Lithium battery electrode and preparation method and application thereof

A lithium battery and electrode technology, applied in the field of energy storage, can solve problems such as the safety and stability of lithium batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

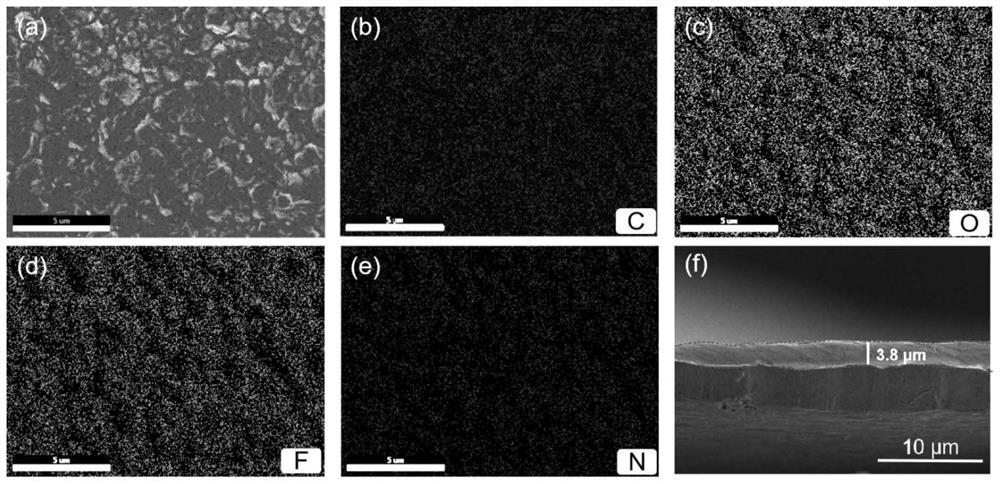

[0031] A method for preparing a lithium metal negative electrode with uniform lithium ion distribution artificial SEI, comprising the following steps:

[0032] Step 1, synthesis of TAPT-DHTA-COF: 2-4,6-tris(4-aminophenyl)-1,3,5-triazine and 2,5-dihydroxy-1,4-benzenedicarbaldehyde According to the molar ratio of 1:(1~2), preferably 1:1-1:1.5, suspended in anhydrous N,N-dimethylformamide solution under nitrogen atmosphere, 2-4,6-tri( The total molar amount of 4-aminophenyl)-1,3,5-triazine and 2,5-dihydroxy-1,4-benzenedicarbaldehyde and the volume ratio of anhydrous N,N-dimethylformamide solution 5mmol: (15-20)mL, heat and reflux at >120°C for 8-15h, cool to room temperature, filter the crude product, wash with N,N-dimethylformamide and ethanol to obtain a red powder, which is TAPT -DHTA-COF;

[0033] Step 2, the synthesis of Nafion-Li: LiOH·H 2 O added (5wt%) Nafion solution, LiOH·H 2 The molar ratio of O and Nafion solution is 1:1, and the lithiation is completed under vigo...

Embodiment 1

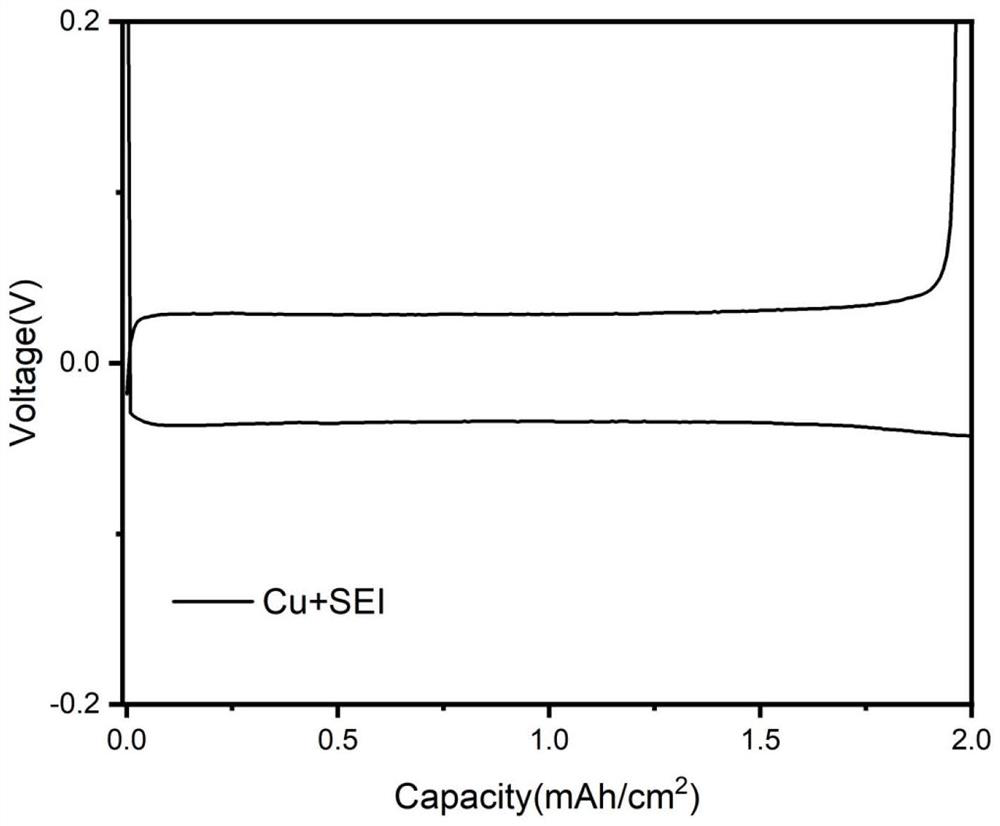

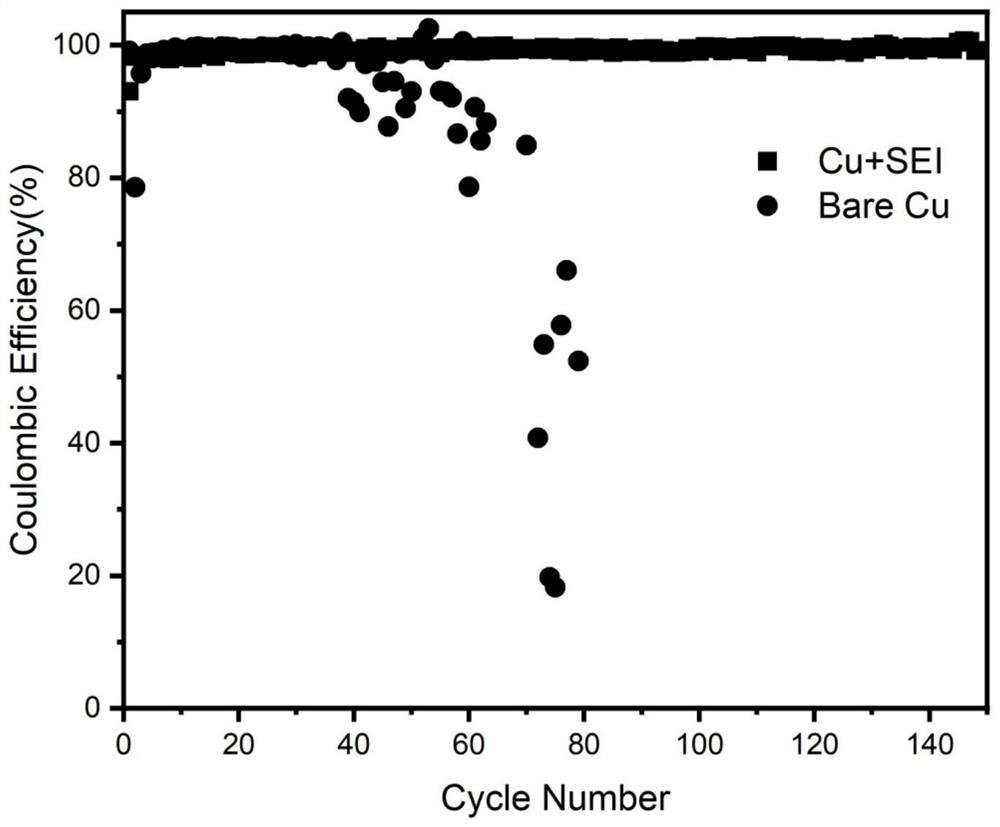

[0042] A method for preparing a lithium battery negative electrode with uniform lithium ion distribution artificial SEI layer, comprising the following preparation steps:

[0043] 1) Synthesis of TAPT-DHTA-COF: 2-4,6-tris(4-aminophenyl)-1,3,5-triazine (0.71g, 2.00mmol) and 2,5-dihydroxy-1 , 4-Phenylenedicarbaldehyde (0.42 g, 3.00 mmol) was suspended in anhydrous N,N-dimethylformamide solution (15 mL) under nitrogen atmosphere. The mixture was refluxed for 12 hours at 130°C. After cooling to room temperature, the crude product was filtered and washed with N,N-dimethylformamide and ethanol to obtain a red powder;

[0044] 2) Synthesis of Nafion-Li: Add 25.2mg LiOH·H2O into 10mL Nafion suspension (5wt%), stir vigorously at 100°C for 6h to complete lithiation. Then, the Nafion-Li solution was frozen with liquid nitrogen for 10 minutes until the freezing was complete, and then the sample was placed in a freeze dryer and freeze-dried for 12 hours under negative atmospheric pressur...

Embodiment 2

[0057] A method for preparing a lithium battery negative electrode with uniform lithium ion distribution artificial SEI layer, comprising the following preparation steps:

[0058] 1) Synthesis of TAPT-DHTA-COF: 2-4,6-tris(4-aminophenyl)-1,3,5-triazine (0.71g, 2.00mmol) and 2,5-dihydroxy-1 , 4-Phenylenedicarbaldehyde (0.42 g, 3.00 mmol) was suspended in anhydrous N,N-dimethylformamide solution (15 mL) under nitrogen atmosphere. The mixture was refluxed for 8 hours at 130°C. After cooling to room temperature, the crude product was filtered and washed with N,N-dimethylformamide and ethanol to obtain a red powder;

[0059] 2) Synthesis of Nafion-Li: 25.2mg LiOH·H 2 O was added to 10 mL of Nafion suspension (5 wt %), and vigorously stirred at 100 °C for 6 h to complete lithiation. Then, the Nafion-Li solution was frozen with liquid nitrogen for 10 minutes until the freezing was complete, and then the sample was placed in a freeze dryer and freeze-dried for 12 hours under negativ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com