Preparation method of aluminum sludge ceramsite

A technology of aluminum sludge and ceramsite, which is applied in the production of ceramic products, clay products, ceramic materials, etc., can solve the problems of clay application limitations, achieve the effects of resource utilization of waste, saving disposal costs, and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

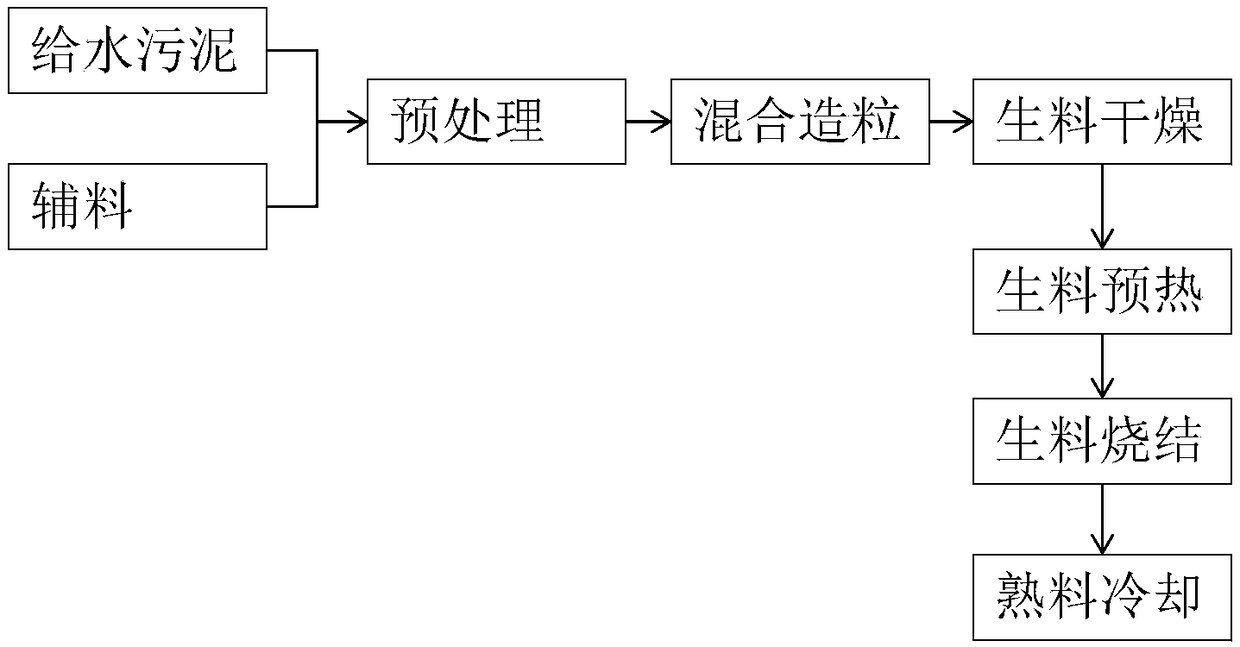

[0037] Such as figure 1 Shown, a kind of aluminum sludge ceramsite preparation method of the present invention comprises the steps:

[0038] The sludge from the water supply plant is used as the main material, pretreated first, and then ground into 80-mesh sieves with auxiliary materials such as fly ash, clay and glass powder for use; then mixed with water and stirred evenly, mixed and granulated to prepare raw ceramsite. After drying, preheating, firing and cooling, the preparation process is completed.

[0039] The material selection of the main material and the auxiliary material of the present invention mainly considers factors such as waste utilization, material cost saving, transportation cost and the like. The pretreatment of raw materials in the present invention mainly considers that the shape, size and moisture content of the raw mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com