Multifunctional inorganic diatom ooze coating and preparation method thereof

A diatom mud coating, multi-functional technology, applied in the direction of alkali metal silicate coatings, antifouling/underwater coatings, coatings, etc. Insufficient force, low water resistance of coatings and other problems, to achieve excellent storage stability, optimize brittleness, and improve bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

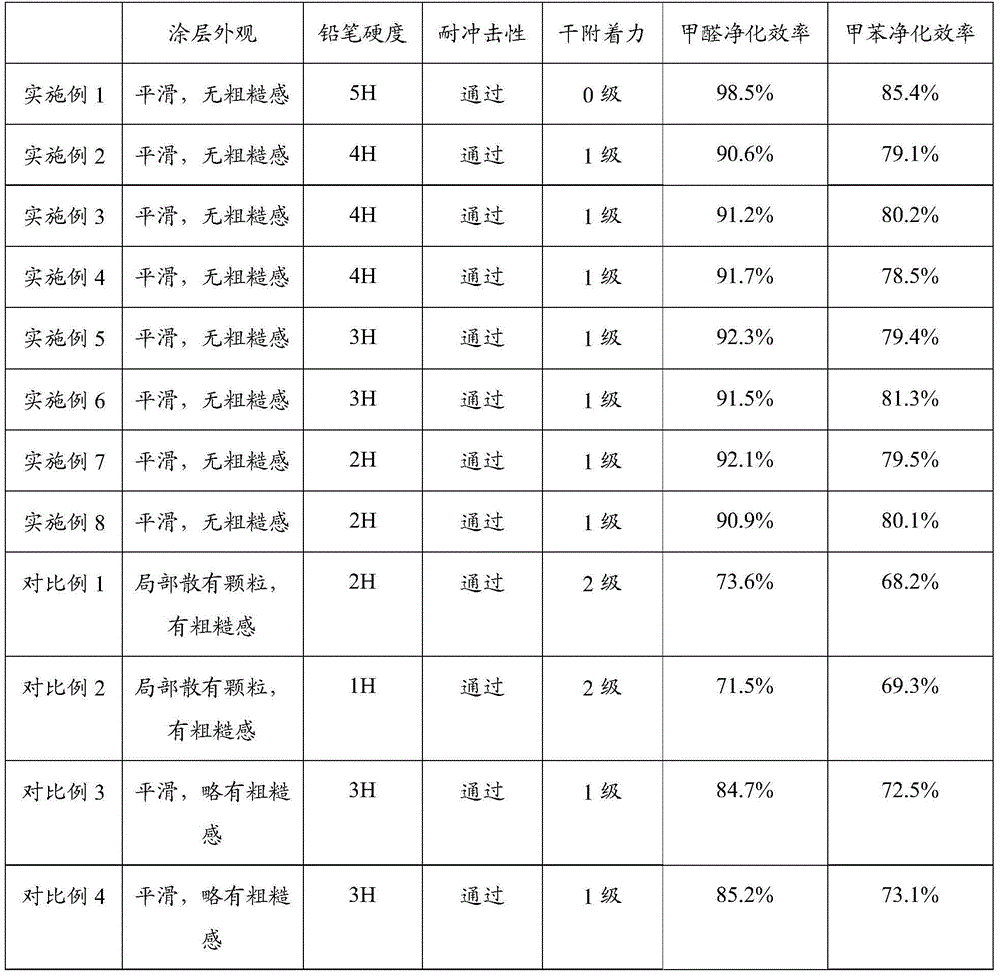

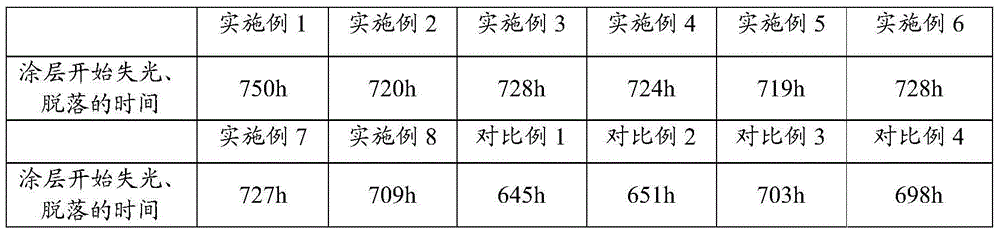

Examples

Embodiment 1

[0041] A kind of multifunctional inorganic diatom mud coating, it is made of the following components by weight percentage:

[0042] Water 21.4%, hydroxypropyl cellulose 0.6%, mixture of potassium silicate and silica sol 20%, calcium stearate 0.3%, methyl amyl alcohol 0.2%, simethicone 0.2%, tributyl phosphate 0.4% , silver oxide 0.2%, titanium dioxide 10%, nano diatomite 13%, heavy calcium 18%, talcum powder 3%, medical stone 2%, nano negative ion powder 1%, nano titanium dioxide 1%, magnesium aluminum silicate 1.7% rubber powder, 6% pure flavor emulsion, 1% pigment; the mass ratio of the mixture of potassium silicate and silica sol to potassium silicate is 10:7, and the negative ion generation amount of the nano negative ion powder is 20000ionsS / CC, the particle size of the heavy calcium is 800 mesh.

[0043] Its preparation method comprises the following steps in turn:

[0044] a. Weigh each component according to the formula, add water and cellulose into the stirring co...

Embodiment 2

[0051] A multifunctional inorganic diatom mud coating, which is made of the following components by weight percentage: 11.3% water, 0.5% hydroxypropyl cellulose, 30% mixture of potassium silicate and silica sol, calcium stearate 0.3%, methyl amyl alcohol 0.2%, simethicone 0.2%, tributyl phosphate 0.3%, silver oxide 0.2%, titanium dioxide 15%, nano diatomite 10%, heavy calcium 22%, talc 4% , medical stone 2%, nano-anion powder 0.5%, nano-titanium dioxide 0.5%, magnesium-aluminum silicate gel powder 2%, net taste emulsion 0%, pigment 1%; the quality of the mixture of potassium silicate and silica sol The mass ratio with potassium silicate is 10:7, the negative ion generating capacity of the nano negative ion powder is 20000 ionS / CC, and the particle diameter of the heavy calcium is 800 mesh. Its preparation method is with embodiment 1.

Embodiment 3

[0053] A multifunctional inorganic diatom mud coating, which is made of the following components by weight percentage: 16% water, 0.6% hydroxypropyl cellulose, 25% mixture of potassium silicate and silica sol, calcium stearate 0.3%, methyl amyl alcohol 0.2%, simethicone 0.2%, tributyl phosphate 0.4%, silver oxide 0.2%, titanium dioxide 5%, nano diatomite 12%, heavy calcium 26%, talc 4% , medical stone 2%, nano-anion powder 1%, nano-titanium dioxide 0.6%, magnesium-aluminum silicate gel powder 1.5%, net taste emulsion 4%, pigment 1%; the quality of the mixture of potassium silicate and silica sol The mass ratio with potassium silicate is 10:7, the negative ion generating capacity of the nano negative ion powder is 20000 ionS / CC, and the particle diameter of the heavy calcium is 800 mesh. Its preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com