Addition-type silicon rubber primer and preparation method thereof

A technology of primer and silicone rubber, applied in the direction of coating, etc., can solve the problems of poor bonding effect and achieve good bonding effect and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

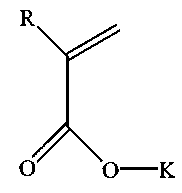

Method used

Image

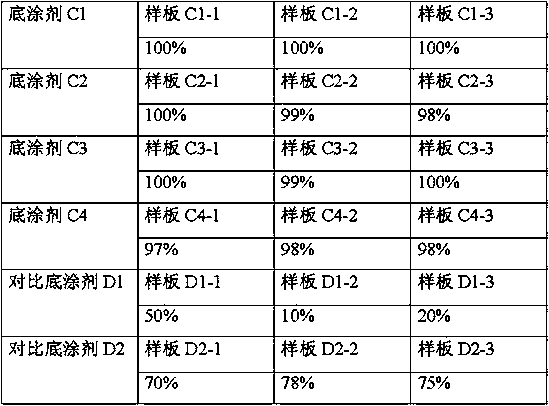

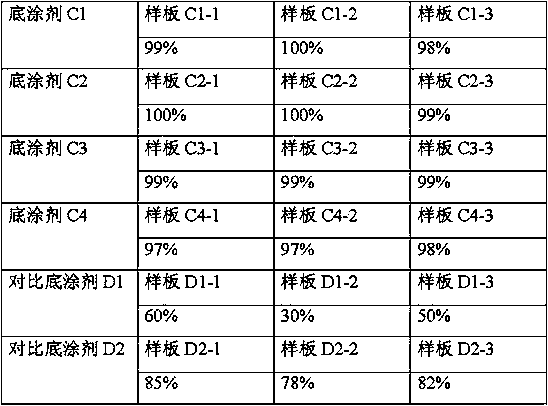

Examples

Embodiment 1

[0049] In a 150mL three-necked flask equipped with a reflux condenser, a stirrer and a thermometer, under N 2 Under protection, add 63.5g butyl acetate solvent, 6gKH-570 silane coupling agent, 30g methyl methacrylate (that is, the molar ratio of acrylic acid monomer to silane coupling agent containing C=C group is 9.4:1 ), 0.7g initiator Luperox270, started to stir slowly for 10min, and slowly raised the temperature to 90°C, and kept the temperature for 2h to obtain the silicone-acrylic acid oligomer A1 of this example.

Embodiment 2

[0051] In a 150mL three-necked flask equipped with a reflux condenser, a stirrer and a thermometer, under N 2 Under protection, add 63g of ethyl acetate solvent, 3g of KH-570 silane coupling agent, 34g of methyl methacrylate (that is, the molar ratio of acrylic acid monomer to silane coupling agent containing C=C group is 15:1) , 0.7g initiator Luperox270, started to stir slowly for 10 minutes, and slowly raised the temperature to 80° C., and kept it warm for 3 hours to obtain the silicone-acrylic acid oligomer A2 of this example.

Embodiment 3

[0053] In a 150mL three-necked flask equipped with a reflux condenser, a stirrer and a thermometer, under N 2 Under protection, add 63g ethyl acetate solvent, 4gA171 silane coupling agent, 38g butyl methacrylate (that is, the molar ratio of acrylic acid monomer to silane coupling agent containing C=C group is 15:1), 0.7 g initiator Luperox270, started to stir slowly for 10 minutes, and slowly raised the temperature to 80° C., and kept the temperature for 2 hours to obtain the silicone-acrylic acid oligomer A3 of this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com