Silicon steel water-soluble environment-friendly super thick insulating coating and preparation method thereof

An insulating coating, water-soluble technology, applied in the field of silicon steel water-soluble environmental protection extremely thick insulating coating and its preparation, can solve the problems of not being suitable for large and medium-sized generators, small surface insulation resistance, low thermal compression rate of laminations, etc. , to achieve the effect of good thermal compression resistance, excellent insulation performance and low VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

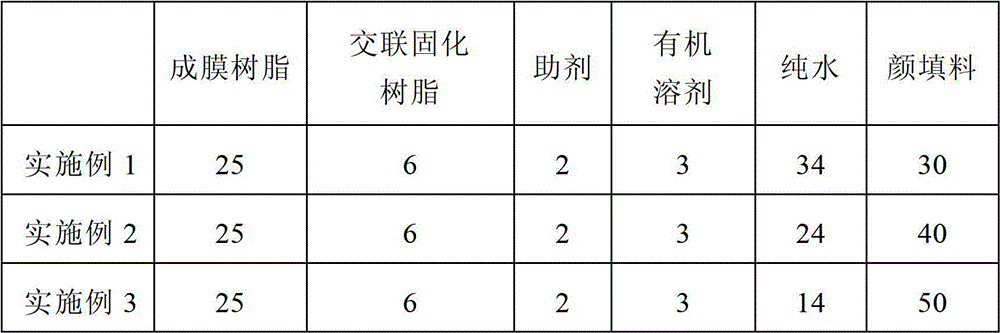

[0055] The effects of different pigment and filler contents on the insulation properties of coatings were compared. Examples of the present invention are shown in Table 1. The formula coating solution is applied on the surface of non-oriented silicon steel plate by a roller coater, and baked to form a film under the conditions of a set temperature of 240°C and a heat preservation of 30 minutes (the plate temperature is 240°C) using a box-type muffle furnace. The dry film thickness of one side of the control coating is 5 μm. The coating performance evaluation results are shown in Table 2.

[0056] (Note 1: Evaluation symbols are ◎best; ⊙excellent; ○better; △average; ×poor)

[0057] (Note 2: All the data in the formula table are parts by mass)

[0058] (Note 3: Comparative Example 1 refers to the coating ratio of Chinese Patent Application No. 200710144412.2; Comparative Example 2 refers to the coating ratio of Example 6 in Chinese Patent Application No. 200810207262.X)

[0...

Embodiment 2

[0065] The effects of different resin contents on the general mechanical properties of coatings were compared. The formulation of silicon steel environmental protection extremely thick insulating coating liquid is shown in Table 3. The formula coating solution is coated on the surface of non-oriented silicon steel plate by roller coater, and baked under the conditions of continuous open flame baking furnace, setting the furnace temperature at 280°C, and heating time for 70 seconds (the plate temperature is 270°C). Bake to form a film, and control the dry film thickness of one side of the coating to 5 μm. The coating performance results are shown in Table 4.

[0066] Table 3 Unit: weight percentage

[0067]

Film-forming resin

Cross-linked curing resin

Auxiliary

Organic solvents

pure water

Pigments

Example 5

20

4.8

2

4

24.2

45

Example 6

25

6

2

4

18

45

Ex...

Embodiment 3

[0071] The coating results of Example 1 and Example 2 were formulated to be optimized, and a series of formulations with better comprehensive properties were obtained (Table 5). The properties of insulating coatings obtained from each formulation are shown in Table 6. Apply the coating solution of each formula on the surface of the non-oriented silicon steel plate, and bake it in a continuous open flame baking furnace with the furnace temperature set at 320°C and the heating time at 30 seconds (the plate temperature is 260°C). Film, control the dry film thickness of one side of the coating to 4~6μm. The coating performance results are shown in Table 7. The cured coating is dense and tough, and the SEM photos of its surface are as follows: figure 1 As shown, the surface is smooth, dense, uniform and flat; the cross-sectional SEM photo is shown in figure 2 As shown, the cross-section is dense and the particle size of the inorganic filler is small.

[0072] table 5

[0073] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com