Nano dye ink for ink jet printing and preparation method thereof

An inkjet printing and nano-pigment technology, applied in the field of color inkjet printing and computer inkjet printing, to achieve the effect of controlling line width, improving printing quality and reducing feathering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation of embodiment 1 red ink

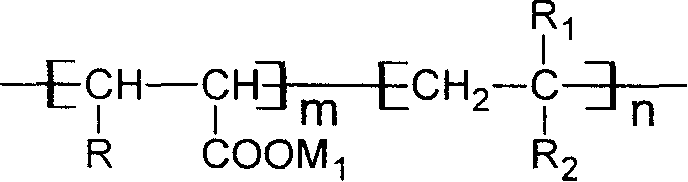

[0024] Get 2g maleic anhydride-methyl methacrylate copolymer ( M n ‾ = 8000 ± 150 , Molar ratio maleic anhydride: methyl methacrylate = 1: 1), add 0.25g sodium hydroxide, 56g deionized water, heat to dissolve the copolymer completely, then add 5g of C.I. Pigment Red 122, 2g of OP- 10 emulsifiers, 15g of diethylene glycol, 10g of ethylene glycol, and 10g of glycerin were stirred with a mixer at 600 rpm for 20 minutes, emulsifier at 10,000 rpm for 40 minutes at a high speed, and pulverized by a sand mill After 90 minutes, adjust the pH value to 9 with sodium hydroxide, and filter with a 0.5-1 μm microporous membrane to obtain a water-based pigment magenta ink. The physical properties of this ink at 20°C are as follows: surface tension σ=30.5mN / m, viscosity η=3.45cP, particle Z average particle size d=105nm,...

Embodiment 2

[0025] The preparation of embodiment 2 yellow ink

[0026] Get 3g styrene-maleic anhydride copolymer, ( M n ‾ = 10000 ± 150 , Molar ratio styrene: maleic anhydride = 1.5: 1), add 0.3g potassium hydroxide, 49g deionized water, heat to dissolve the copolymer completely, then add 7g of C.I. Pigment Yellow 48, 1g Tween 80, 5g N-methyl-2-pyrrolidone, 5g of 1,3-propylene glycol, 20g of polyethylene glycol 200, and 10g of isopropanol were stirred with a mixer at 600 rpm for 50 minutes, and the emulsifier was stirred at a high speed of 10,000 rpm 60 minutes, pulverized by a sand mill for 120 minutes, finally adjusted the pH value to 8, and filtered through a 0.5-1 μm microporous membrane to obtain a water-based pigment yellow ink. The physical properties of this ink at 20°C are as follows: surface tension σ=29.3mN / m, viscosity η=6.5cP, particle Z average partic...

Embodiment 3

[0027] The preparation of embodiment 3 blue ink

[0028] Get 1g of acrylic acid-butyl acrylate copolymer ( M n ‾ = 15000 ± 200 , Molar ratio of acrylic acid: butyl acrylate=1:1.2), add 4g of 20% ammonia water, 57g of deionized water, heat to dissolve the copolymer completely, then add 4g of C.I. Pigment Blue 15:3, 2g of Pingpingjia A-20, 6g of isopropanol, 20g of diethylene glycol, and 10g of pyrrolidone were stirred with a mixer at 500 rpm for 30 minutes, emulsifier at a high speed of 20,000 rpm for 30 minutes, and a sand mill for 80 minutes, and finally adjusted When the pH value reaches 9, filter with a microporous membrane of 0.5-1 μm to obtain the water-based pigment blue ink. The physical properties of this ink at 20°C are as follows: surface tension σ=27.5mN / m, viscosity η=4.35cP, particle Z average particle size d=98nm, Zeta potential ξ=-29.6mV....

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com