Gradient single-crystal positive electrode material, preparation method and application

A positive electrode material and single crystal technology, applied in the field of gradient single crystal positive electrode materials, can solve the problems of battery life attenuation, particle breakage, poor rate performance, etc., to improve high voltage performance, prevent structural stability, and excellent rate performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

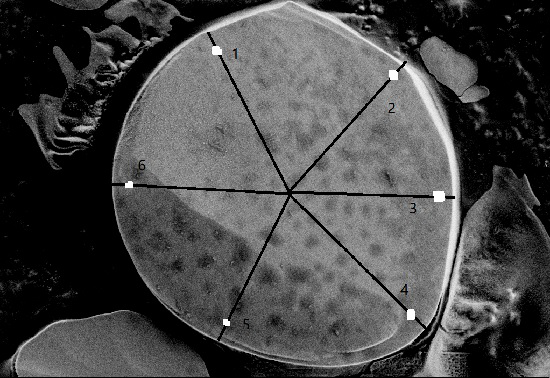

Image

Examples

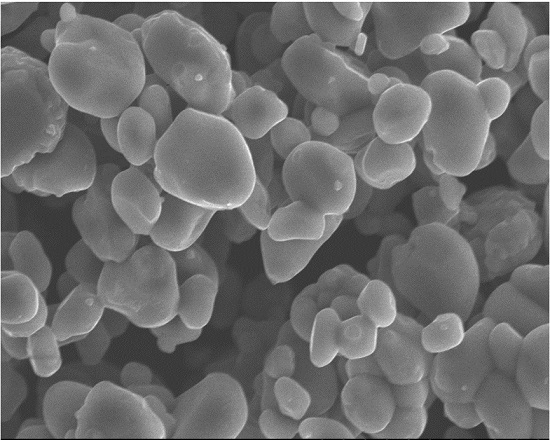

Embodiment 1

[0030] (1) NiSO 4 、CoSO 4 and MnSO 4 According to the molar ratio of Ni:Co:Mn=6:1:3, the mixed salt solution is formulated, the concentration of the mixed solution A is 2mol / L; the NaOH solution with a concentration of 5mol / L is used as a precipitant; the prepared concentration is 6mol / L The ammonia solution is used as a complexing agent; the mixed salt solution, NaOH solution and ammonia solution are continuously added to the stirred reaction vessel with a metering pump, the reaction temperature is kept at 40 °C, the pH is kept at 11, and the stirring speed is 500 r / min , the whole process of the reaction is protected by an inert gas; after the reaction, the obtained precipitate is filtered, washed, and dried at 110°C for 4-12h to obtain a Ni with a D50 of 3.5 microns 0.6 co 0.1 mn 0.3 (OH) 2 Precursor (NCM613 precursor).

[0031] Lithium carbonate and prepared Ni 0.6 co 0.1 mn 0.3 (OH) 2Weigh 1.07kg of lithium carbonate and 2.5kg of NCM613 precursor based on a mola...

Embodiment 2

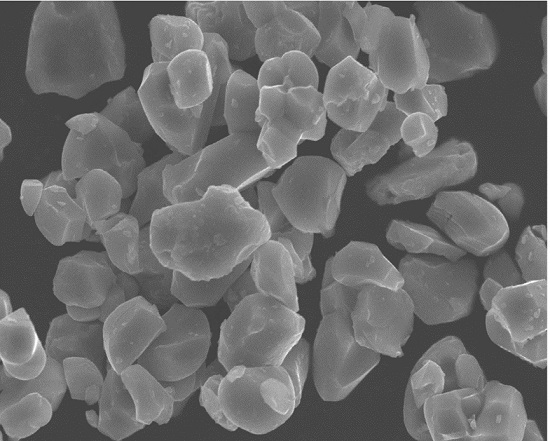

[0047] Mix 0.96kg of nano-scale metal Ni, 0.16kg of nano-metal Co and 0.45kg of nano-metal Mn in a high-speed mixer at 3000rpm for 3 minutes, then add 1.07kg of lithium carbonate, and continue mixing at 3000rpm for 8 minutes. Check that the materials have no white spots, and the mixing is complete. Put the mixed material into a 330*300*100mm alumina ceramic sagger, flatten the material, and use a cutter to evenly cut the material into 36 pieces, then put it into the atmosphere box furnace, and feed 60L / min of pure oxygen, the heating rate is 3°C / min, the temperature is raised to the first sintering temperature of 970°C and kept for 12h, and then naturally cooled. The cooled material is crushed into a crushed material smaller than 2mm by a double pair of rollers, and then the crushed material is crushed and classified by a jet mill to obtain a conventional single crystal 613 positive electrode material with a D50 of 3.8 microns. Subsequent preparation method is the same as tha...

Embodiment 3

[0049] The conventional single crystal 613 cathode material 1.5kg and 118g nanometer Co(OH) obtained in step (2) of Example 1 2 1.5kg of conventional single crystal 613 cathode material and 118g of nanometer Co(OH) obtained by "changed to" 2 and 2.8g nano-Al 2 o 3 ", other with embodiment 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com