Method for preparing water-soluble molecular self-assembly film type metal protective agent

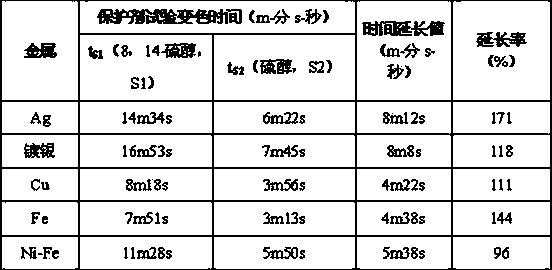

A technology of metal protective agent and self-assembled film, which is applied in the field of metal protective agent, can solve problems such as complicated use process, manufacturing cost, increased use cost, application limitation, etc., to achieve enhanced protection performance, extended protection time, and prolonged metal discoloration time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for preparing a water-soluble molecular self-assembled film type metal protective agent, the steps of which are:

[0046] A, the mass ratio is 0.5:10 namely 0.5kg tap water and 10kg organic solvent α-phenylmethyl-ω-[(1,1,3,3-tetramethylbutyl)phenoxy]-poly( Oxygen-1,2-ethylene) (TRITON for short) was mixed in the reaction kettle and stirred for 2 minutes to make a mixed solvent;

[0047] B, add the 30% emulsifying agent of step A gained mixed solvent quality, i.e. 3.15kg hydroxyethyl fatty acid propyl fat (HDP), stir 3 minutes, make mixture;

[0048] C, add the film-forming agent of 12% of the mass of the mixture obtained in step B, i.e. 1.638kg 8,14-dihydroxyoctadecyl mercaptan (D-SM), stir for 3 minutes, and further obtain a mixed solution;

[0049] D. Add 1.5% surfactant of the mass of the mixed solution obtained in step C, i.e. sodium dodecyl sulfate (SDS) 0.229kg and 0.1% reducing agent, i.e. vitamin C (ascorbic acid, referred to as VC or AA) 15.3g , heat...

Embodiment 2

[0053] A method for preparing a water-soluble molecular self-assembled film type metal protective agent, the steps of which are:

[0054] A. The mass ratio is 0.75:10, that is, 0.75kg of deionized water and 10kg of organic solvent α-phenylmethyl-ω-[(1, 1, 3, 3-tetramethylbutyl) phenoxy]- Poly(oxy-1,2-ethylene) (TRITON for short) was mixed in a reaction kettle and stirred for 3 minutes to make a mixed solvent;

[0055] B, add the emulsifying agent of 35% of the mixed solvent quality of step A gained, i.e. 3.76kg hydroxyethyl fatty acid propyl fat (HDP), stir 5 minutes, make mixture;

[0056] C, add the film-forming agent of 15% of the mass of the mixture obtained in step B, i.e. 2.18kg 8,14-dihydroxyoctadecyl mercaptan (D-SM), stir for 4 minutes, and further obtain a mixed solution;

[0057] D. Add 1.65% surfactant of the mass of the mixed solution obtained in step C, i.e. sodium dodecyl sulfate (SDS) 0.275kg and 0.2% reducing agent, i.e. vitamin C (ascorbic acid, referred to ...

Embodiment 3

[0061] A method for preparing a water-soluble molecular self-assembled film type metal protective agent, the steps of which are:

[0062] A. Distilled water with a mass ratio of 1.0:10, that is, 2.0kg, and 20kg of organic solvent α-phenylmethyl-ω-[(1,1,3,3-tetramethylbutyl)phenoxy]-poly( Oxygen-1,2-ethylene) (TRITON for short) was mixed in the reaction kettle and stirred for 3 minutes to make a mixed solvent;

[0063] B, add the emulsifying agent of 44.5% of the mixed solvent quality of step A gained, i.e. 9.79kg hydroxyethyl fatty acid propyl fat (HDP), stir 5 minutes, make mixture;

[0064] C. Add 15.5% of the film-forming agent of the mass of the mixture obtained in step B, i.e. 4.93kg 8,14-dihydroxyoctadecyl mercaptan (D-SM), and stir for 6 minutes to further obtain a mixed solution;

[0065] D. Add 1.80% surfactant of the mass of the mixed solution obtained in step C, i.e. sodium dodecyl sulfate (SDS) 0.661kg and 0.3% reducing agent, i.e. vitamin C (ascorbic acid, referr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com