A low-temperature solid oxide fuel cell and its preparation method

A solid oxide and fuel cell technology, applied in solid electrolyte fuel cells, fuel cells, circuits, etc., can solve the problems of less application of SOFC electrolyte and no technical realization, etc., achieve excellent mechanical strength, optimize efficient use, and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

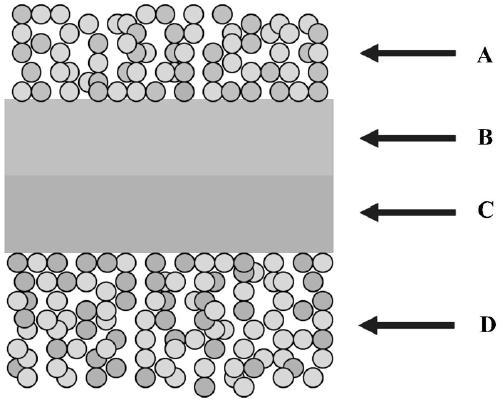

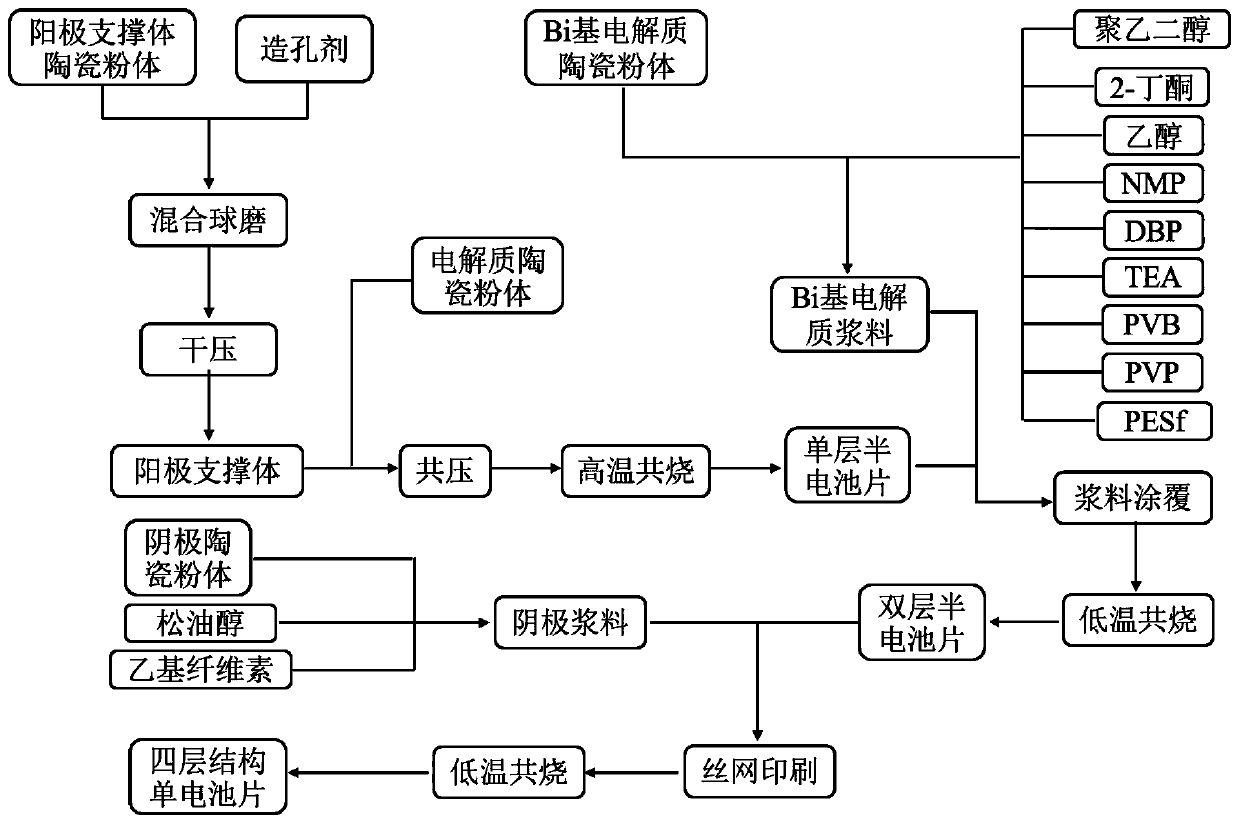

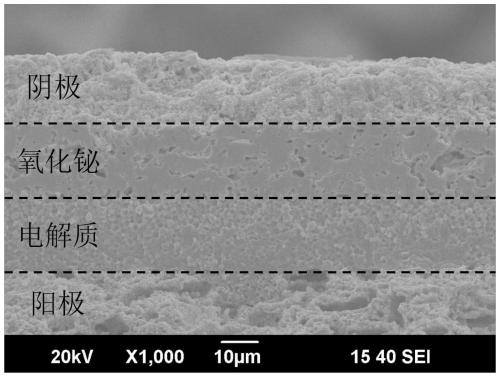

[0041] The present invention also provides a method for preparing the above-mentioned low-temperature solid oxide fuel cell, comprising the following steps: S1) mixing the anode support material with a pore-forming agent, and pressing and molding to obtain an anode support precursor; S2) in the A dense electrolyte layer is prepared on the anode support body precursor, and an anode support body provided with a dense electrolyte layer is obtained after sintering at a high temperature; the dense electrolyte layer is a cerium-based electrolyte layer or a zirconium-based electrolyte layer; S3) the bismuth oxide-based electrolyte slurry Coating on the dense electrolyte layer of the anode support provided with a dense electrolyte layer, after co-firing at a low temperature, an anode support provided with a bismuth oxide-based dense electrolyte layer and a dense electrolyte layer is obtained; S4) the anode support provided with The bismuth oxide-based dense electrolyte layer and the an...

Embodiment 1

[0055] The electron-conducting phase NiO powder of the anode support layer is obtained by decomposing basic nickel carbonate at 600°C, its particle size D50=0.4μm, and the ion-conducting phase Sm 0.075 N d0.075 Ce 0.85 o 2-δ Obtained by citrate combustion method (SNDC, powder treated in air at 700°C for 3h), its particle size D50=0.4μm.

[0056]Mix the above-mentioned NiO and SNDC mixed powders for the anode support layer at a volume ratio of 60:40, add starch with a mass fraction of 20%, ball mill in ethanol for 10 hours to mix evenly, and obtain starch-containing NiO-SNDC mixed powders after drying.

[0057] Take an appropriate amount of starch-containing NiO-SNDC mixed powder, and dry press it to obtain an anode support ceramic green body with a thickness of about 900 μm; use the same method to take an appropriate amount of loose SNDC powder obtained by the citrate combustion method, and co-press it to obtain a ceramic green body of about 900 μm. A 20 μm thick SNDC film ...

Embodiment 2

[0066] The electron conduction phase NiO powder preparation method of the anode support layer is the same as that of Example 1, the ion conduction phase G 0.1 Ce 0.9 o 2-δ Obtained by citrate combustion method (GDC, powder treated in air at 800°C for 3h, particle size D50=0.5μm).

[0067] The anode support layer NiO and GDC mixed powder were mixed according to the volume ratio of 60:40, 20% starch was added by mass fraction, mixed uniformly by ball milling in ethanol for 10 hours, and the NiO-GDC mixed powder containing starch was obtained after drying.

[0068] Take an appropriate amount of starch-containing NiO-GDC mixed powder, and dry press it to obtain an anode support ceramic green body with a thickness of about 900 μm; take an appropriate amount of loose GDC powder obtained by the citrate combustion method, and co-press to obtain a GDC film with a thickness of about 15 μm , to obtain a NiO-GDC|GDC double-layer half-cell green body, which was co-fired at 1400 ° C for 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com