Printable functional hard coating film and preparation method thereof

A technology of hard coating and hard coating, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of hard coating residue, high peeling force, difficult to control peeling force, etc., and achieve excellent hardness and printability , easy peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

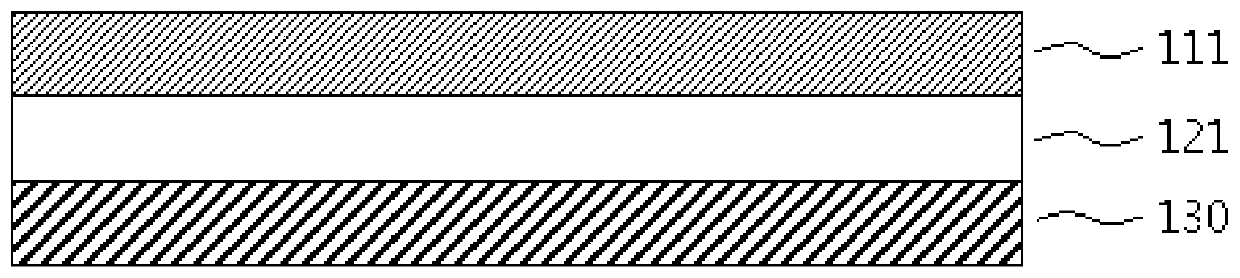

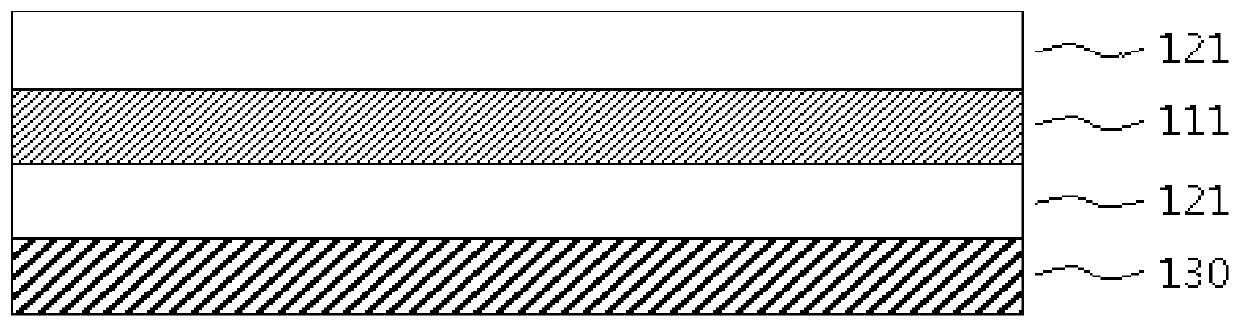

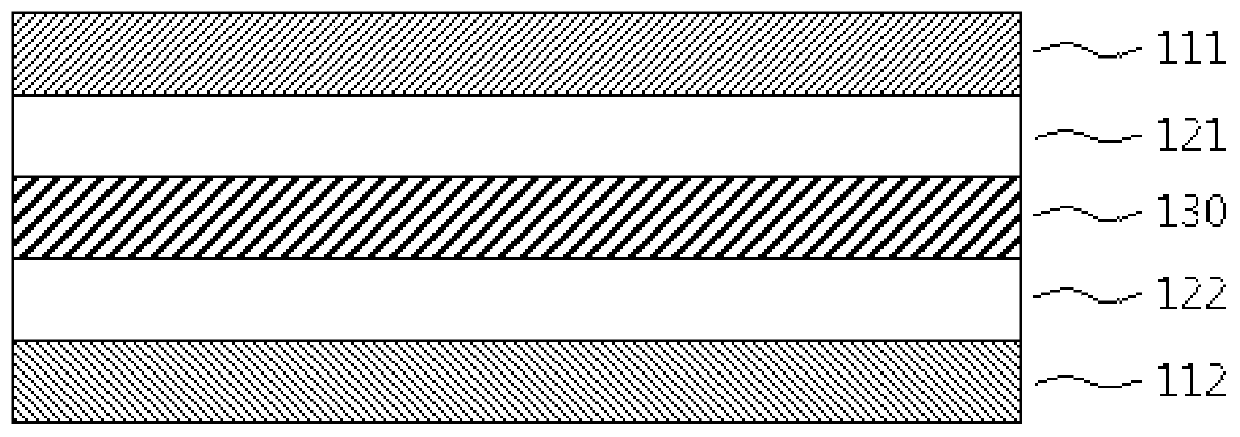

[0067] The preparation method of the hard coating film comprises the following steps: (1) adding polydimethylsiloxane and hydrogen siloxane having vinyl or hexenyl to prepare silicone resin; Coating a composition comprising the silicone resin on the material layer to form a release layer; and (3) coating a hard coating comprising a polymer resin having a glass transition temperature of 30° C. or higher on the release layer layer of resin composition to form a hard coat.

[0068] Each step will be described in detail below.

[0069] The step (1) is a step of preparing a silicone resin by adding polydimethylsiloxane having vinyl or hexenyl groups to hydrogen siloxane.

[0070] The specific types, structures, and reaction amounts of the polydimethylsiloxane and hydrogen siloxane are as exemplified above.

[0071]Specifically, as shown in the chemical formula 1, the polydimethylsiloxane may have a vinyl group or a hexenyl group, whereby the vinyl group or hexenyl group may be co...

Embodiment 1-1

[0089] 10 parts by weight of polydimethylsiloxane (manufactured by Dow Corning, LTC750A), 0.2 parts by weight of hydrosiloxane (manufactured by Dow Corning, 7048), 0.002 parts by weight of platinum catalyst and the remaining amount of solvent (toluene / methyl ethyl ketone mixed solvent) were mixed and stirred to prepare a total of 100 parts by weight of the release layer resin composition. The release layer resin composition was coated on a polyethylene terephthalate film (PET film) with a thickness of 50 μm by a conventional coating method, and then heated and dried at 150° C. for 30 seconds. As a result, a release film in which a release layer with a thickness of 0.5 μm was formed on a PET film was obtained.

Embodiment 1-2

[0091] The same procedure as in Example 1 above was carried out, except that the coating amount of the release layer resin composition was adjusted to prepare a release film in which a release layer with a thickness of 0.05 μm was formed on a PET film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com