Composite positive electrode material of lithium ion battery and preparation method of composite positive electrode material

A composite positive electrode material and lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of material surface structure damage, inability to provide coating means circulation, safety issues, and difficulty in industrial production, etc., to achieve improvement Processability, reduced alkali content, reduced direct contact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) Add 10.76g of ferric chloride and 8.76g of diammonium hydrogen phosphate into 132g of water and dissolve to obtain a transparent solution, and 100g of ternary material (LiNi 0.6 co 0.2 mn 0.2 o 2 ) into absolute ethanol to prepare a suspension with a solid content of 20%, and then add the solution to the suspension to obtain a slurry;

[0043] 2) Spray-dry the slurry obtained above, and control the outlet temperature at 100° C.; heat-treat the spray-dried material at 800° C. for 2 hours in an air atmosphere to obtain a ternary material coated with iron phosphate;

[0044] 3) using a three-dimensional mixer to mix the above-mentioned ternary material coated with iron phosphate, 2.33g lithium carbonate, and 0.55g rock sugar evenly to obtain an intermediate product;

[0045] 4) Sinter the above-mentioned intermediate product at 700°C for 5 hours in a nitrogen atmosphere to obtain a lithium-ion battery composite positive electrode material, the chemical formula is LiN...

Embodiment 2

[0053] 1) 7.9g (nonahydrate) ferric nitrate and 2.25g ammonium dihydrogen phosphate were added to 489g water to dissolve to obtain a transparent solution, and 100g ternary material (LiNi 0.8 co 0.1 mn 0.1 o 2 ) into absolute ethanol to prepare a suspension with a solid content of 70%, and then add the solution to the suspension to obtain a slurry;

[0054] 2) Perform rotary evaporation and drying on the slurry obtained above, and heat-treat the dried material at 350° C. for 20 hours in an air atmosphere to obtain a ternary material coated with iron phosphate;

[0055] 3) using a three-dimensional mixer to mix the above-mentioned ternary material coated with iron phosphate, 0.23g lithium carbonate, and 0.8g polyethylene glycol to obtain an intermediate product;

[0056] 4) Sinter the above-mentioned intermediate product at 400°C for 20 hours in a carbon dioxide atmosphere to obtain a composite positive electrode material for a lithium-ion battery, with the chemical formula L...

Embodiment 3

[0060] 1) Add 43.29g (nonahydrate) ferric nitrate and 43.02g ammonium phosphate to 265g water to dissolve to obtain a transparent solution, and 100g ternary material (LiNi 0.82 co 0.1 al 0.08 o 2 ) into water to prepare a suspension with a solid content of 40%, and then add the solution to the suspension to obtain a slurry;

[0061] 2) Spray-dry the slurry obtained above, and heat-treat the dried material at 600° C. for 1 hour in an air atmosphere to obtain a ternary material coated with iron phosphate;

[0062] 3) using a ball mill to uniformly mix the above-mentioned ternary material coated with iron phosphate, 10.57g (monohydrate) lithium hydroxide, and 11g glucose to obtain an intermediate product;

[0063] 4) Sinter the above intermediate product at 600°C for 10 h in an argon atmosphere to obtain a lithium-ion battery composite positive electrode material with the chemical formula LiNi 0.82 co 0.1 al 0.08 o 2 0.0129FePO 3.9 0.2442LiFePO 4 .

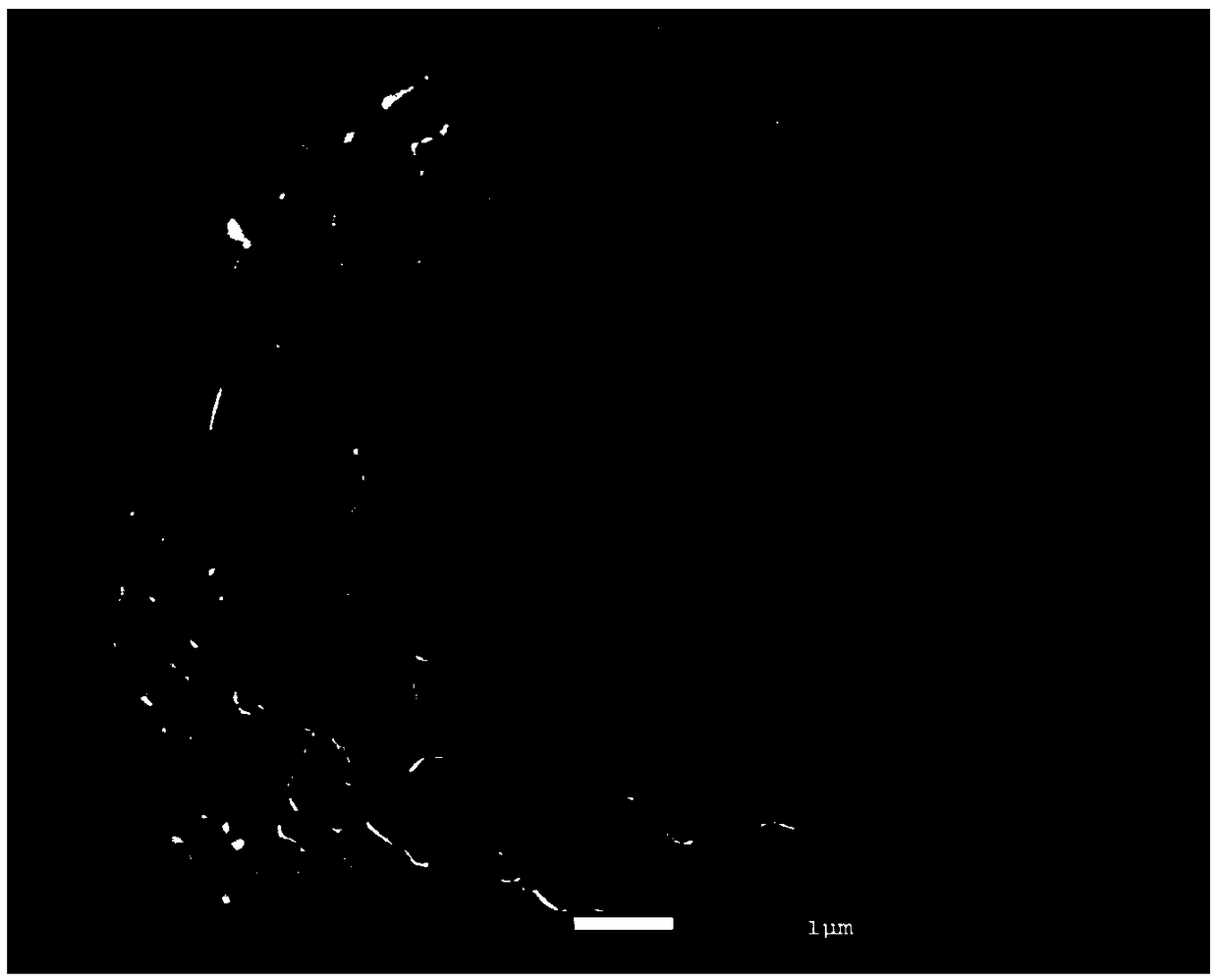

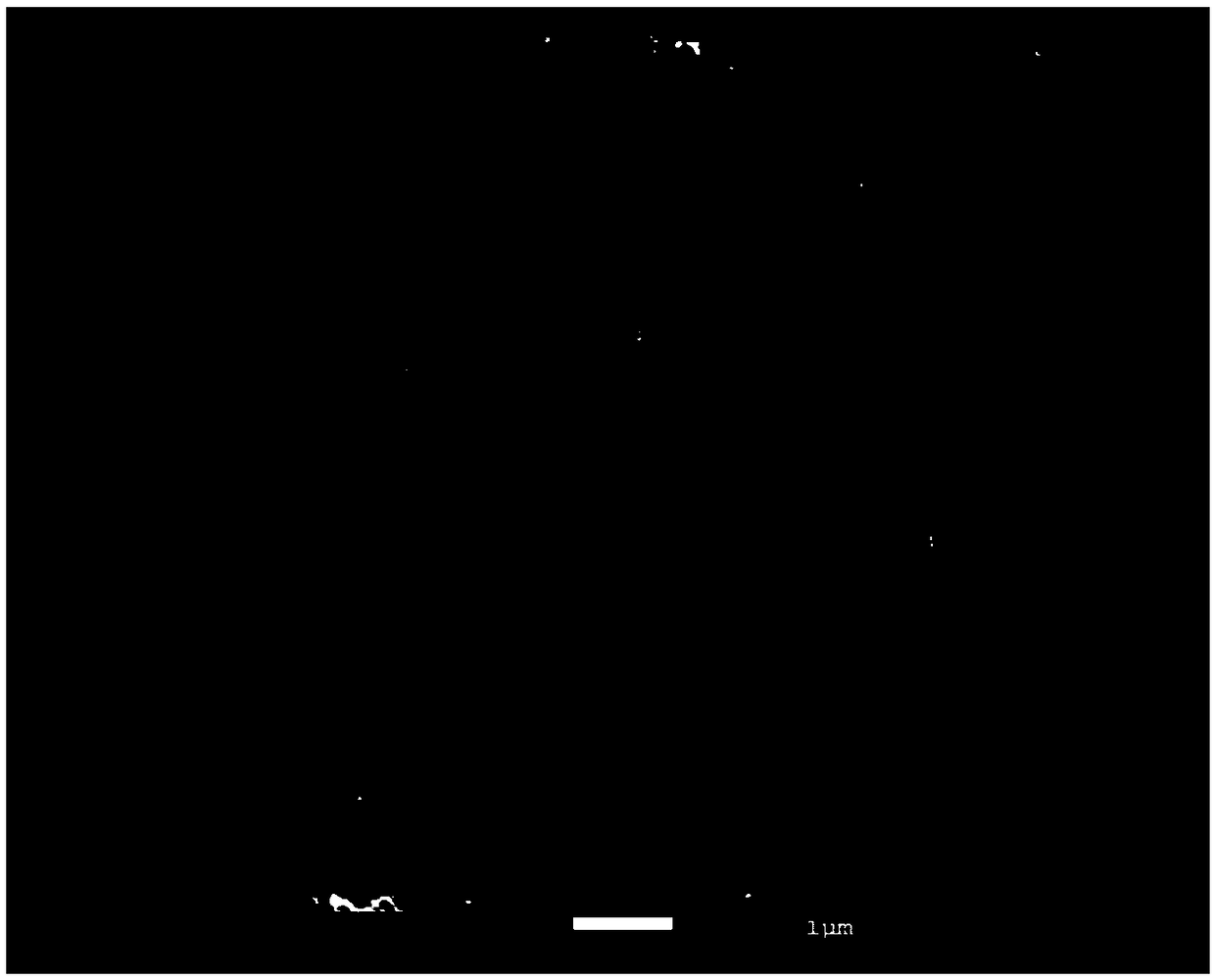

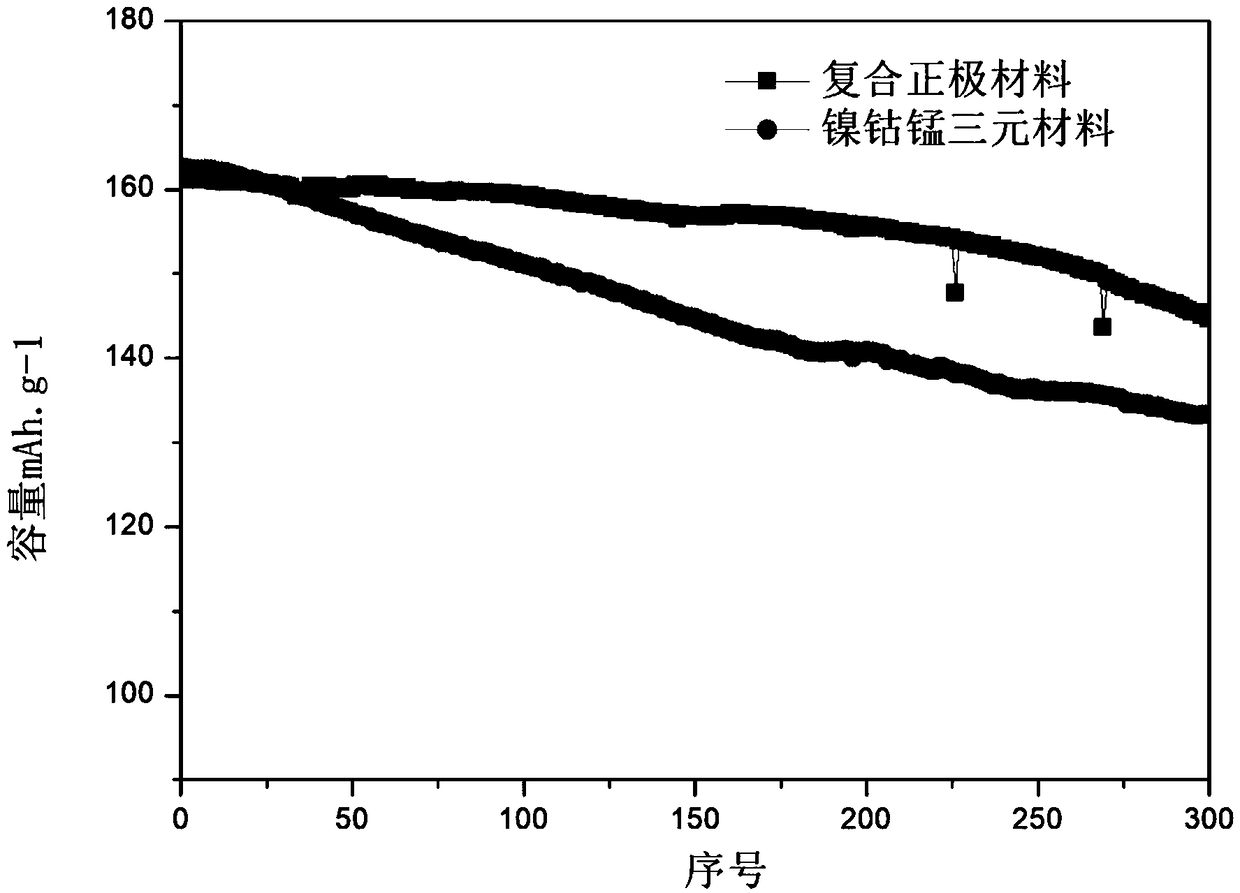

[0064] The ternary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com