Emulsion for inorganic silicate coating and preparation method thereof

An inorganic silicate and coating technology, applied in the direction of alkali metal silicate coatings, etc., can solve the problems of poor emulsion adaptability, poor storage stability, etc., and achieve the advantages of less emulsion consumption, less scrub resistance drop, and low film forming temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

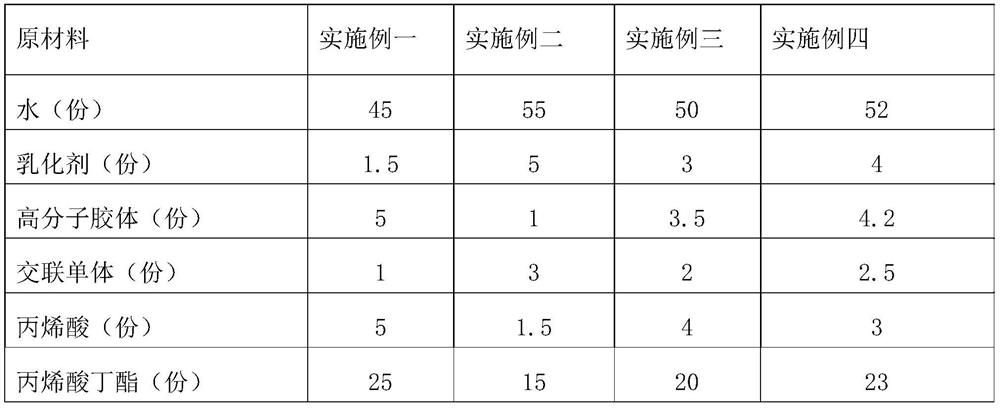

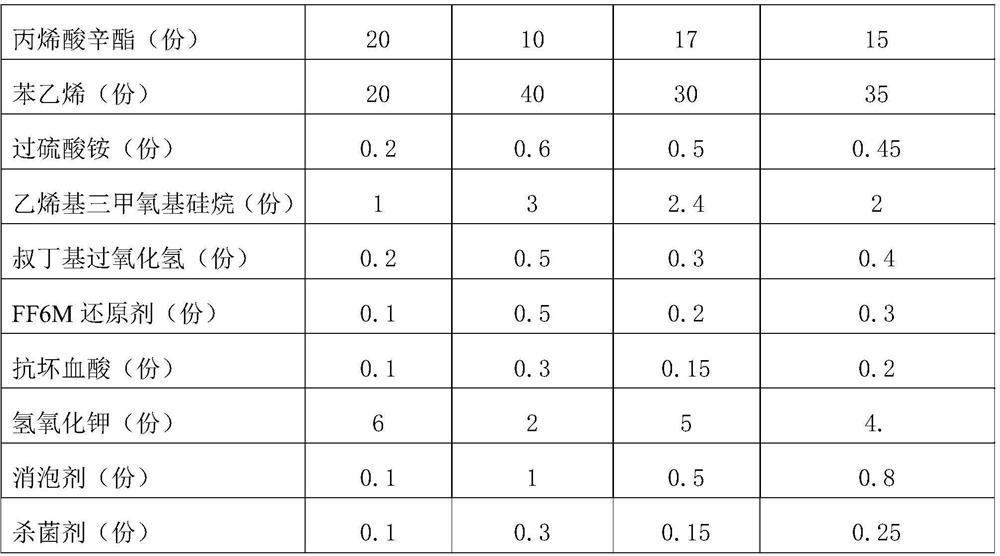

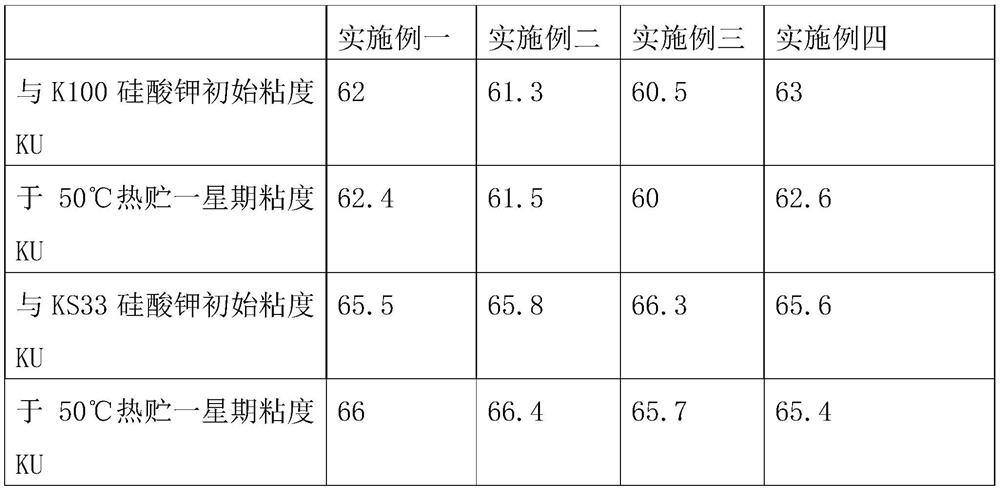

Examples

preparation Embodiment 1

[0065] A preparation method for preparing an emulsion for inorganic silicate paint in Example 1, comprising the following steps:

[0066] Step S01, prepare pre-emulsion in the monomer bottle: rinse with 15 parts of water, 1 part of emulsifier, 1 part of crosslinking agent, 5 parts of acrylic acid, 25 parts of butyl acrylate, 20 parts of octyl acrylate, and 20 parts of styrene Add water to the monomer bottle for emulsification in order;

[0067] Configure three parts of initiator aqueous solution, the first initiator aqueous solution, the second initiator aqueous solution and the third initiator aqueous solution, and the second initiator aqueous solution is packed in the oxidant bottle;

[0068] The second initiator aqueous solution is a mixed solution of 5 parts of water and 0.1 part of ammonium persulfate.

[0069] The first initiator aqueous solution is the aqueous solution of 0.08 part of ammonium persulfate;

[0070] The third initiator aqueous solution is the aqueous so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com