Method for preventing high-temperature two-explosion of gas high-energy impulse dusting device

A high-energy pulse and air curtain technology, applied in the direction of combustion method, heating method, solid residue removal, etc., can solve the problems of not achieving good effect of ash removal, 2 noises, and reduced working energy, and achieve the effect of reducing adverse interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

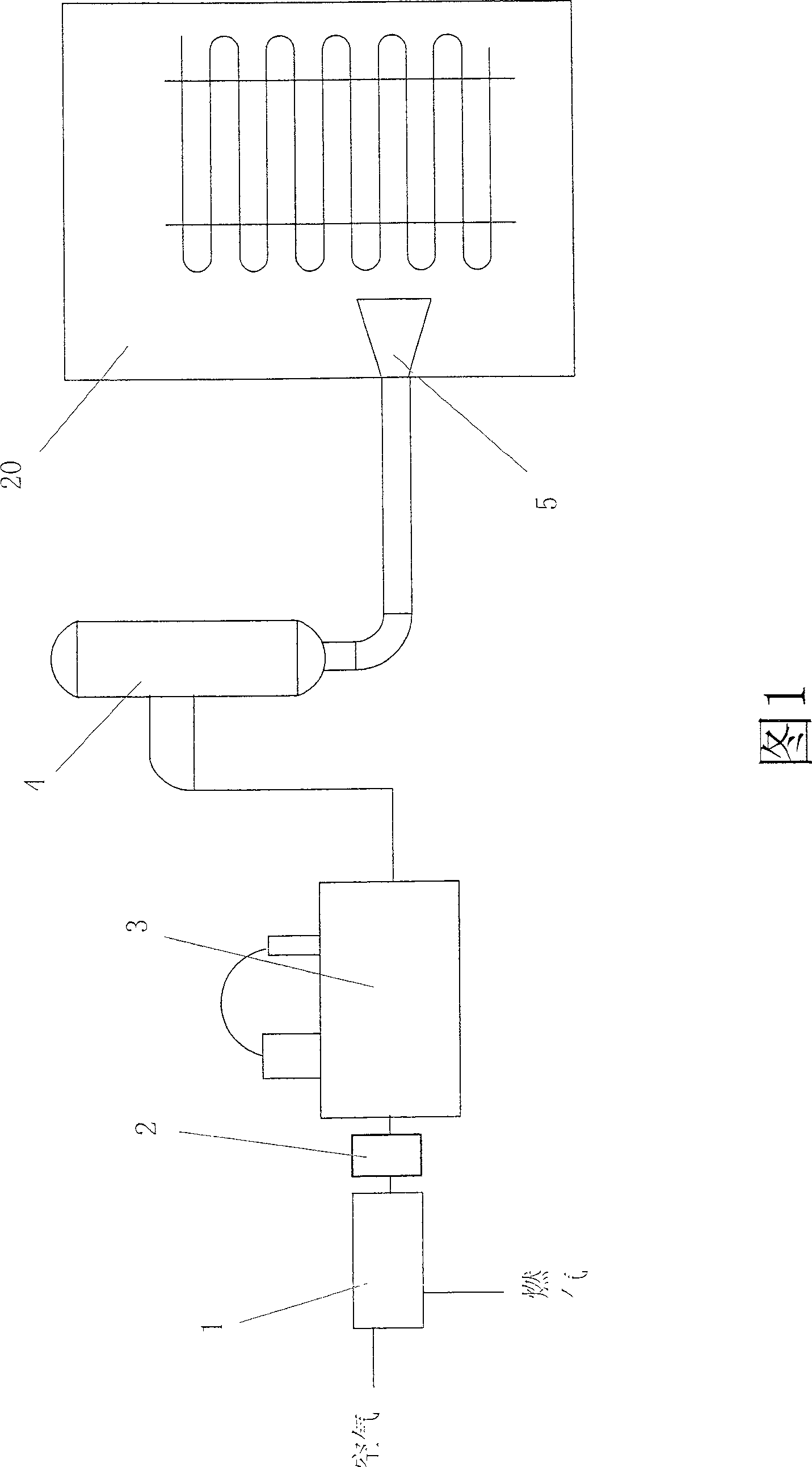

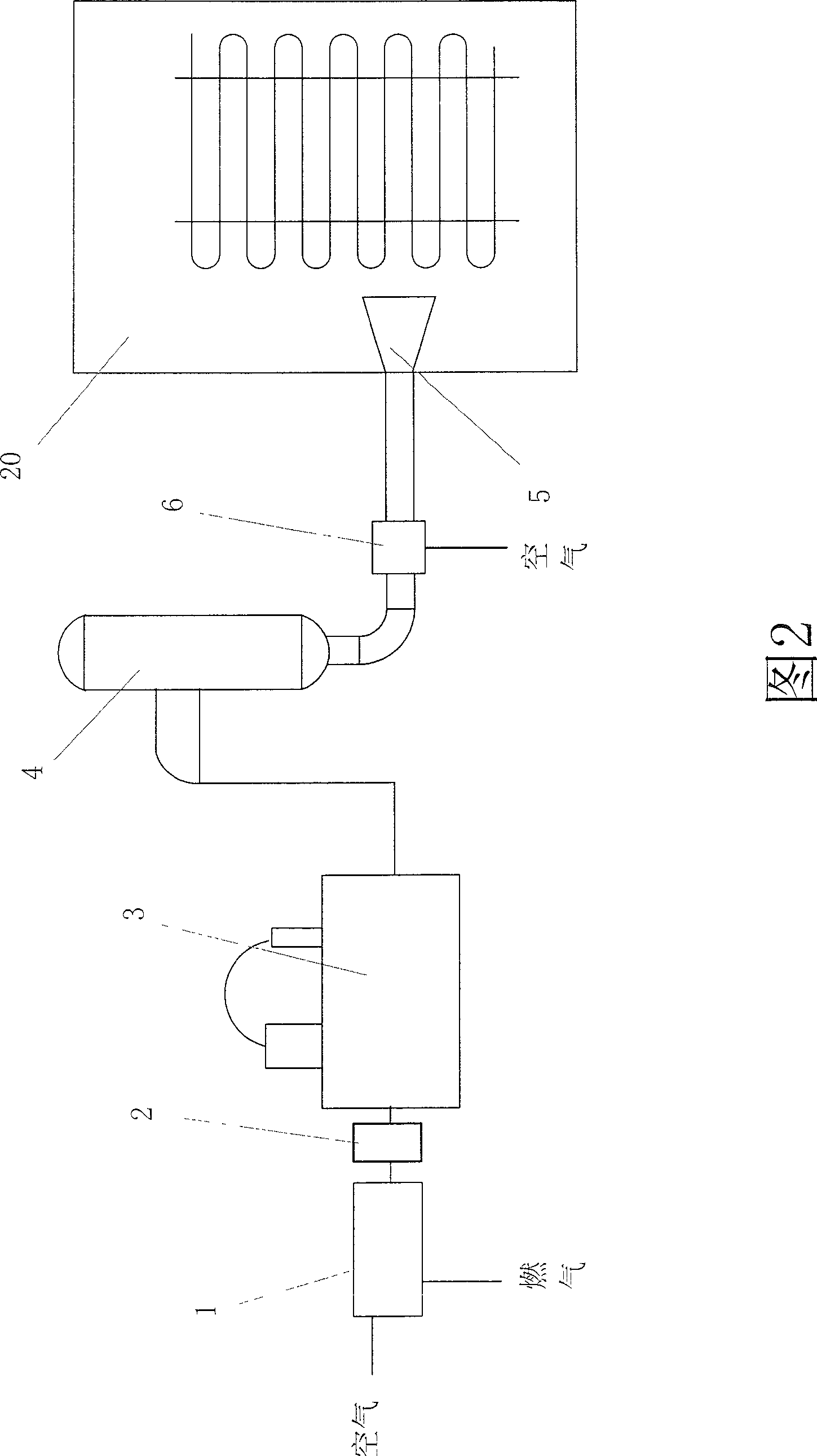

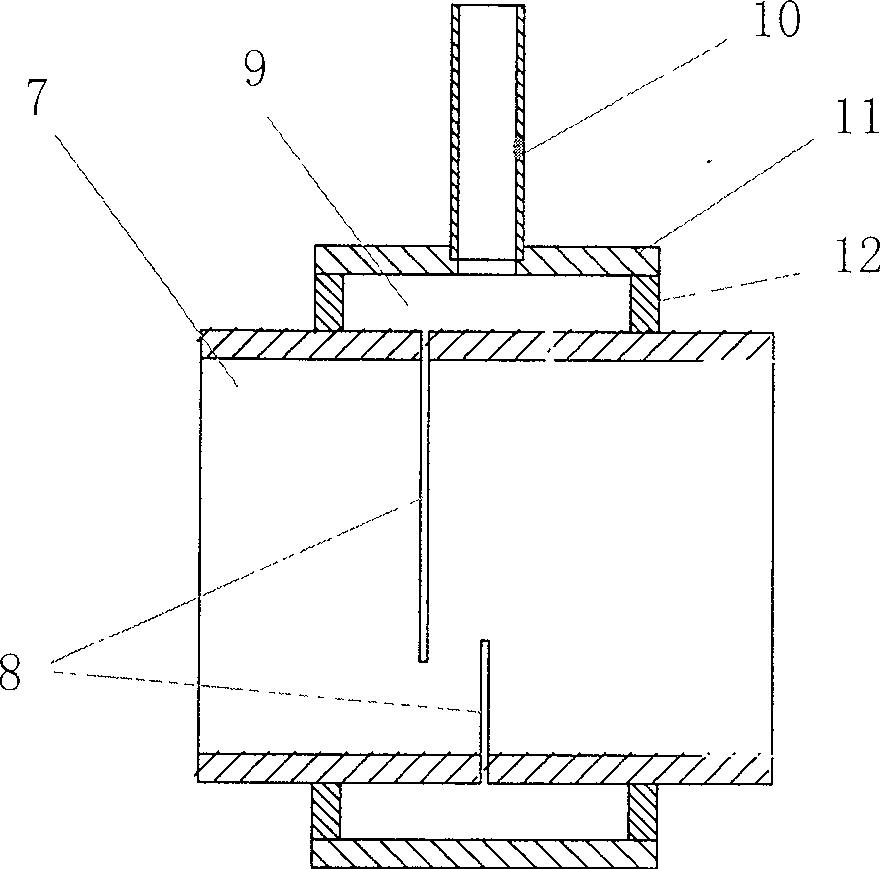

[0026] The present invention prevents the gas high-energy pulse ash removal device from working under high temperature conditions, the mixed gas contacts with high temperature flue gas, or is subjected to high temperature radiation, causing the ash removal device to ignite in advance, and the phenomenon of double ringing occurs, which reduces the working energy and cannot reach In order to improve the good effect of dust removal, a method to prevent second ringing is proposed. The gas-fired high-energy pulse ash removal device is composed of a mixing tank, a tempering prevention tank, an ignition tank, a pulse tank and a pulse nozzle. Analysis of the reason why the second ringing will affect the working energy lies in the pre-ignition, that is, before a certain proportion of combustible gas mixture is completely filled with each container in the ash removal device, it is ignited at the pulse nozzle, which cannot make the pulse tank mix The fullness and pressure of the gas reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com