Method for preparing egg membrane element by subcritical method

A subcritical and egg-film technology, which is applied in pharmaceutical formulations, toiletry preparations, cosmetic preparations, etc., can solve the problems of microbial contamination, low extraction efficiency, decomposition rate and yield, and achieve the adjustment of oil-water surface tension, Reduce production cost and improve antioxidant activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

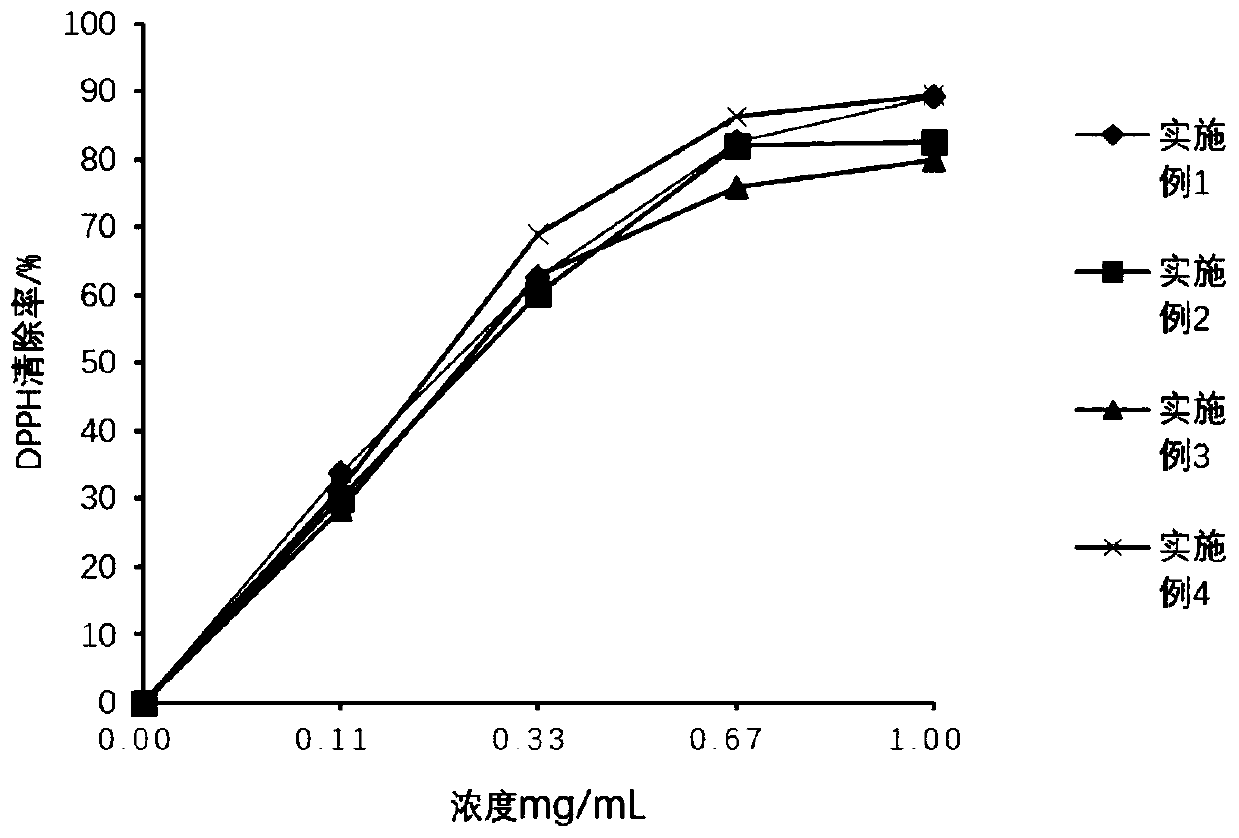

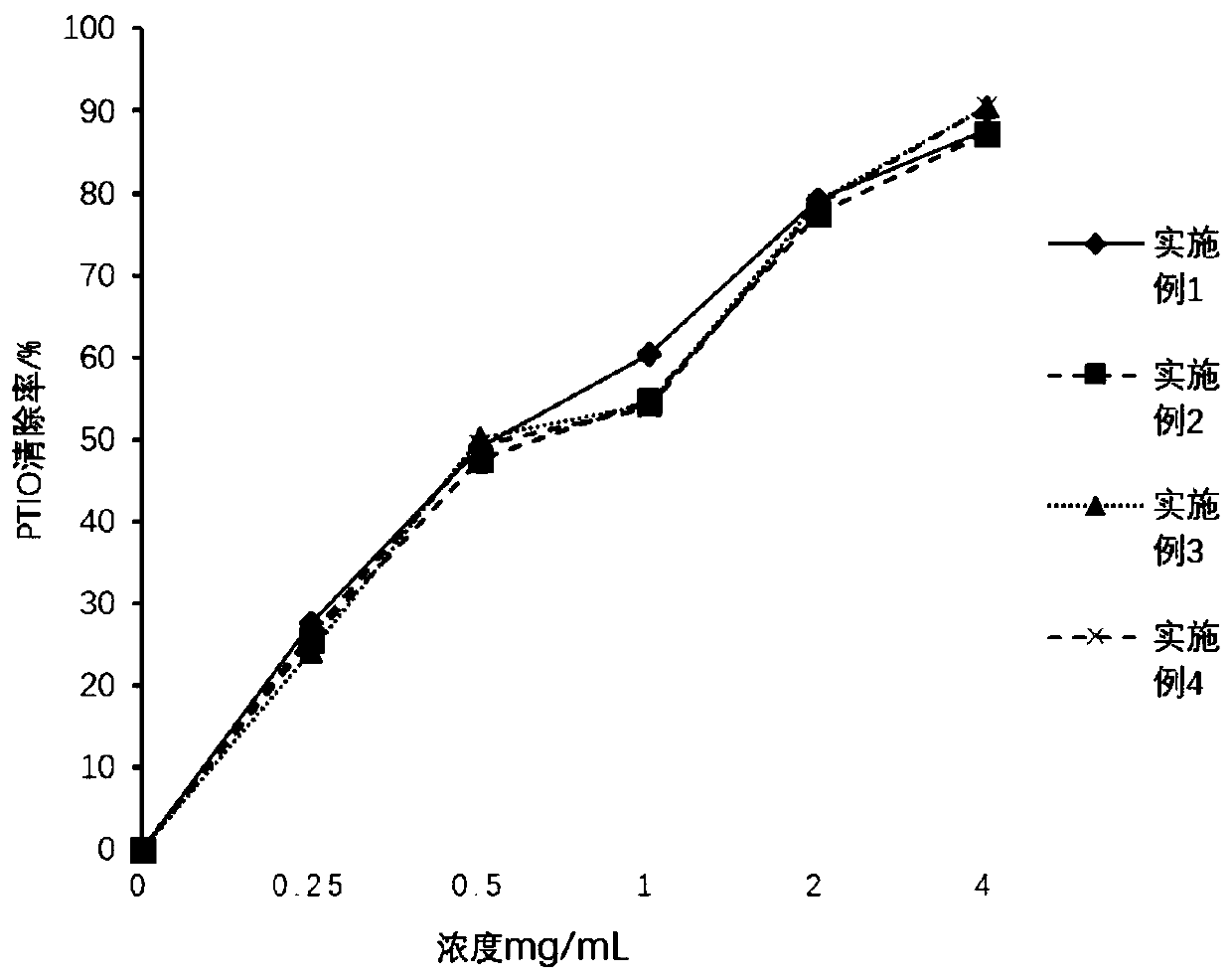

Examples

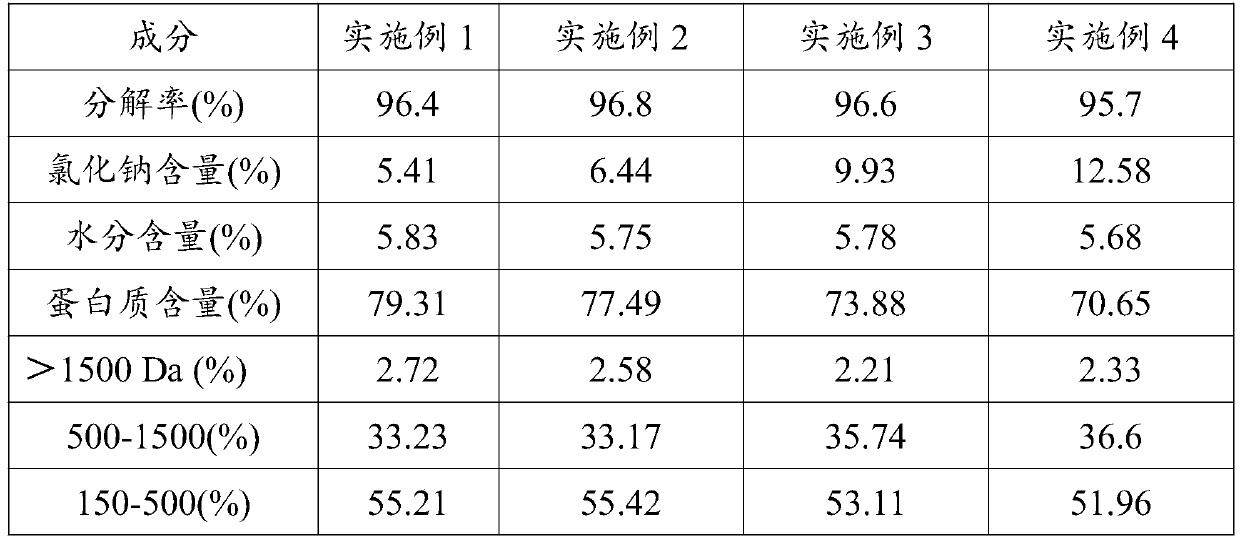

Embodiment 1

[0039] Using the ultrasonic method, the egg shells are cleaned with clear water (the mass ratio of clear water to egg shells is 4:1), the frequency of the ultrasonic wave is 10min / time, until the egg shells are free of egg whites, egg yolks and other foreign matter, and then dried to obtain clean Egg shells; then according to the method disclosed in Chinese patent document CN109276579A, using the clean egg shells to prepare eggshell membranes;

[0040] Take 5g of eggshell membrane and add it to 300mL of aqueous solution containing 0.25g of sodium hydroxide, mix well and then transfer to a subcritical reactor. The time is 1h, subcritical decomposition is carried out; after the decomposition is completed, the pH value of the obtained supernatant is adjusted to 6.8 with 0.5mol / L hydrochloric acid to obtain a decomposition solution; the decomposition solution is centrifuged at 10000r / min for 10min, and the upper The supernatant liquid was spray-dried to obtain ovalvin powder, and ...

Embodiment 2

[0043] Take 5g of eggshell membrane and add it to 300mL of aqueous solution containing 0.34g of sodium hydroxide, mix well and then transfer to a subcritical reactor. The subcritical conditions are: temperature 140°C, pressure 0.5MPa, stirring speed 350r / min , the time is 1h, carry out subcritical decomposition; after the decomposition is completed, the pH value of the supernatant obtained is adjusted to 7.0 with 0.8mol / L hydrochloric acid to obtain a decomposition solution, which is centrifuged at a speed of 10000r / min for 10min, and taken The supernatant was spray-dried to obtain ovalvin powder, and the spray-drying conditions were: outlet temperature 60°C, inlet temperature 190°C.

Embodiment 3

[0045] Take 10g of eggshell membrane and add it to 300mL of aqueous solution containing 0.8g of sodium hydroxide, mix well and then transfer to a subcritical reactor. The subcritical conditions are: temperature 130°C, pressure 2.0MPa, stirring speed 300r / min , the time is 0.5h, carry out subcritical decomposition; after the decomposition is completed, the pH value of the supernatant obtained is adjusted to 7.0 with 1mol / L hydrochloric acid to obtain a decomposition solution, which is centrifuged at 8000r / min for 8min, and taken The supernatant was spray-dried to obtain ovalvin powder, and the spray-drying conditions were: outlet temperature 70°C, inlet temperature 195°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com