Anti-blocking super-critical water oxidation reactor

A supercritical water oxidation and reactor technology, applied in the oxidation water/sewage treatment and other directions, can solve the problems of easy clogging, low safety performance, poor stability, etc., to reduce clogging, simplify the manufacturing process, and solve the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific embodiments. It should be understood that the following examples are only used to illustrate the present invention and not to limit the scope of the present invention.

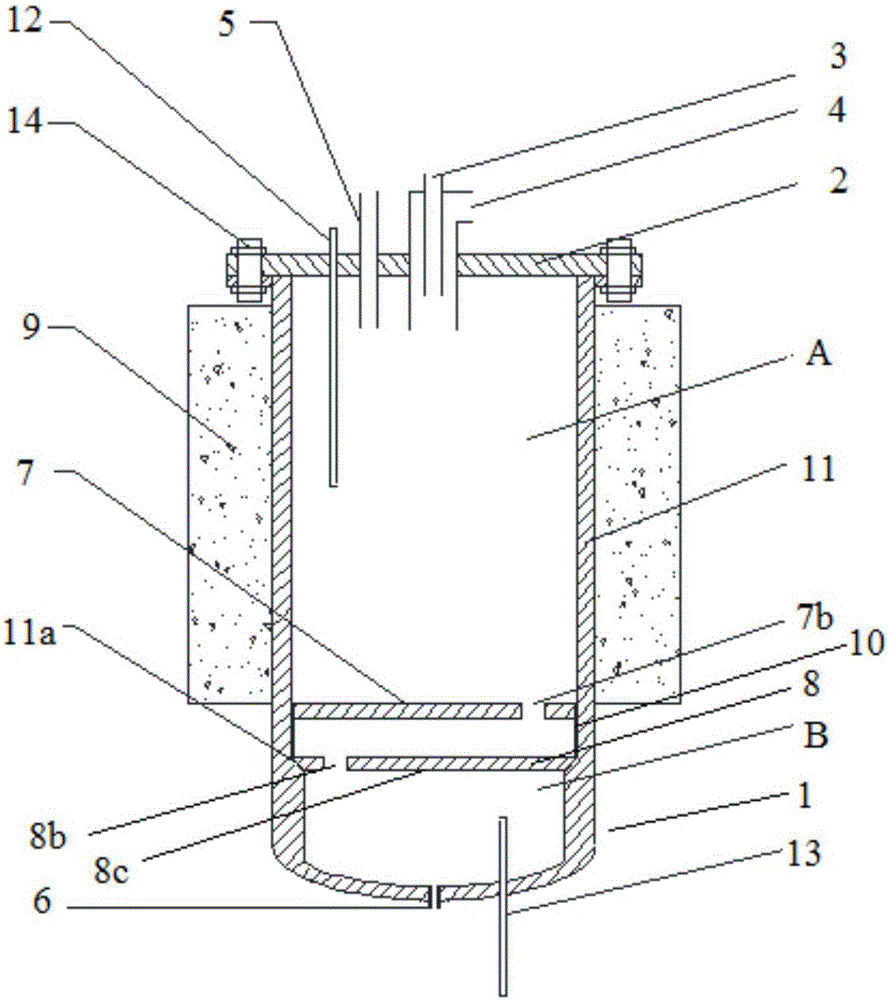

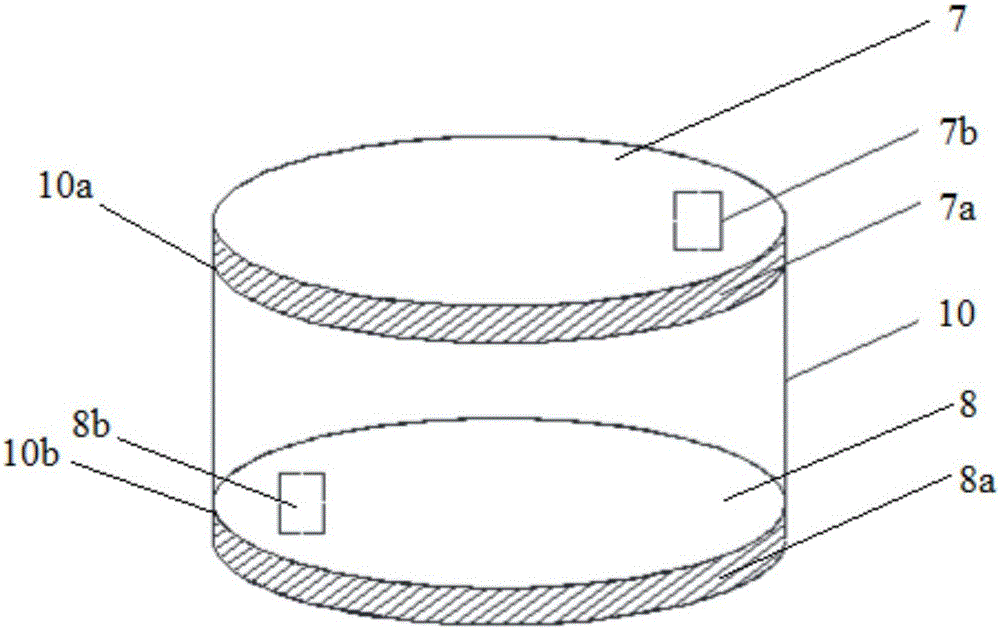

[0026] Such as figure 1 Shown is a supercritical water oxidation reactor according to a preferred embodiment of the present invention. The supercritical water oxidation reactor mainly includes: a reactor cylinder 1, a reactor cylinder cover 2, an organic feed port 3, and an oxidant feed The material inlet 4, the water inlet 5, the reaction product outlet 6, and two partitions 7 and 8 horizontally extending inside the reactor cylinder 1, and a heating jacket 9. Among them, the reactor cylinder body 1 and the reactor cylinder cover 2 are fixed by fastening bolts 14 to form a closed container. The organic material feed port 3, the oxidant feed port 4, and the water inlet 5 are all set on the reactor cylinder cover 2, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com