A kind of lithium-ion battery composite cathode material and preparation method thereof

A composite cathode material, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as difficult industrial production, damage to the surface structure of materials, inability to provide coating means for circulation, and safety issues, and to reduce Alkali content, improved processability, reduced direct contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) Add 10.76 g of iron chloride and 8.76 g of sodium hydrogen phosphate to 132 g of water dissolved to obtain a transparent solution, 100 g of three-membered materials (Lini 0.6 CO 0.2 Mn 0.2 O 2 Add to anhydrous ethanol, formulated a suspension of 20%, and then adding the solution to the suspension to obtain a slurry;

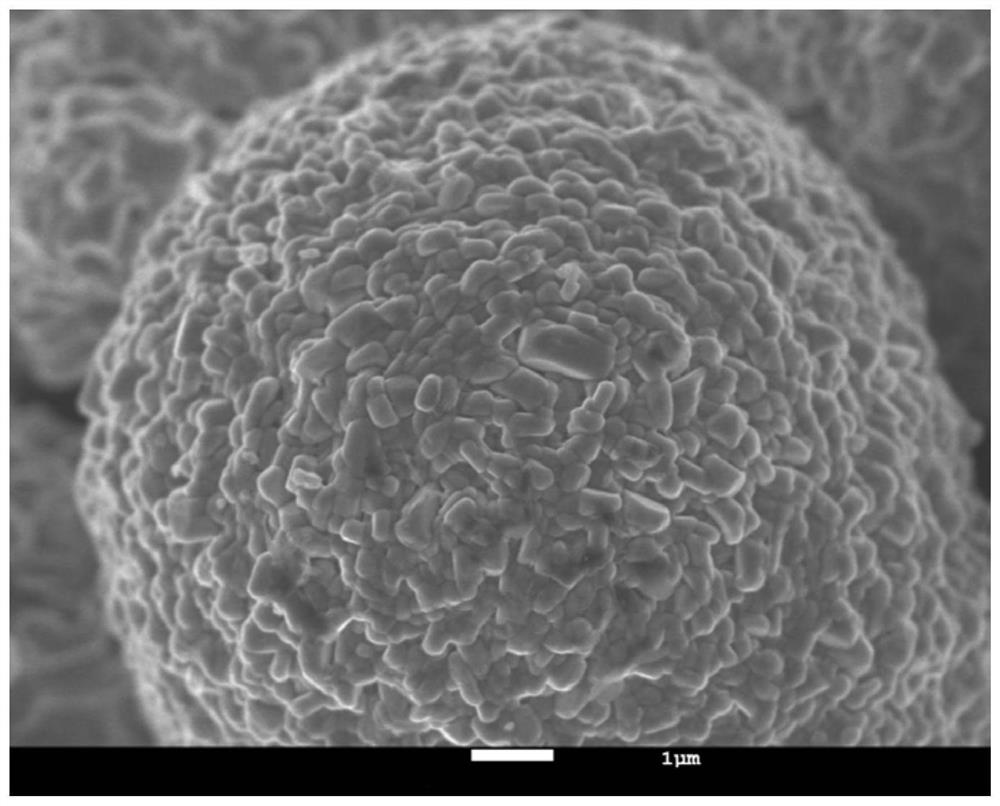

[0043] 2) The slurry obtained above is spray drying, controlling the air outlet temperature at 100 ° C; the material obtained by spray drying is heat treatment at 800 ° C in the air atmosphere for 2 h, i.e., the ternary material of the surface of the surface of iron is obtained;

[0044] 3) Use a three-dimensional mixer to cover the three-membered material of iron iron, 2.33 g of lithium carbonate, 0.55 g of rock sugar is mixed evenly;

[0045] 4) Sintering the above intermediate product 700 ° C in a nitrogen atmosphere to obtain a lithium ion battery composite positive material, the chemical formula is Lini 0.6 CO 0.2 Mn 0.2 O 2 0.0032FEPO 3.8 0.061lifepo ...

Embodiment 2

[0053] 1) 7.9 g (nine-water) nitrate iron and 2.25 g of phosphate is dissolved in 489 g of water to dissolve and dissolve the transparent solution, 100 g of three-membered materials (LINI) 0.8 CO 0.1 Mn 0.1 O 2 Add to anhydrous ethanol, formulated a suspension of 70%, and then adding the solution to the suspension to obtain a slurry;

[0054] 2) The above obtained slurry was rotationally evaporated, and the dried material was heat-treated at 350 ° C in the air atmosphere to obtain a tri-metallic material having iron phosphate.

[0055] 3) Use a three-dimensional mixer to cover the three-dimensional iron of iron iron, 0.23 g of lithium carbonate, 0.8 g of polyethylene glycol is mixed;

[0056] 4) Sintering the above-described middle carbon dioxide atmosphere for 20 hours to obtain a lithium ion battery composite positive material, the chemical formula is Lini 0.8 CO 0.1 Mn 0.1 O 2 · 0.0129fepo 4 0.0061Lifepo 4 .

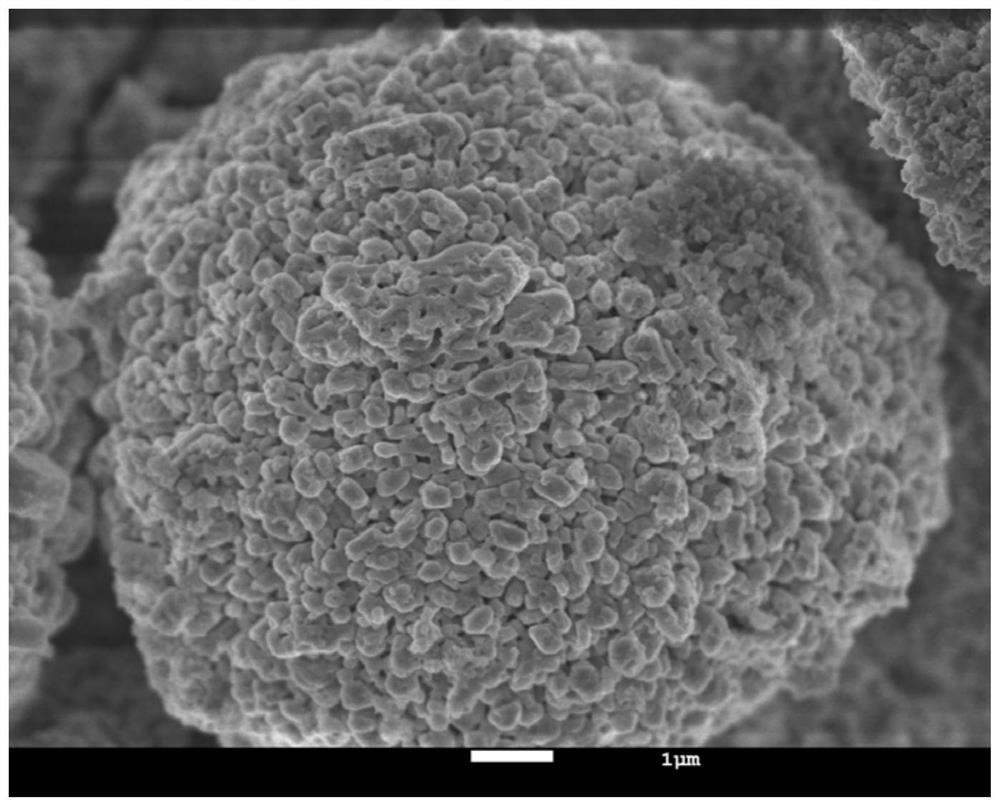

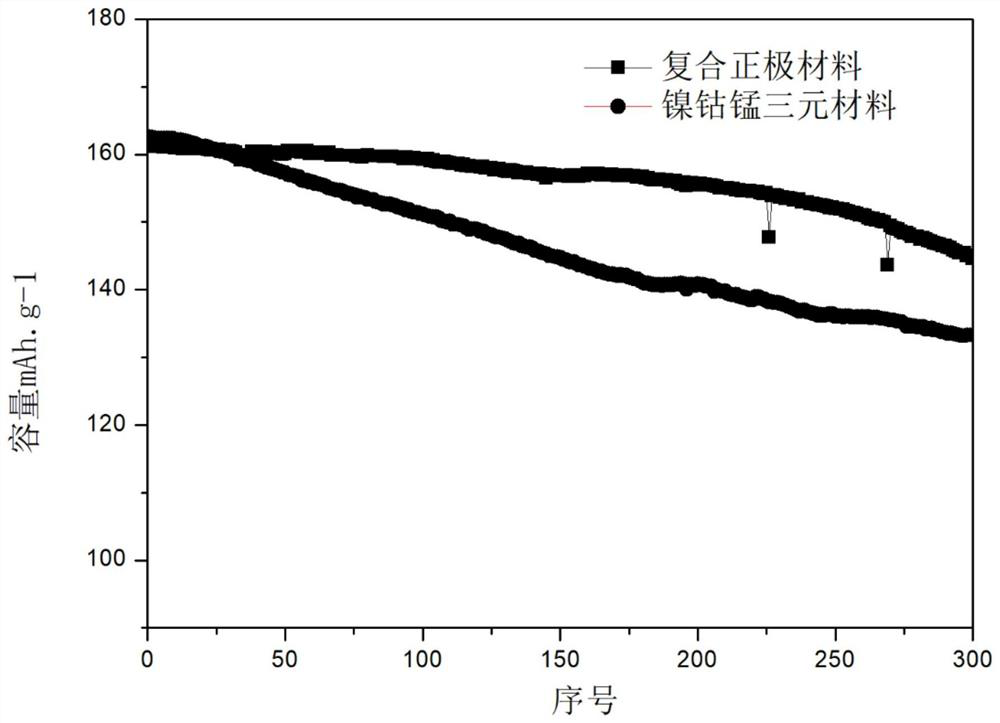

[0057] The three-membered material used for the use of the three-dim...

Embodiment 3

[0060] 1) 43.29 g (nine-water) nitrate iron and 43.02 g of ammonium phosphate were dissolved in 265 g of water dissolved to obtain a transparent solution, and 100 g of three-membered materials (Lini 0.82 CO 0.1 Al 0.08 O 2 Add to water, formulated a suspension of 40%, and then add solution to the suspension to obtain a slurry;

[0061] 2) The above obtained slurry is spray dried, and the material obtained by drying the dried 3 ° C is heat for 1 h in the air atmosphere, i.e., the ternary material of the surface of the surface.

[0062] 3) Use a ball mill to cover the three-membered material of iron iron, 10.57 g (a water) lithium hydroxide, 11 g of glucose mixing evenly;

[0063] 4) Sintering the above intermediate product at 600 ° C for 10 h in an argon atmosphere to obtain a lithium ion battery composite positive material, and the chemical formula is LINI. 0.82 CO 0.1 Al 0.08 O 2 · 0.0129fepo 3.9 0.2442lifepo 4 .

[0064] The cycle test of the three-membered material used and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com