Dihydric alcohol type active dye ink

A technology of reactive dyes and diols, applied in the field of textile printing, can solve the problems of easy hydrolysis of reactive pigments, poor performance stability, and poor moisture retention, and achieve the effects of improving stability, good moisture retention, and avoiding delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A kind of dibasic alcohol reactive dye ink, comprises the following raw materials measured by mass parts:

[0017]

[0018] Wherein, the buffer is Na 2 HPQ 4 and citric acid; the pH value of the reactive dye ink is adjusted to 6.5-7.3 by the buffering agent. The surfactant is a naphthalenesulfonic acid surfactant.

[0019] The preparation method of the above-mentioned reactive dye ink: take ethylene glycol, 1,3-propanediol, 1,2-hexanediol ethanol and diethylene glycol in proportion and mix evenly, add active pigment, stir well, and then add buffer, surface The active agent and deionized water are fully stirred at 55° C. for 25-30 minutes, mixed evenly, and then filtered through a 600-mesh gauze to obtain a reactive dye ink.

Embodiment 2

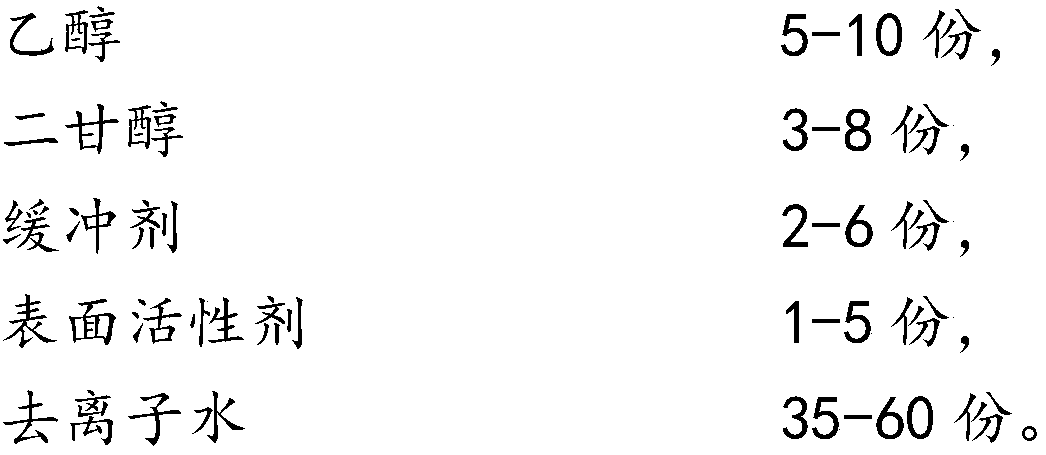

[0021] A kind of dibasic alcohol reactive dye ink, comprises the following raw materials measured by mass parts:

[0022]

[0023]

[0024] Wherein, the buffer is Na 2 HPQ 4 and citric acid; the pH value of the reactive dye ink is adjusted to 6.5-7.3 by the buffering agent. The surfactant is a naphthalenesulfonic acid surfactant.

[0025] The preparation method of the above-mentioned reactive dye ink: take ethylene glycol, 1,3-propanediol, 1,2-hexanediol ethanol and diethylene glycol in proportion and mix evenly, add active pigment, stir well, and then add buffer, surface The active agent and deionized water are fully stirred at 55° C. for 25-30 minutes, mixed evenly, and then filtered through a 600-mesh gauze to obtain a reactive dye ink.

Embodiment 3

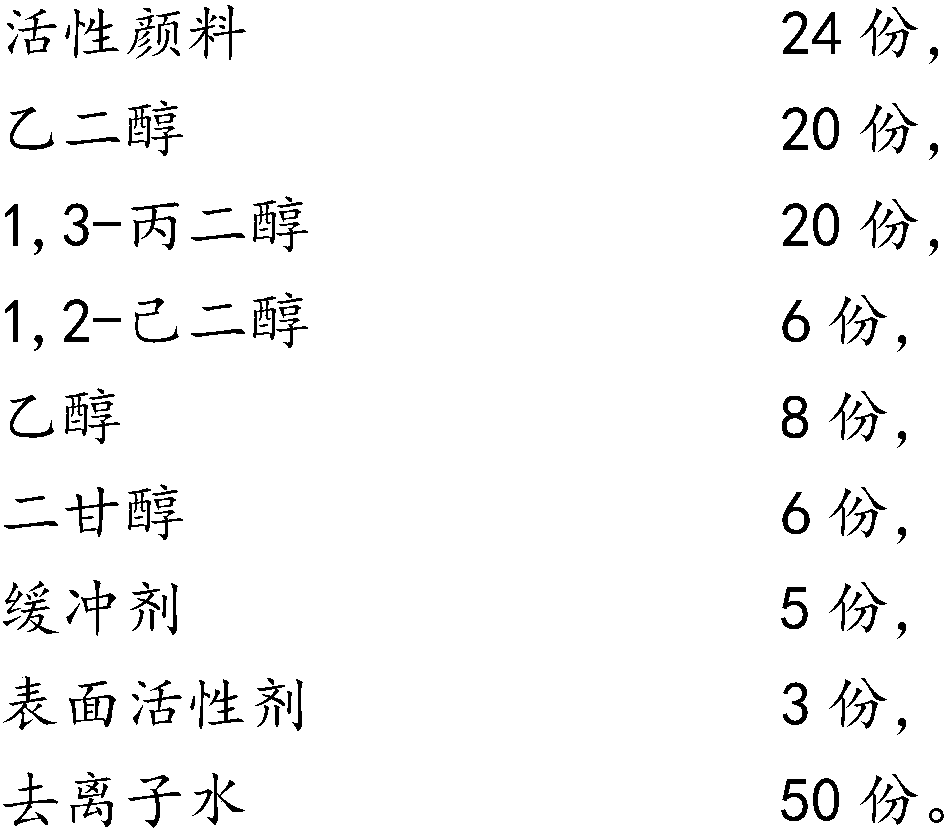

[0027] A kind of dibasic alcohol reactive dye ink, comprises the following raw materials measured by mass parts:

[0028]

[0029] Wherein, the buffer is Na 2 HPQ 4 and citric acid; the pH value of the reactive dye ink is adjusted to 6.5-7.3 by the buffering agent. The concentration of dihydric alcohol in the reactive dye ink is controlled at 2.8-3.3mol / L. The surfactant is a naphthalenesulfonic acid surfactant.

[0030] The preparation method of the above-mentioned reactive dye ink: take ethylene glycol, 1,3-propanediol, 1,2-hexanediol ethanol and diethylene glycol in proportion and mix evenly, add active pigment, stir well, and then add buffer, surface The active agent and deionized water are fully stirred at 55° C. for 25-30 minutes, mixed evenly, and then filtered through a 600-mesh gauze to obtain a reactive dye ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com