Polyester fabric trimming and winding device

A winding device, technology of polyester cloth, applied in the direction of winding strips, transportation and packaging, textiles and papermaking, etc., can solve the problems of cloth scattered everywhere, waste of site space, dropped lines, etc., to facilitate collection and sorting, prevent The effect of winding the cloth guide roller to prevent the thread from falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

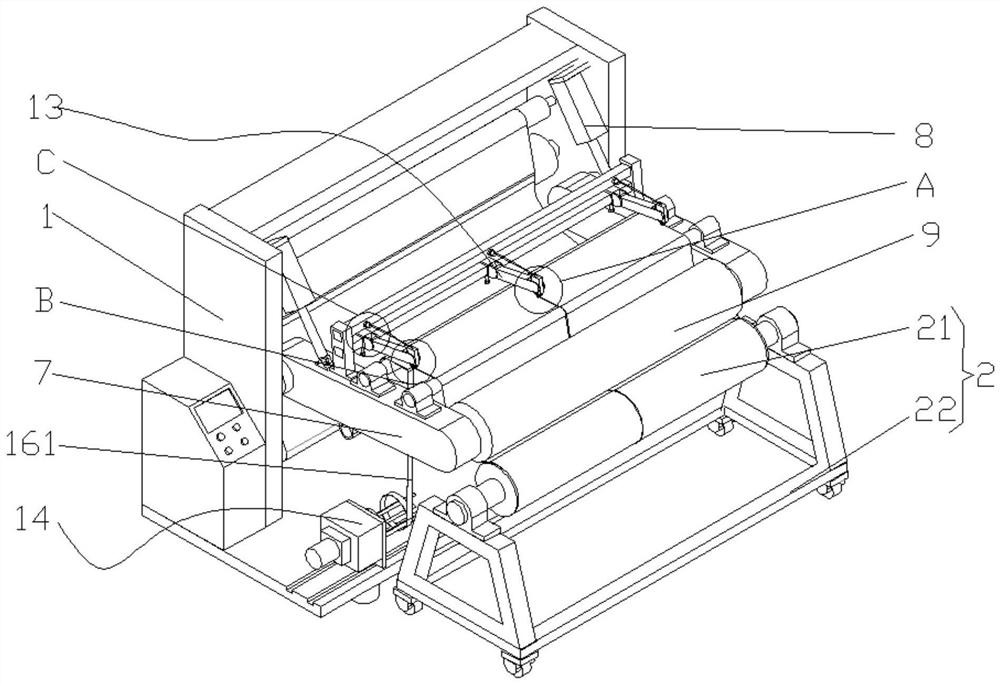

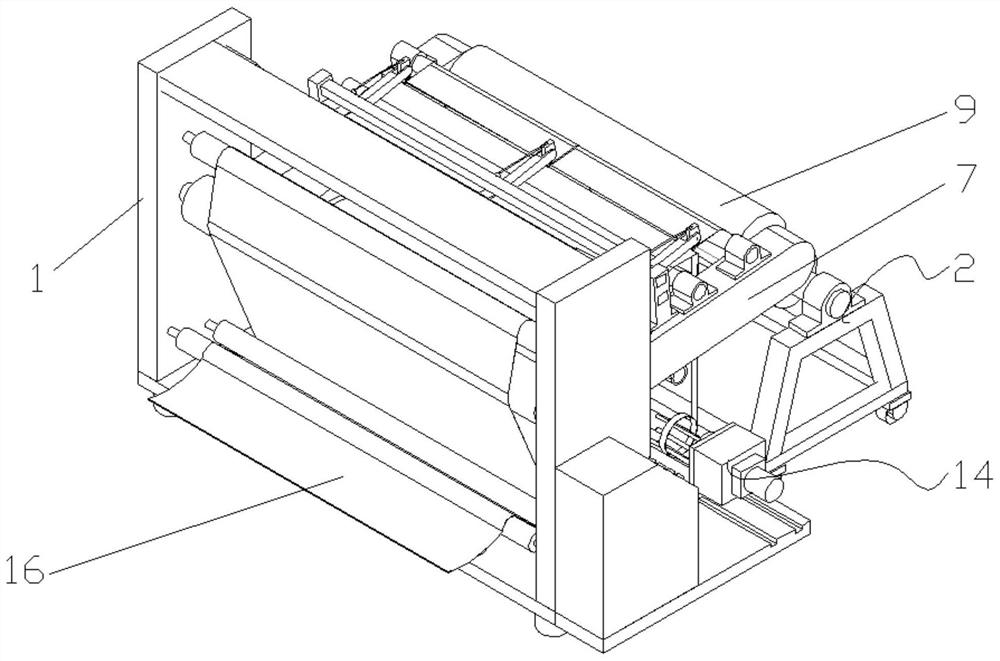

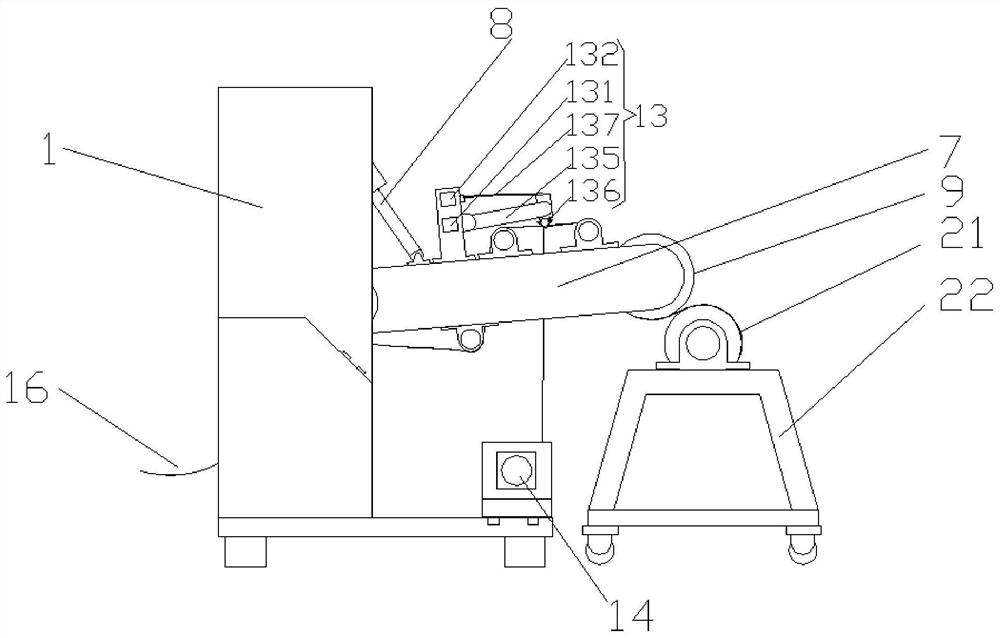

[0031] The embodiment of the present invention provides a polyester fabric cutting device, such as Figure 1-12 As shown, the rack 1, the cannula mechanism 2, the coil mechanism 2 includes a roller 21 and a roll bracket 22, a roll bracket 22, which is convenient for movement and transport of the coil mechanism 2.

[0032] like Figure 5 As shown, the rack 1 is pivotally attached to the welding roller one 3, the guide roller two 4, the guide roller three 5, the guide roller 4 6, and the rack 1 is also hinged there in a set of residential arms 7, and the rack 1 is sequentially pivoted. The exhibition arm 7 is lifted down by a set of cylinders 8, and the cylinder 8 cylinder is fixed to the bracket 1, and the cylinder end of the cylinder 8 is hinged on the exhibition arm 7, and the exhibition arm 7 is hinged on the rack 1, and the other end center The drive coiled roller 9 is pivotally connected, and the driven coil roller 9 and the slave roller 21 of the collecting mechanism 2 are pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com