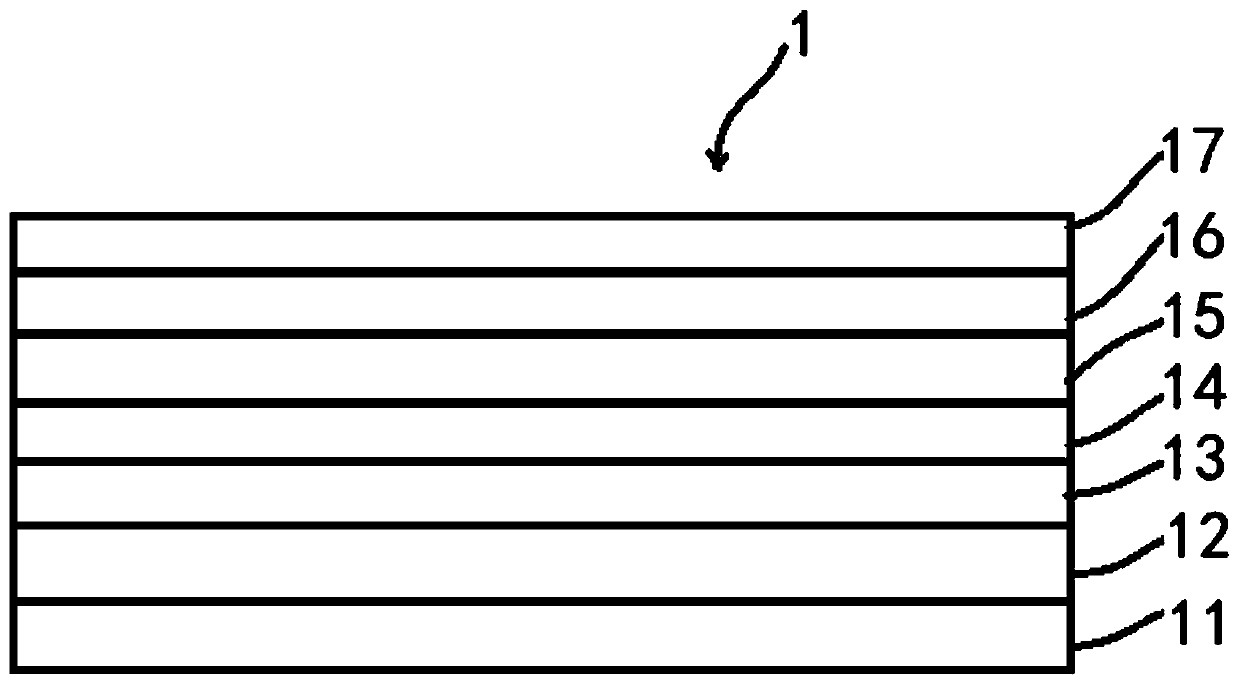

Electron transport layer ink, preparation method thereof and electroluminescence device

An electron transport layer and ink technology, which is applied to electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of device preparation difficulties, and achieve the effects of simple preparation method, suppression of damage, and enhancement of electron injection and transmission capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

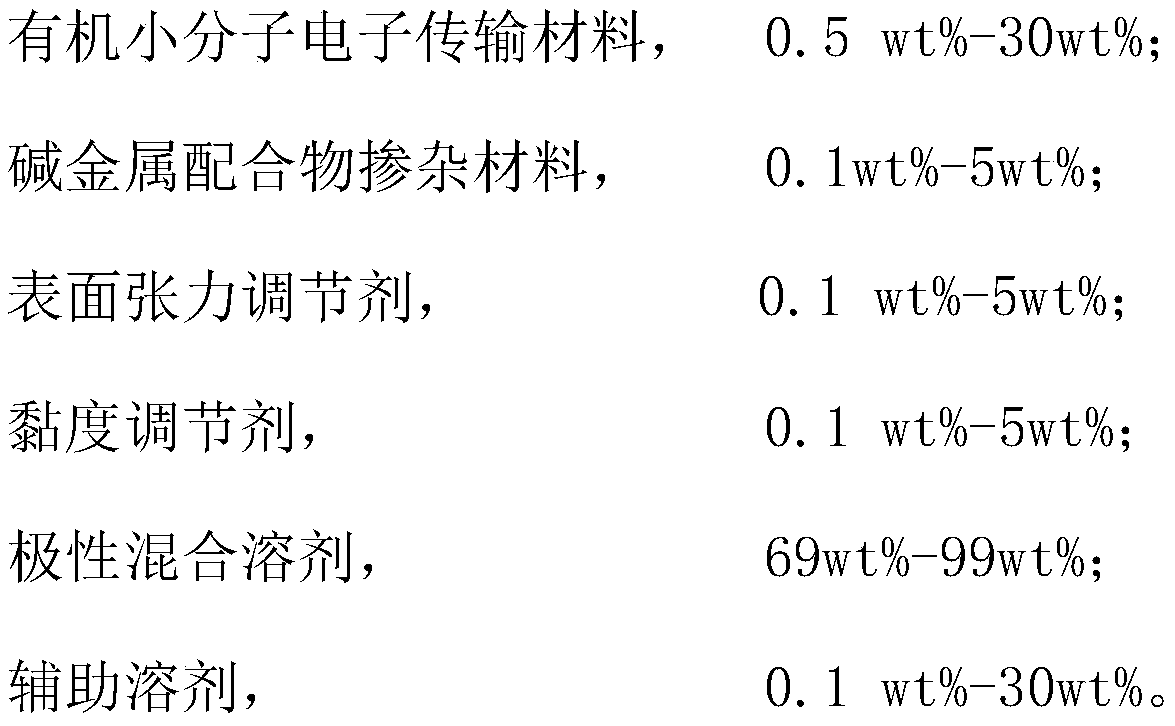

[0032] The electronic transport layer ink of the present invention, its components include organic small molecule electron transport material, 30wt%; alkali metal complex doping material, 0.1wt%; surface tension regulator, 0.1wt%; viscosity regulator , 0.1wt%; polar mixed solvent, 69wt%; auxiliary solvent, 0.7wt%.

[0033] 2,2'-(1,3-phenyl)bis[5-(4-tert-butylphenyl)-1,3,4-oxadiazole] is selected as the small organic molecule electron transport material. The alkali metal complex doping material is lithium 8-hydroxyquinolate. In the surface tension modifier, dimethylformamide is selected as a co-solvent, sodium alkylbenzenesulfonate as a surfactant, and hydroquinone as a small molecule compound for regulating surface tension;

[0034] The viscosity regulator is selected from amine compounds. The polar mixed solvent is a polyalcohol compound, and ethylene glycol is selected in this embodiment. The auxiliary solvent is selected from amide compounds.

[0035] This embodiment al...

Embodiment 2

[0037]The electronic transport layer ink of the present invention, its components include organic small molecule electron transport material, 10wt%; alkali metal complex doping material, 2wt%; surface tension regulator, 2wt%; viscosity regulator, 2wt% by weight percentage. %; polar mixed solvent, 80wt%; auxiliary solvent, 4wt%.

[0038] 1,3,5-tris(1-phenyl-benzo[D]pyrazol-2-yl)benzene is selected as the small organic molecule electron transport material. The alkali metal complex doping material is lithium 8-hydroxyquinolate.

[0039] In the surface tension regulator, cyclohexane is used as a co-solvent, sodium alkylbenzenetripolyethylene sulfonate is used as a surfactant, and imidazole and its derivatives are small molecular compounds for regulating surface tension.

[0040] The viscosity regulator is selected from ether compounds. The polar mixed solvent is a polyalcohol compound, and ethylene glycol is selected in this embodiment. The auxiliary solvent is selected from et...

Embodiment 3

[0043] The electron transport layer ink of the present invention, its component comprises organic small molecule electron transport material, 5wt% by weight percentage; Alkali metal complex doping material, 5wt%; Surface tension regulator, 5wt%; Viscosity regulator, 5wt% %; polar mixed solvent, 69wt%; auxiliary solvent, 11wt%.

[0044] 2,2'-(1,3-phenyl)bis[5-(4-tert-butylphenyl)-1,3,4-oxadiazole] is selected as the small organic molecule electron transport material. The alkali metal complex doping material is lithium 8-hydroxyquinolate. In the surface tension modifier, dimethylformamide is selected as a co-solvent, sodium alkylbenzenesulfonate as a surfactant, and hydroquinone as a small molecule compound for regulating surface tension;

[0045] The viscosity regulator is selected from amine compounds. The polar mixed solvent is a polyalcohol compound, and ethylene glycol is selected in this embodiment. The auxiliary solvent is selected from amide compounds.

[0046] Tests...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com