Ferrite core surface epoxy powder coating application process

A ferrite core, epoxy powder technology, applied in powder coatings, epoxy coatings, devices for coating liquid on surfaces, etc., can solve the problem of poor thermal conductivity, low coating adhesion, electrical breakdown, etc. problem, to achieve the effect of improving adhesion, increasing roughness, and improving removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

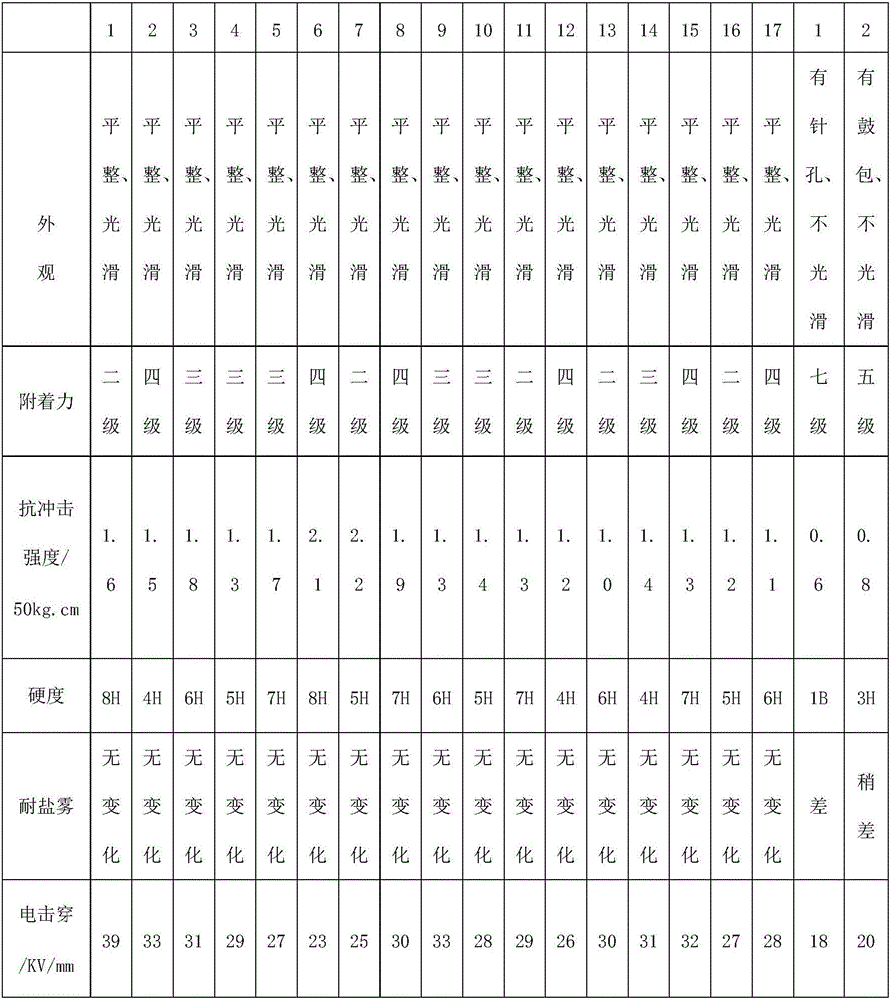

Embodiment 1

[0018] A ferrite magnetic core surface epoxy powder coating process, its preparation method comprises the following steps:

[0019] (1) Weigh 5 parts of sodium chloride, 23 parts of sodium bicarbonate, and 93 parts of water into the reactor, and finally add 38 parts of ethanol, with a stirring speed of 170r / min, and maintain the system temperature at 43°C for 0.8h , to obtain a surface treatment agent;

[0020] (2), Weigh 100 parts of epoxy glossy powder coatings and add them to the ball mill, then weigh 1.8 parts of α-cyanoacrylate, 3 parts of nano-aluminum powder, 3.3 parts of polymethylacrylate, 1.6 parts of melamine resin in 5 parts Add it to the ball mill one by one, react for 2 hours at a temperature of 35°C and a cylinder speed of 49r / min, and screen uniform particles with a particle size of 0.05-0.1mm through a 200-mesh screen to obtain a modified epoxy powder coating;

[0021] (3) Put the ferrite core in 5L of surface treatment agent, clean it for 0.3h at an ultrason...

Embodiment 2

[0025] A ferrite magnetic core surface epoxy powder coating process, its preparation method comprises the following steps:

[0026] (1) Weigh 5 parts of sodium chloride, 17 parts of sodium bicarbonate, and 90 parts of water into the reactor, and finally add 30 parts of ethanol, stir at 150 r / min, and keep the system temperature at 30°C for 0.3 hours. , to obtain a surface treatment agent;

[0027] (2), Weigh 100 parts of epoxy semi-gloss powder coating and add it to the ball mill, then weigh 0.5 parts of sulfated castor oil, 1 part of nano-copper powder, 1 part of polybutylacrylate, and 1 part of melamine resin in 5 times one by one Add it to a ball mill, react for 1 hour at a temperature of 25°C, and a cylinder rotating speed of 35 r / min, and screen uniform particles with a particle size of 0.05 to 0.1 mm through a 200-mesh screen to obtain a modified epoxy powder coating;

[0028] (3) Put the ferrite core in 5L of surface treatment agent, clean it for 0.2h at an ultrasonic ...

Embodiment 3

[0031] A ferrite magnetic core surface epoxy powder coating process, its preparation method comprises the following steps:

[0032] (1) Weigh 5 parts of sodium chloride, 30 parts of sodium bicarbonate, and 100 parts of water into the reactor, and finally add 45 parts of ethanol, with a stirring speed of 200 r / min, and maintain the system temperature at 50°C for 2 hours. get surface treatment agent;

[0033] (2) Weigh 100 parts of epoxy glossy powder coating and add it to the ball mill, then weigh 3 parts of α-cyanoacrylate, 5 parts of nano-silver powder, 4 parts of polymethyl acrylate, and 3 parts of melamine resin for 5 times Add them into the ball mill one by one, react for 3 hours at a temperature of 50°C, and a cylinder rotating speed of 65r / min, and screen uniform particles with a particle size of 0.05-0.1mm through a 200-mesh screen to obtain a modified epoxy powder coating;

[0034] (3) Put the ferrite core in 5L of surface treatment agent, clean it for 0.5h at an ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com