Silver paste suitable for spraying of ceramic filter, and preparation and spraying film forming methods of silver paste

A technology of ceramic filter and silver paste, which is applied in the manufacture of conductive/semiconductive layer equipment, conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, etc., can solve the problem of printing silver paste and dipping Silver paste can not meet the metallization process, screen printing process can not achieve metallization, unfavorable mass production of ceramic filters, etc., to achieve the effect of enhancing storage stability, improving storage stability, and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

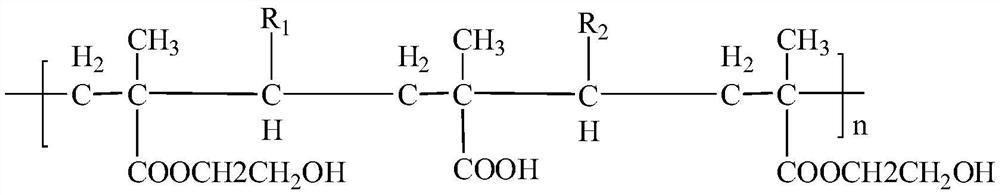

[0022] A silver paste suitable for ceramic filter spraying, comprising the following components in terms of mass percentage: 78% silver powder, the silver powder includes spherical silver powder and flake silver powder, the particle size D50 of the spherical silver powder is 0.5-2.5um, flake silver powder The particle size D50 of spherical silver powder is 2-5um, the weight ratio of spherical silver powder and flake silver powder in silver powder is 10:1, glass powder 2%, 0.8% Bi 2 o 3 , hydroxy acrylic resin 10%, propylene glycol methyl ether acetate 8%, 0.4% leveling agent EFKA3777, 0.4% polyether modified siloxane, 0.3% sodium dodecyl sulfonate, 0.1% pine tar, The chemical structural formula of described hydroxyl acrylic resin is:

[0023]

[0024] In the formula, n is 3, R 1For polyoxyethylene or polyoxypropylene, R 2 is an alkyl group, the molecular weight of the hydroxy acrylic resin is 1200-1400, and the viscosity is 1100-1300mPa.S.

[0025] The glass powder is o...

Embodiment 2

[0029] The difference between embodiment 2 and embodiment 1 is that a silver paste suitable for ceramic filter spraying includes the following components in terms of mass percentage: 80% silver powder, and the silver powder includes spherical silver powder and flake silver powder, spherical silver powder The particle size D50 of silver powder is 0.5-2.5um, the particle size D50 of flake silver powder is 2-5um, the weight ratio of spherical silver powder and flake silver powder in silver powder is 4:1, glass powder 1%, 0.5% CuO, hydroxyl acrylic acid 9.5% resin, 7% terpineol, 0.4% leveling agent EFKA3777, 0.4% polyether modified siloxane, 0.2% sodium dodecyl sulfonate, 0.2% pine tar.

Embodiment 3

[0031] The difference between embodiment 3 and embodiment 1 is that a silver paste suitable for ceramic filter spraying includes the following components in terms of mass percentage: silver powder 75%, and the silver powder includes spherical silver powder and flake silver powder, spherical silver powder The particle size D50 of silver powder is 0.5-2.5um, the particle size D50 of flake silver powder is 2-5um, the weight ratio of spherical silver powder and flake silver powder in silver powder is 5:1, glass powder 1.5%, 0.5% Bi 2 o 3 , 12% hydroxyl acrylic resin, 10% alcohol ester twelve, 0.4% leveling agent EFKA3777, 0.4% polyether modified siloxane, 0.2% 2-ethyl-4-methylimidazole.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com