Nano dye ink for ink jet printing and preparation method thereof

A technology of inkjet printing and nano pigments, which is applied in the fields of computer inkjet printing and color inkjet printing, to achieve the effects of controlling line width, reducing feathering, and good printability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation of embodiment 1 red ink

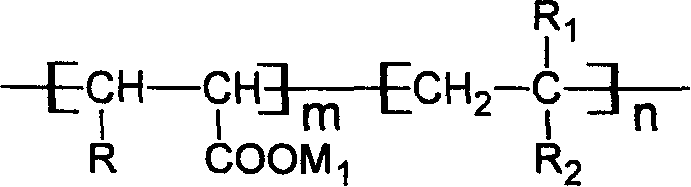

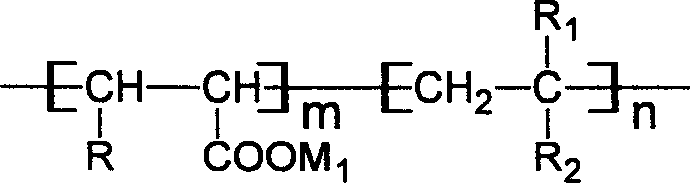

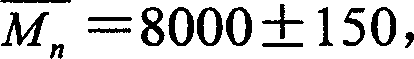

[0024] Get 2g maleic anhydride-methyl methacrylate copolymer ( M n ‾ = 8000 ± 150 , Molar ratio maleic anhydride: methyl methacrylate = 1: 1), add 0.25g sodium hydroxide, 56g deionized water, heat to dissolve the copolymer completely, then add 5g of C.I. Pigment Red 122, 2g of OP- 10 emulsifiers, 15g of diethylene glycol, ethylene glycol of 10g, 10g of glycerin, stir respectively with mixer 600 rev / min for 20 minutes, emulsifier 10000 rev / min for 40 minutes at high speed, sand mill pulverize After 90 minutes, adjust the pH value to 9 with sodium hydroxide, and filter with a 0.5-1 μm microporous membrane to obtain a water-based pigment magenta ink. The physical properties of this ink at 20°C are as follows: surface tension σ=30.5mN / m, viscosity η=3.45cP, particle Z average particle size d=105nm, Zeta poten...

Embodiment 2

[0025] The preparation of embodiment 2 yellow ink

[0026] Get 3g styrene-maleic anhydride copolymer, ( M n ‾ = 10000 ± 150 , Molar ratio styrene: maleic anhydride = 1.5: 1), add 0.3g potassium hydroxide, 49g deionized water, heat to dissolve the copolymer completely, then add 7g of C.I. Pigment Yellow 48, 1g Tween 80, 5g N-methyl-2-pyrrolidone, 5g of 1,3-propylene glycol, 20g of polyethylene glycol 200, and 10g of isopropanol were stirred with a mixer at 600 rpm for 50 minutes, and the emulsifier was stirred at a high speed of 10,000 rpm 60 minutes, pulverized by a sand mill for 120 minutes, finally adjusted the pH value to 8, and filtered through a 0.5-1 μm microporous membrane to obtain a water-based pigment yellow ink. The physical properties of this ink at 20°C are as follows: surface tension σ=29.3mN / m, viscosity η=6.5cP, particle Z average partic...

Embodiment 3

[0027] The preparation of embodiment 3 blue ink

[0028] Get 1g of acrylic acid-butyl acrylate copolymer ( M n ‾ = 15000 ± 200 , Molar ratio of acrylic acid: butyl acrylate=1:1.2), add 4g of 20% ammonia water, 57g of deionized water, heat to dissolve the copolymer completely, then add 4g of C.I. Pigment Blue 15:3, 2g of Pingpingjia A-20, 6g of isopropanol, 20g of diethylene glycol, and 10g of pyrrolidone were stirred with a mixer at 500 rpm for 30 minutes, emulsifier at a high speed of 20,000 rpm for 30 minutes, and a sand mill for 80 minutes, and finally adjusted When the pH value reaches 9, filter with a microporous membrane of 0.5-1 μm to obtain the water-based pigment blue ink. The physical properties of this ink at 20°C are as follows: surface tension σ=27.5mN / m, viscosity η=4.35cP, particle Z average particle size d=98nm, Zeta potential ξ=-29.6mV....

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com