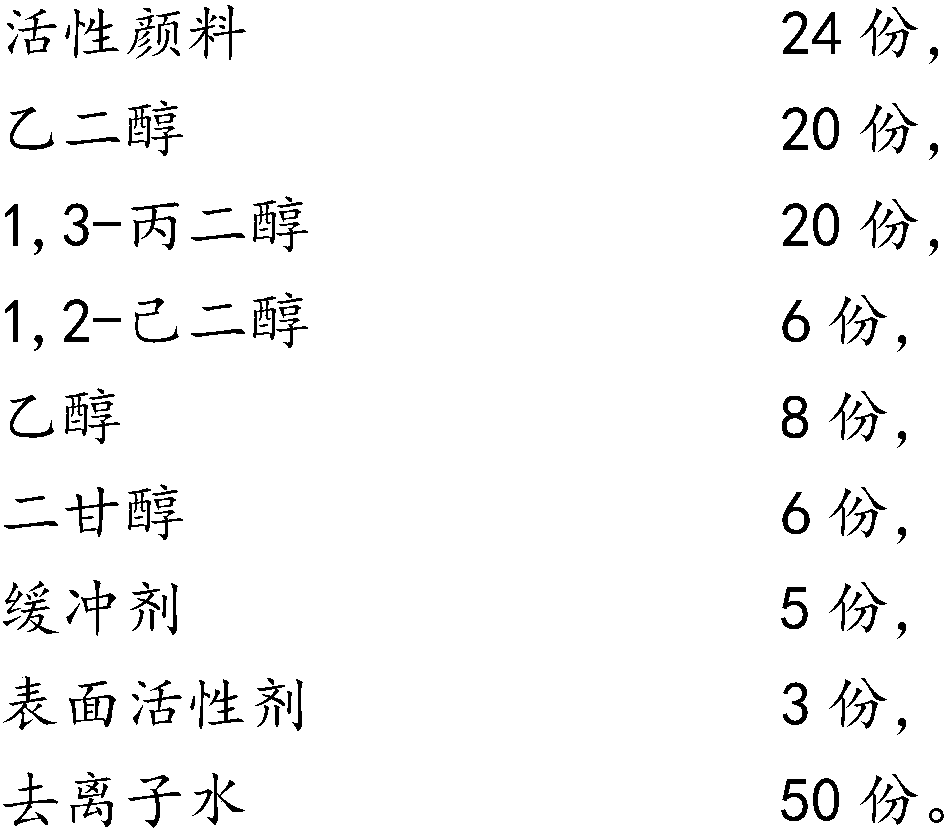

Dihydric alcohol type active dye ink

The invention discloses dihydric alcohol type active dye ink. The active dye ink comprises the raw materials of active pigments, ethylene glycol, 1,3-propanediol, 1,2-hexanediol ethanol, diethylene glycol, a buffer agent, a surfactant, and deionized water. The active pigments in the active dye ink are prepared by mixing glycol and 1,3-propylene glycol in a proportion of 1 to 1, so that the durability of the dye ink can be improved, and the dye ink has good moisture preserving property, K / S value and color fixation rate; meanwhile, by adding 1,3-hexanediol, on one hand, the stability of the inkcan be improved by virtue of 1,3-hexanediol as an ink solvent, the surface tension of the dye ink can be adjusted by virtue of 1,3-hexanediol as a surface tension regulator, the viscosity of the inkcan be adjusted, and the decrease of the color fixation rate of the ink in the storage process can be improved; and by adding diethylene glycol, a hydrogen bond generated by diethylene glycol and water is relatively strong and is unlikely to be broken, so that the layering of the active dye link can be avoided.

Owner:QINGDAO UNIV

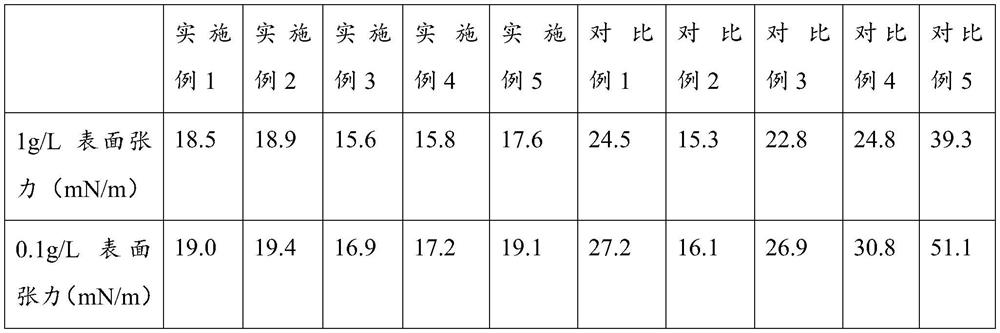

Synergist and application thereof

PendingCN114642202AImprove efficacyIncrease profitBiocideFungicidesPESTICIDE ADJUVANTSPolythylene glycol

The invention belongs to the technical field of pesticide adjuvants, and particularly relates to a synergist and application thereof. The effective components of the synergist comprise perfluorononyl polyethylene glycol ether and isomeric alcohol polyoxyethylene polyoxypropylene ether, the perfluorononyl polyethylene glycol ether comprises C9F17O (CH2CH2O) nH (perfluorononyl polyethylene glycol monoether) and C9F17O (CH2CH2O) nC9F17 (perfluorononyl polyethylene glycol diether), and n is in a range of 6 to 30; the number of PO in the isomeric alcohol polyoxyethylene polyoxypropylene ether is not more than 7. According to the synergist, the pesticide can have relatively balanced diffusivity and permeability through the matching effect of the effective components, the residual quantity of the pesticide on leaf surfaces can be reduced, the pesticide effect of the pesticide can be enhanced, the pesticide utilization rate can be increased, the synergist can enable pesticide liquid to be diffused to the whole leaf surfaces, permeate into plants and be absorbed by the plants, the pesticide damage is small, and the pesticide effect is good. The pesticide utilization rate is high and the pesticide effect is good.

Owner:JIAHUA CHEM TECH DEV SHANGHAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com