A kind of vacuum freeze-drying process of roses

A vacuum freeze-drying, rose technology, applied in the direction of drying solid materials, drying solid materials without heating, and promoting the preliminary treatment of solid materials drying, etc. Complete, damaged and other problems, to achieve the effect of color stability, improved physical properties, and adequate drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

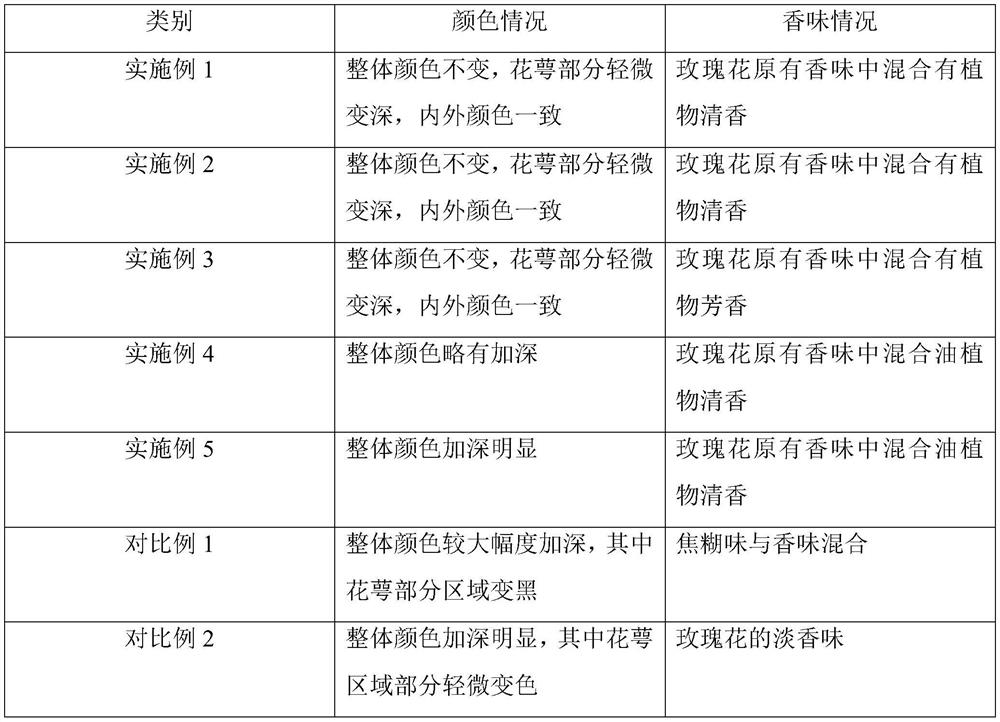

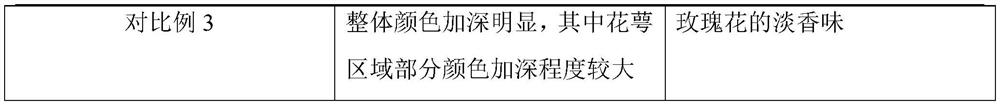

Examples

Embodiment 1

[0026] A process for vacuum freeze-drying roses, comprising the following steps:

[0027] S1 selects fresh roses, requires that the picking period does not exceed 24 hours, and washes the picked roses in clean water to obtain clean roses;

[0028] S2 leaves the cleaned rose flower standstill for 35min in the atomized color-retaining solution, then places it in a vacuum chamber, and controls the air pressure in the vacuum chamber to be 10kPa; the weight component of the color-retaining solution includes 43 parts of ultrapure water , 17 parts of tartaric acid, 7 parts of jojoba oil and 7 parts of almond oil; using jojoba oil as a dispersant, carrying tartaric acid and almond oil into the petal cells of roses, while jojoba oil and almond oil The good antioxidant properties of oil are combined with the antioxidant properties of tartaric acid, which can reduce the solidification temperature of roses to a certain extent, so that roses can maintain the stability of the cells in the p...

Embodiment 2

[0033] The weight components of the color retention solution were changed to 40 parts of ultrapure water, 10 parts of tartaric acid, 5 parts of jojoba oil and 5 parts of almond oil, and other formulas and steps were the same as in Example 1.

Embodiment 3

[0035] The weight components of the color retention solution were changed to 50 parts of ultrapure water, 20 parts of tartaric acid, 10 parts of jojoba oil and 10 parts of almond oil, and other formulas and steps were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com