Three-dimensional spherical silicon-carbon composite negative electrode material and preparation method therefor

A silicon-carbon composite and anode material technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of insufficient initial efficiency and cycle life, and achieve excellent cycle and rate performance, high specific capacity, and reduced ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

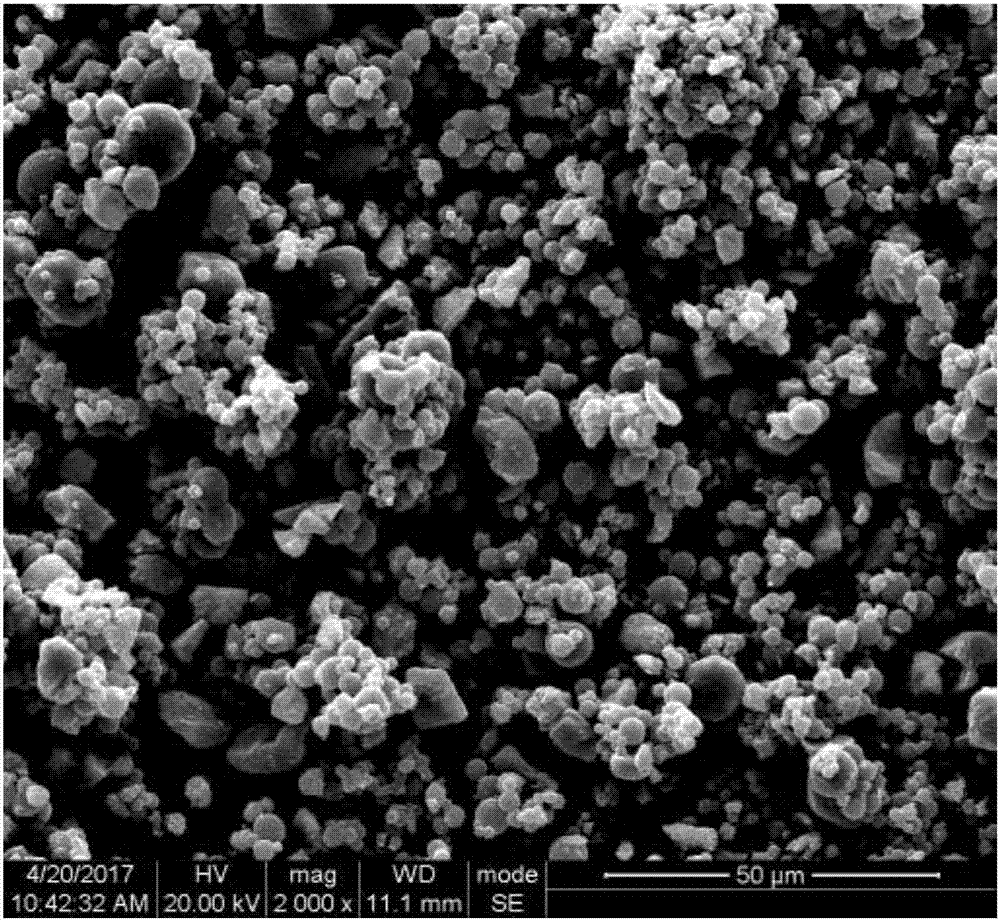

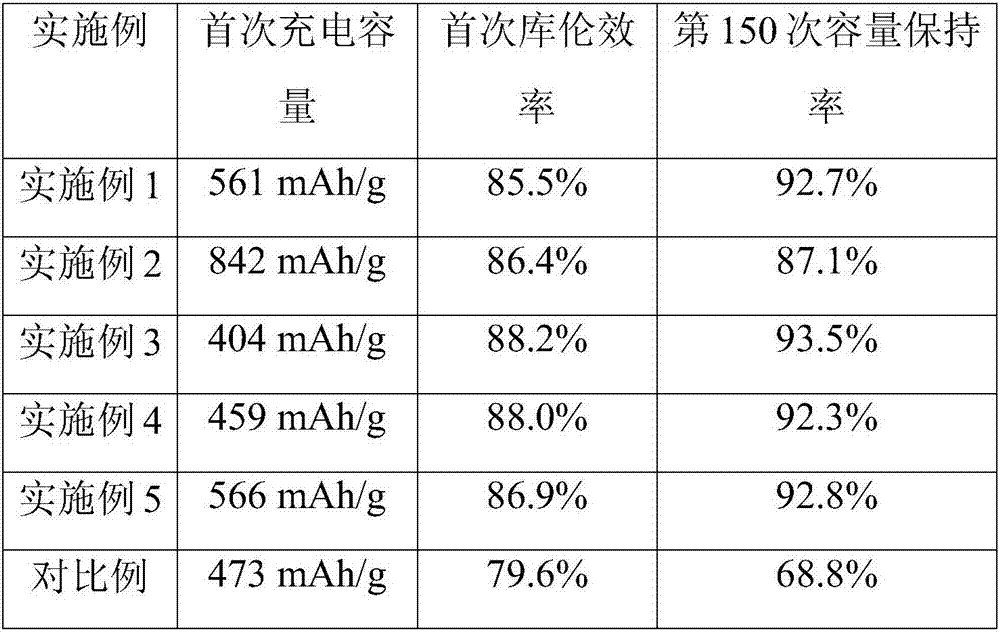

[0028] At room temperature, disperse 1g of nano-silicon with a particle size of 50-100nm in a mixture of 50mL of ethanol and water, the volume ratio of ethanol to water is 5:1, and then add 1g of phenolic resin and 0.5g of ten Hexaalkyltrimethylammonium bromide, and then electromagnetically stir the mixed solution at a speed of 200rpm for 60min; the resulting solution is spray-dried, the spray drying inlet air temperature is 170°C, the outlet air temperature is 100°C, and the feed rate is 5mL / min, the Si@C precursor is obtained; in an argon atmosphere, the Si@C precursor is heated to 700°C at a heating rate of 10°C / min, and sintered at 700°C for 3h, and the Si @C material; disperse 0.2g of Si@C material and 1g of graphite in a mixture of 60mL of ethanol and water, the volume ratio of ethanol to water is 5:1, and then add 0.06g of sodium lauryl sulfate to the mixture and 0.12g of phenolic resin, and the mixed solution was electromagnetically stirred at 120rpm for 60min; the res...

Embodiment 2

[0030] At room temperature, disperse 1g of nano-silicon with a particle size of 30-50nm in a mixture of 150mL of ethanol and water, the volume ratio of ethanol to water is 5:1, and then add 2g of phenolic resin and 1g of dodecane to the mixture. Sodium alkylbenzene sulfonate, then electromagnetically stir the mixed solution at a speed of 180rpm for 120min; the resulting solution is spray-dried, the spray-drying inlet air temperature is 250°C, the outlet air temperature is 120°C, and the feed rate is 8mL / min. The Si@C precursor was obtained; under a nitrogen atmosphere, the Si@C precursor was heated to 900°C at a heating rate of 2°C / min, and sintered at 900°C for 5 hours to obtain a Si@C material; 0.5g of Si@C material and 0.5g of graphite were dispersed in a mixture of 150mL of ethanol and water, the volume ratio of ethanol to water was 4:1, and then 1g of polyvinylpyrrolidone and 1g of phenolic resin were added to the mixture, and the speed was 200rpm Electromagnetically stir...

Embodiment 3

[0032]At room temperature, disperse 1g of nano-silicon with a particle size of 150-200nm in a mixture of 200mL of ethanol and water, the volume ratio of ethanol to water is 1:2, and then add 5g of glucose and 2g of carboxymethyl to the mixture Sodium cellulose, and then electromagnetically stirred the mixed solution at a speed of 120rpm for 80min; spray-dried the obtained solution, the spray-drying inlet air temperature was 220°C, the outlet air temperature was 110°C, and the feed rate was 15mL / min to obtain Si @C precursor; in an argon atmosphere, the Si@C precursor was heated to 800 °C at a heating rate of 5 °C / min, and sintered at 800 °C for 3 hours to obtain a Si@C material; 0.25 g The Si@C material and 0.75g graphite were dispersed in a mixture of 100mL ethanol and water, the volume ratio of ethanol and water was 1:2, and then 0.4g sodium alginate and 0.5g polyvinyl alcohol were added to the mixture, at 180rpm The rotating speed electromagnetically stirred the mixed solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com