Adjustable winding machine for plastic film production

A plastic film, adjustable technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problem of inconveniently changing the width of the winding action, and achieve the effect of saving space and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

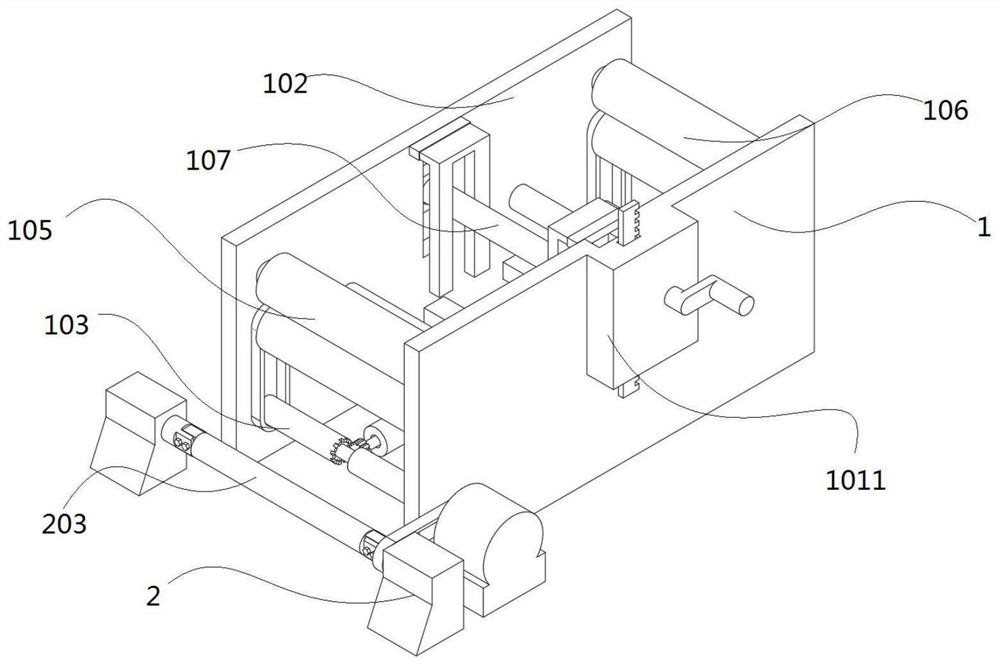

[0040] see Figure 1-6 As shown, the present embodiment is a working process of a winder for adjustable plastic film production:

[0041] The model of the winding motor involved in the present invention is the MS8034 three-phase asynchronous motor;

[0042] When using the winding machine of the present invention, the plastic film produced first enters the winding machine through the second auxiliary roller group 106, and then passes through the second driving roller 1032, the connecting roller 109, the regulating roller 107, the connecting roller 109, the second An auxiliary roller set 105 and the first driving roller 1031 are extended to the outside of the winder through the first driving roller 1031, connected with the winding roller 203, and the plastic film is wound under the operation of the winding motor.

Embodiment 2

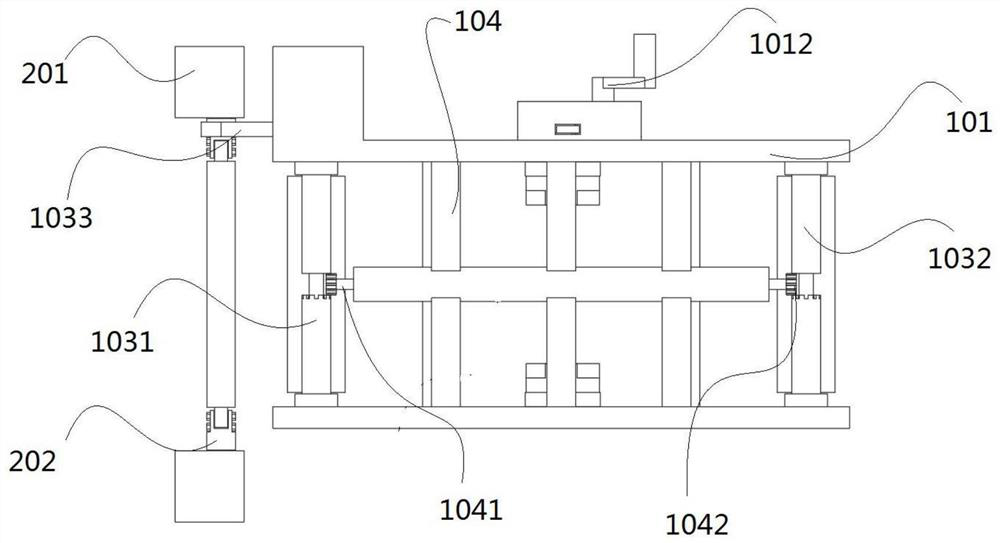

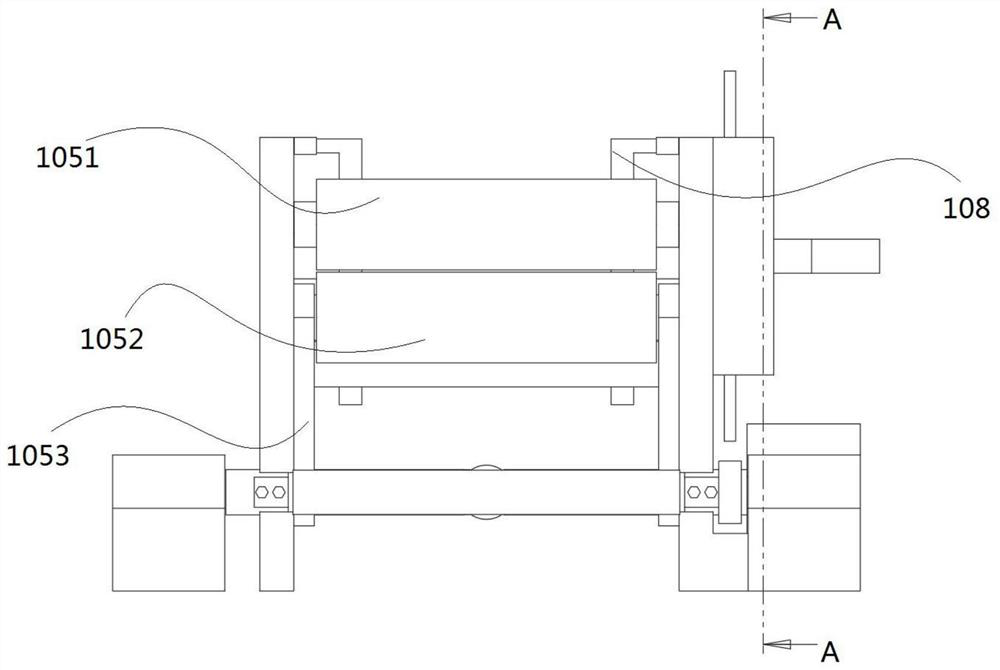

[0044] see Figure 1-6 As shown, the present embodiment is the operating principle of a winder for adjustable plastic film production:

[0045] When the winder of the present invention is working, at first, the positional relationship between each roller shaft in the winder constitutes an "S" shape roller group, and then after passing through the plastic film, by shaking the rocker 1012, the second gear 1013 Engage with the rack 1073, and then change the height of the adjusting roller 107, so that the positional relationship between it and other roller shafts is changed, further changing the tension on the surface of the plastic film, and avoiding wrinkles on the surface caused by the loosening of the plastic film; at the same time , when the width of the plastic film changes, by adjusting the telescopic length of the limit card, it can adapt to and limit the width of the winder when it is rolled, so as to avoid unstable winding and produce defective products; in addition, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com