Temperature-sensitive CTP type imaging coating

A coating and imaging technology, applied in the field of thermal CTP plate imaging coating, can solve the problems of low printing durability, poor solvent resistance, poor abrasion resistance, etc., to increase mechanical strength, increase solubility, and increase resolution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

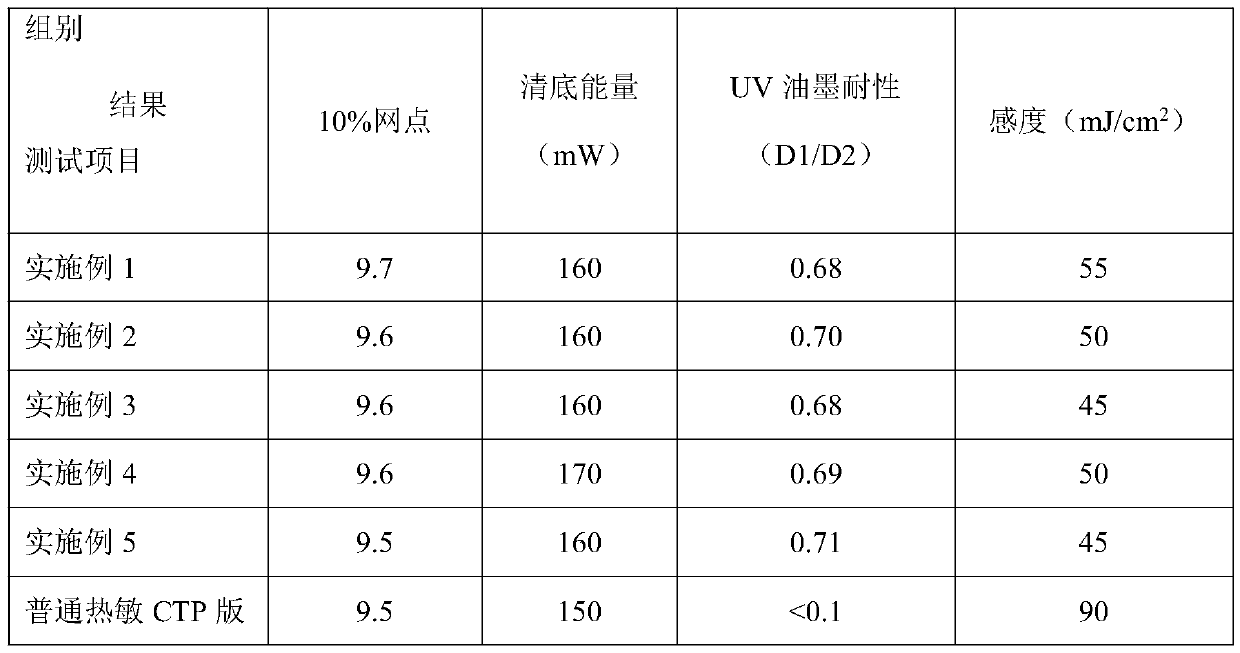

Examples

Embodiment 1

[0033] A heat-sensitive CTP plate imaging coating, which is a single-layer heat-sensitive CTP plate imaging coating, consists of the following components by weight: solvent-resistant resin: 30 parts; alkali-soluble resin: 8 parts; film-forming resin: 20 parts; solubilizer: 5 parts; added resin: 10 parts; solvent-inhibiting and solubilizing resin: 1 part; infrared absorbing dye: 5 parts; dye: 1 part.

[0034] Among them, the solvent-resistant resin is acrylamide-acrylate polymer; the film-forming resin is o- or p-toluenesulfonamide formaldehyde resin as the solubilizer; the solubilizer is sulfonate; the added resin is polyurethane polymer with a molecular weight of 2000- 10000; the infrared absorbing dye is a cyanine dye; the dye is ethyl violet.

Embodiment 2

[0036] A heat-sensitive CTP plate imaging coating, which is a single-layer heat-sensitive CTP plate imaging coating, differs from Example 1 in that it consists of the following components by weight: solvent-resistant resin: 35 parts; alkali-soluble Resin: 8 parts; Film-forming resin: 25 parts; Solubilizer: 6 parts;

Embodiment 3

[0038] A heat-sensitive CTP plate imaging coating, which is a single-layer heat-sensitive CTP plate imaging coating, differs from Example 1 in that it consists of the following components by weight: solvent-resistant resin: 35 parts; alkali-soluble Resin: 8 parts; film-forming resin: 30 parts; solubilizer: 5 parts; additive resin: 12 parts; solvent-inhibiting and solubilizing resin: 1 part;

[0039] Wherein, the solvent-resistant resin is polyacrylamide-tert-butylphenyl acrylate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com