Water-rich fault fracture zone collapsed roadway repairing method based on angle-variable umbrella-shaped advancing grouting

A technology of advanced grouting and broken zone, which is applied in the direction of tunnel, earthwork drilling, tunnel lining, etc., can solve the problems of enlarging the broken area of surrounding rock, difficult roadway maintenance, and difficulty in controlling surrounding rock, so as to ensure long-term stability, The effect of reducing blindness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the drawings and embodiments.

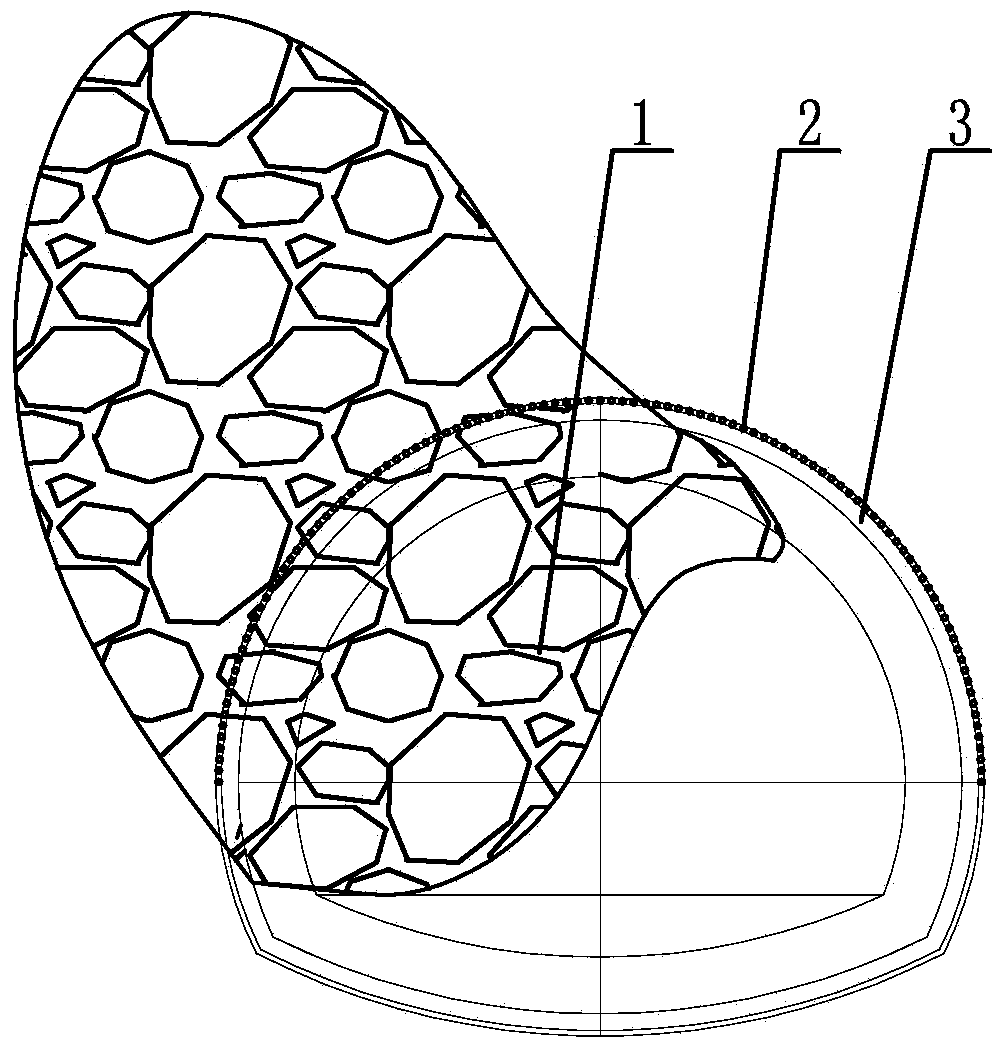

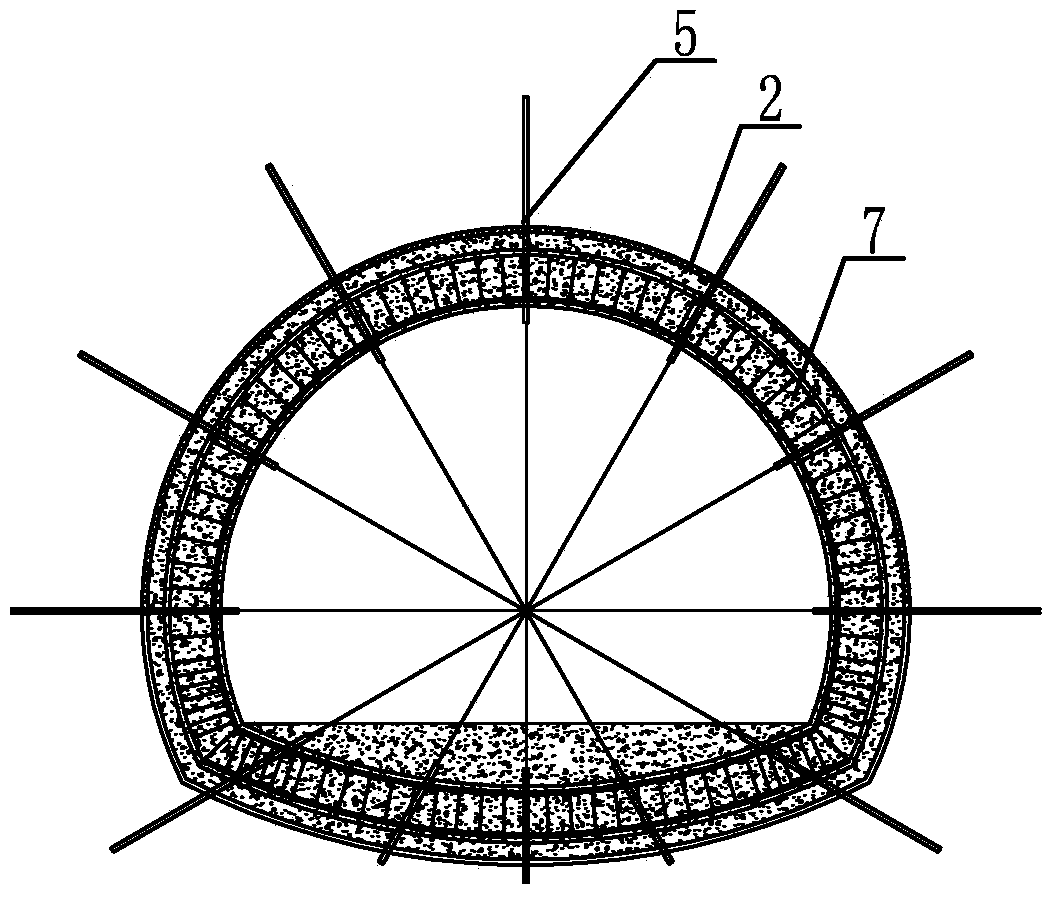

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the present invention includes the following steps:

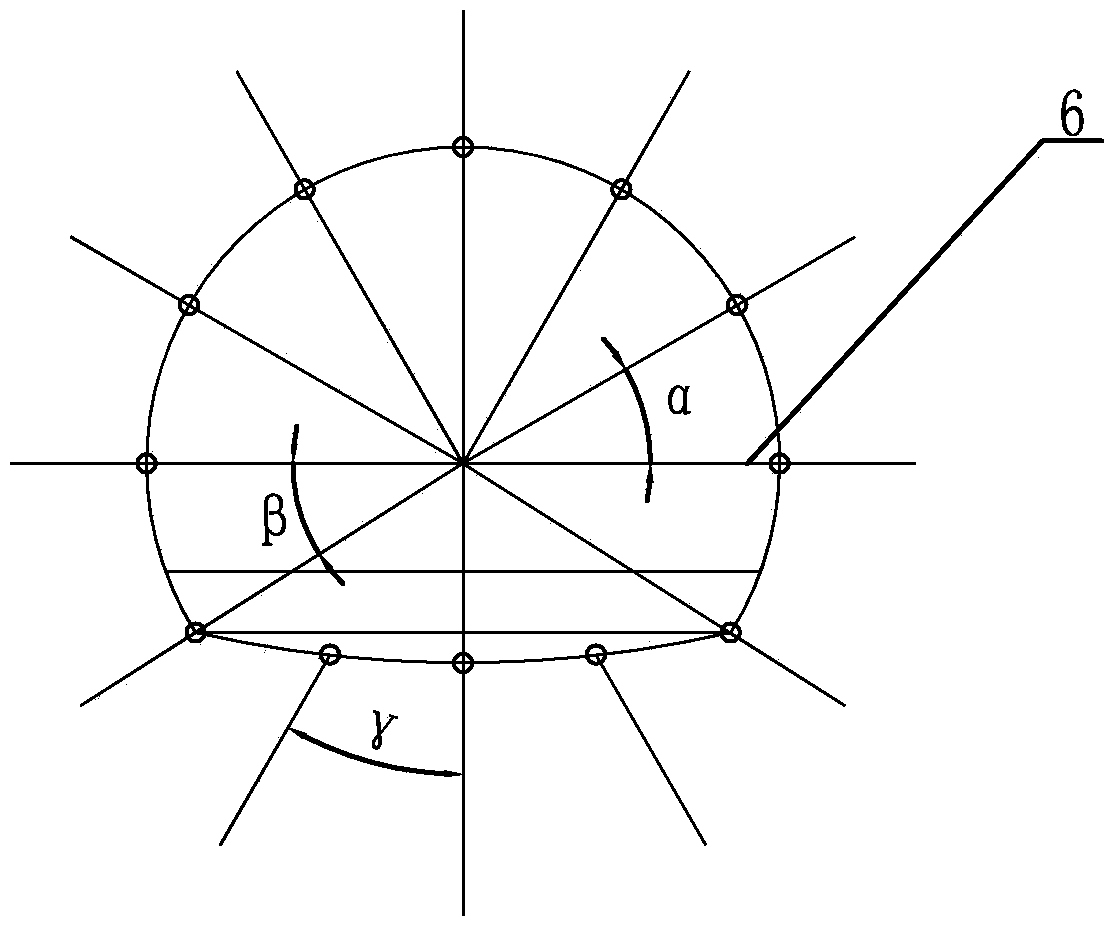

[0032] 1) Water exploration and water diversion are carried out in the inclined well 8-10m behind the roadway deformation zone 1. When drilling, the positions of the hanging holes between the rows are arranged in a plum blossom pattern, and the adjacent drilling rows are arranged in different ways. The grouting range between rows is complementary. All odd-numbered rows are drilled in one-ring hole mode, and all even-numbered rows are drilled in two-ring hole mode. The one-ring hole pattern is to arrange holes at intervals of the arch base line 6 and above at an angle α of 30°, the bottom angle is to arrange the holes along the arch base line 6 below the angle β of 32°, and the bottom plate is below the unilateral center line Holes are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com