High-flow-state and high-strength non-shrinkage grouting material and preparation method thereof

A non-shrinkage, grouting material technology, applied in the field of construction, can solve the problems of affecting structural safety, poor material homogeneity, and low strength in the later stage, so as to promote continuous hydration, increase water absorption and water retention characteristics, and improve brittleness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation process of the composite anti-segregation agent: pass the sepiolite powder through a 325-mesh sieve, add it into a CaCl salt solution with a mass concentration of 5%, mix and stir, add xanthan gum, and the mass ratio of xanthan gum to sepiolite is 1 :5~1:20, stirring and beating, and heating to 60°C, then adding the initiator (NH 4 ) 2 S 2 o 8 , so that the addition of initiator (NH 4 ) 2 S 2 o 8 The mass ratio of xanthan gum to xanthan gum is 1:100-1:250. After reacting for 2 hours, the product solution is dried in a vacuum drying oven at 60°C and crushed to prepare a composite anti-segregation agent.

[0035] The inorganic modified sepiolite powder is a kind of porous inorganic mineral fiber, the fiber length is mostly 10 μm, the internal micropores are many, the specific surface area is large, and the specific surface area is greater than 4750m 2 .kg -1 .

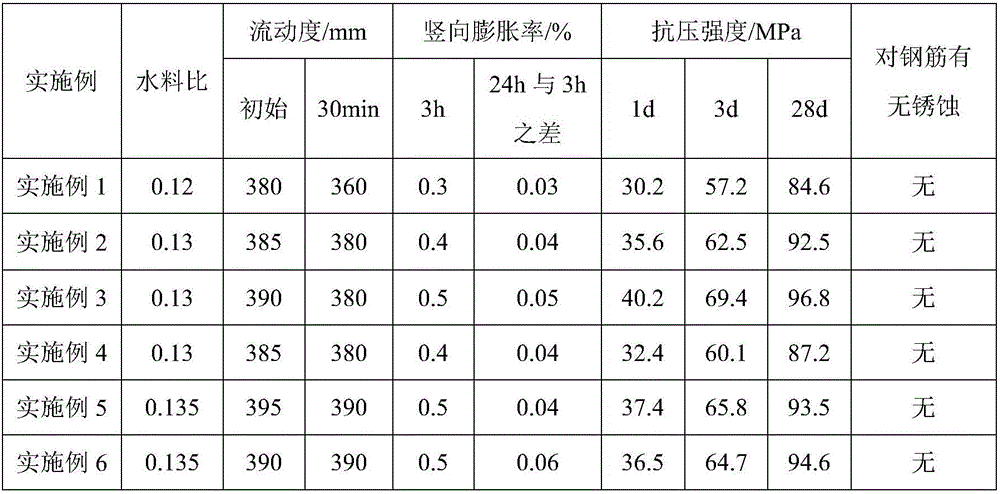

Embodiment 1

[0039] A high-fluidity high-strength non-shrinkage grouting material, the components of which are calculated by mass percentage:

[0040] Ordinary 42.5 grade Portland cement 30%;

[0041] Mineral admixture 14%;

[0042] Dolomite composite powder 3.3%;

[0043] Composite expansion agent 2%;

[0044] Washed sand 50%;

[0045] Polycarboxylate superplasticizer 0.5%;

[0046] Builder 0.2%.

[0047] The preparation method of the large-flow high-strength non-shrinkage grouting material described in this example includes the following steps: weighing the synergist and the polycarboxylate superplasticizer according to the mass ratio, and first using a small dry powder mixer to mix for 3 minutes~ 5min, then weigh the components of the cementitious material and the aggregate according to the mass ratio, and then put them into the mixer and stir for 30min to 50min to make a large fluid, high-strength, non-shrinking dry powder grouting material; when using, add 10wt of the dry powder ...

Embodiment 2

[0049] A high-fluidity high-strength non-shrinkage grouting material, the components of which are calculated by mass percentage:

[0050] Ordinary 42.5 grade Portland cement 40%;

[0051] Mineral admixture 6%;

[0052] Dolomite composite powder 5.9%;

[0053] Composite expansion agent 2%;

[0054] Washed sand 45%;

[0055] Polycarboxylate superplasticizer 0.6%;

[0056] Builder 0.5%.

[0057] The preparation method of the large-flow high-strength non-shrinkage grouting material described in this example includes the following steps: weighing the synergist and the polycarboxylate superplasticizer according to the mass ratio, and first using a small dry powder mixer to mix for 3 minutes~ 5min, then weigh the components of the cementitious material and the aggregate according to the mass ratio, and then put them into the mixer and stir for 30min to 50min to make a large fluid, high-strength, non-shrinking dry powder grouting material; when using, add 10wt of the dry powder g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com