A winding machine for high voltage cable recycling

A high-voltage cable and winder technology, applied in the field of winders, can solve problems such as affecting the use of high-voltage cables, hurting people's hands, and easy to sore hands.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

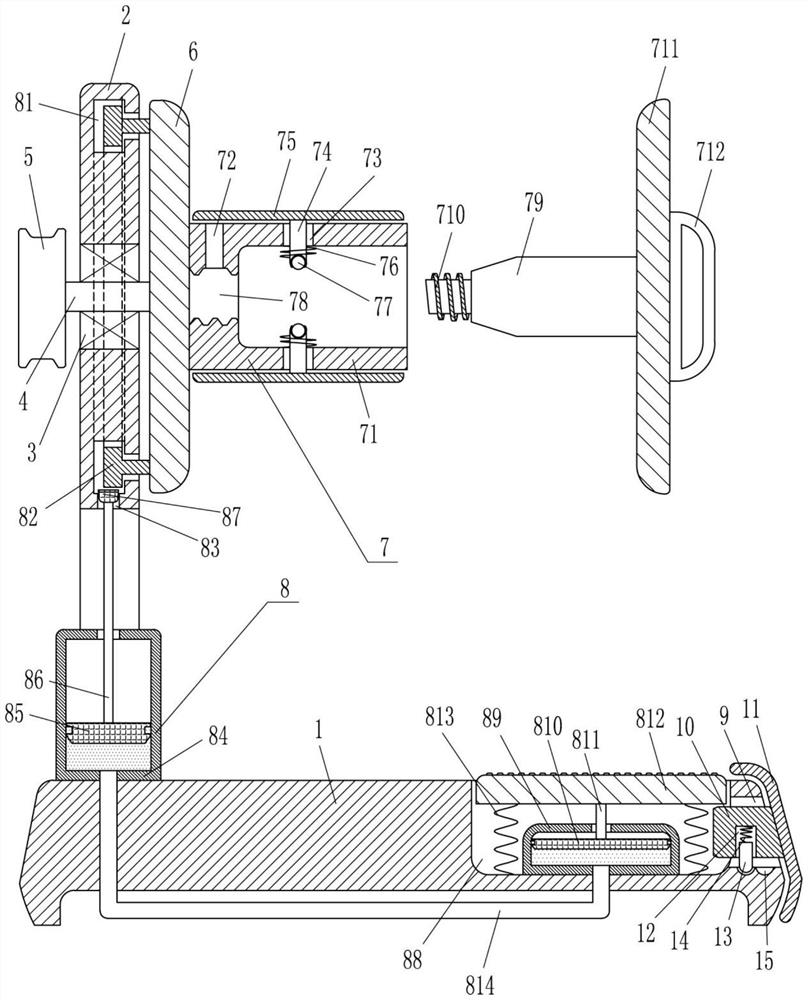

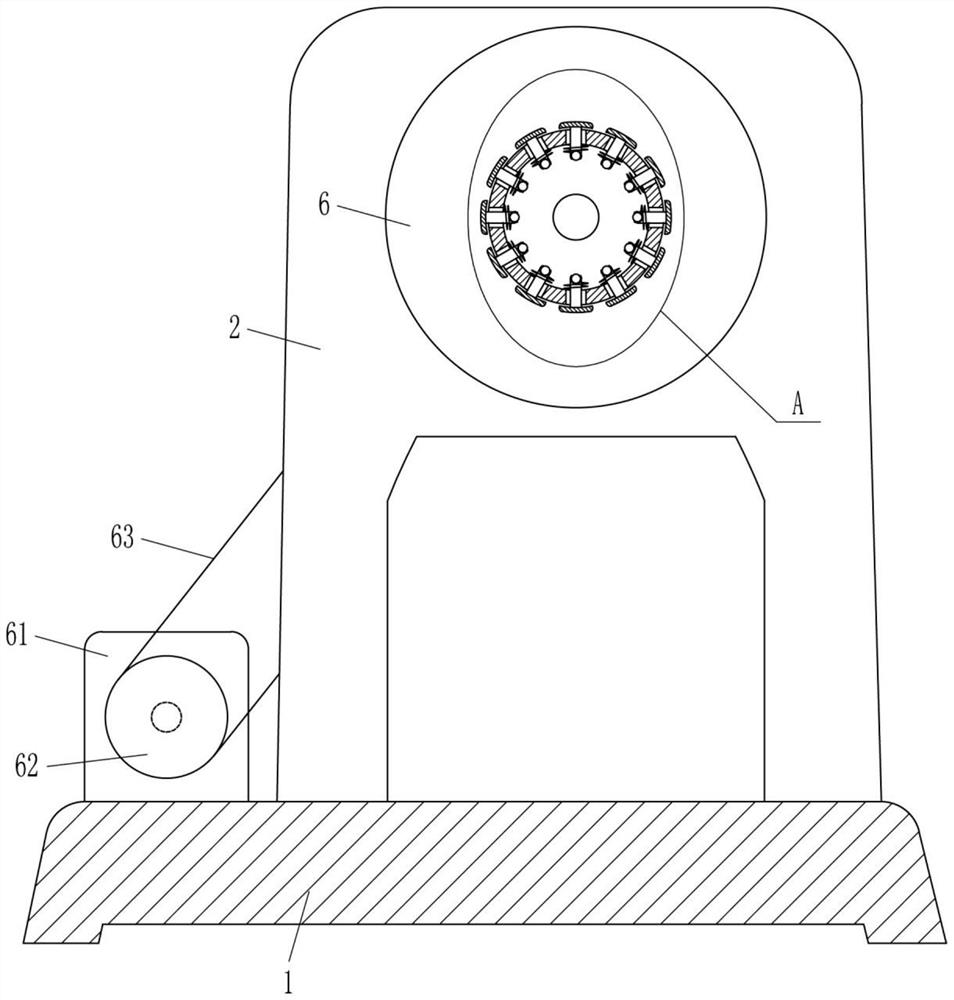

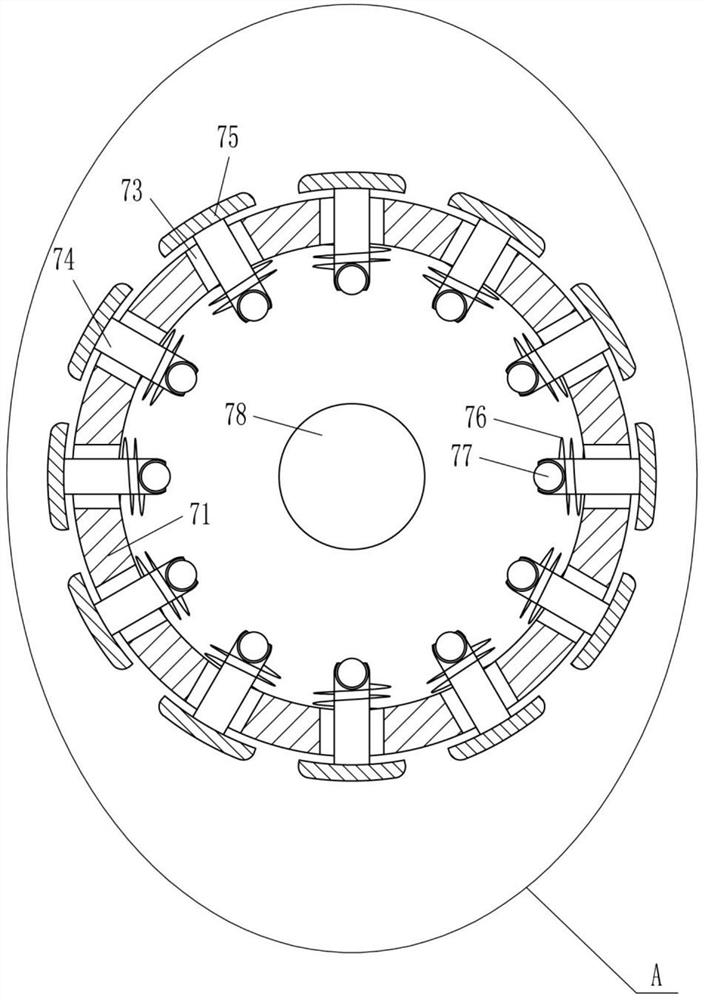

[0015] A winding machine for recycling high-voltage cables, such as Figure 1-3 As shown, it includes a base 1, an n-type support plate 2, a bearing seat 3, a rotating shaft 4, a first pulley 5, a first disc 6, a driving motor 61, a second pulley 62, a flat belt 63 and a fixing device 7, and the base 1. An n-type support plate 2 is fixedly connected to the left side of the top, and the base 1 is connected to the n-type support plate 2 by welding. A bearing seat 3 is embedded in the middle of the upper part of the n-type support plate 2. The bearing seat 3 is equipped with There is a rotating shaft 4, and the right end of the rotating shaft 4 is fixedly connected with the first disc 6, the rotating shaft 4 is connected with the first disc 6 by welding, and the center of the right side of the first disc 6 is provided with a high-voltage cable roll-up The fixing device 7, the left end of the rotating shaft 4 is fixedly connected with the first pulley 5, the rotating shaft 4 is co...

Embodiment 2

[0017] A winding machine for recycling high-voltage cables, such as Figure 1-3 As shown, it includes a base 1, an n-type support plate 2, a bearing seat 3, a rotating shaft 4, a first pulley 5, a first disc 6, a driving motor 61, a second pulley 62, a flat belt 63 and a fixing device 7, and the base 1. An n-type support plate 2 is fixedly connected to the left side of the top, and a bearing seat 3 is fixedly connected to the middle of the upper part of the n-type support plate 2. A rotating shaft 4 is arranged inside the bearing seat 3, and a first disc 6 is fixedly connected to the right end of the rotating shaft 4. , the center of the right side of the first disk 6 is provided with a fixing device 7 that can roll up the high-voltage cable, the left end of the rotating shaft 4 is fixedly connected with the first pulley 5, and the left front part of the top of the base 1 is equipped with a driving motor 61. The output shaft of 61 is connected with a second pulley 62 through a...

Embodiment 3

[0020] A winding machine for recycling high-voltage cables, such as Figure 1-3 As shown, it includes a base 1, an n-type support plate 2, a bearing seat 3, a rotating shaft 4, a first pulley 5, a first disc 6, a driving motor 61, a second pulley 62, a flat belt 63 and a fixing device 7, and the base 1. An n-type support plate 2 is fixedly connected to the left side of the top, and a bearing seat 3 is fixedly connected to the middle of the upper part of the n-type support plate 2. A rotating shaft 4 is arranged inside the bearing seat 3, and a first disc 6 is fixedly connected to the right end of the rotating shaft 4. , the center of the right side of the first disk 6 is provided with a fixing device 7 that can roll up the high-voltage cable, the left end of the rotating shaft 4 is fixedly connected with the first pulley 5, and the left front part of the top of the base 1 is equipped with a driving motor 61. The output shaft of 61 is connected with a second pulley 62 through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com