Patents

Literature

35results about How to "Little discoloration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-resistant high-temperature-resistant single-component waterborne polyurethane adhesive and preparation method thereof

InactiveCN108342181AHigh strengthImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

The invention discloses a water-resistant high-temperature-resistant single-component waterborne polyurethane adhesive and a preparation method thereof and relates to the technical field of polyurethane adhesives. The adhesive comprises, by weight, 30-40 parts of polytetrahydrofuran glycol, 15-22 parts of polycarbonate diol, 3-7 parts of poly-2,6-polyethylene naphthalate polyester glycol, 17-25 parts of diisocyanate, 2-5 parts of chain extender, 0.5-2 parts of silane coupling agent modified silicon dioxide nanoparticles, 0.1-0.6 part of dibutyltin dilaurate, 4-8 parts of acetone, 1-3 parts oftriethylamine, 0.05-0.1 part of sodium hydroxide and an appropriate amount of water. Polytetrahydrofuran and polycarbonate diol are adopted as oligomer polyhydric alcohols in raw materials for preparing polyurethane, and added poly-2,6-polyethylene naphthalate polyester glycol is introduced to a soft-segment part of polyurethane; by adding silane coupling agent modified silicon dioxide nanoparticles, the mechanical properties and heat resistance of the adhesive can be improved; the prepared adhesive is high in adhesive force and excellent in water resistance and high temperature resistance, and the application range of the adhesive is enlarged.

Owner:佛山市三水日邦化工有限公司

Durable flame-retardant, water-repellent, waterproof and moisture permeable finishing method of polyester fabric

ActiveCN106049049AEffective Flame RetardancyDoes not affect flame retardancyFireproof paintsHeat resistant fibresPolyesterAdhesive

The invention relates to a durable flame-retardant, water-repellent, waterproof and moisture permeable finishing method of a polyester fabric. A flame-retardant and water-repellent finishing agent is prepared from 20-30 parts of cyclic phosphate flame retardants, 60-70 parts of water, 1-1.5 parts of isocyanate cross-linking agents, 3-5 parts of fluorocarbon copolymer waterproof agents and 2-5 parts of NaOH with 10% mass concentration. A bottom coating adhesive is prepared from 100 parts of polyether polyurethane polymer under-coating adhesives, 5-10 parts of methylbenzene, 5-10 parts of butanone, 2 parts of isocyanate cross-linking agents, 1 part of accelerant and 25-35 parts of organic phosphorus-nitrogen flame retardants. A surface coating adhesive is prepared from 100 parts of polyether polyurethane polymer top-coating adhesives and 35-45 parts of methylbenzene. The fabric is padded, calendered, under-coated and top-coated with water repellents to achieve finishing by the flame-retardant and water-repellent finishing agent, the bottom coating adhesive and the surface coating adhesive.

Owner:DANDONG UNIK TEXTILE

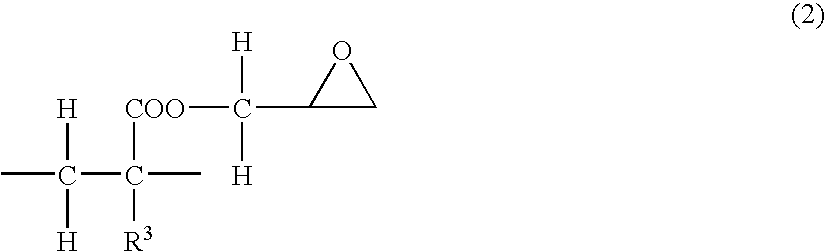

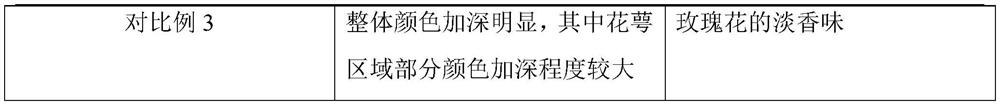

Epoxy resin composition

ActiveUS7112636B2Good light transmissionLittle discolorationOther chemical processesLuminescent compositionsCompound aEpoxy

An epoxy resin composition comprising an epoxy resin, a hardening agent and a hardening accelerator as an indispensable ingredients is provided wherein the hardened resin has a high translucency and has little discoloration under high temperature and high humidity and is excellent at heat resistance and light fastness by compounding a phosphonium compound represented by the following formula (I) as a hardening accelerator.

Owner:NICHIA CORP

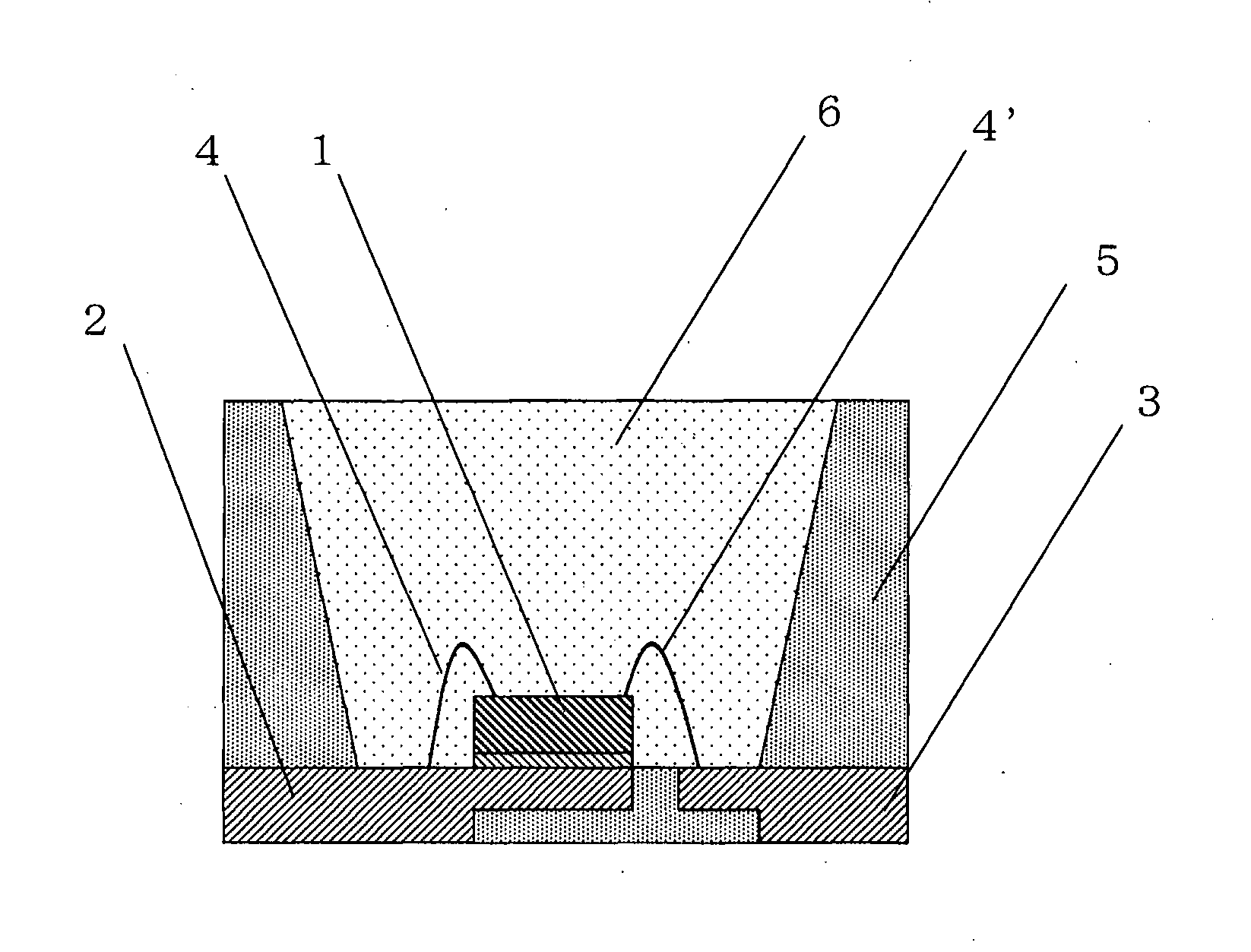

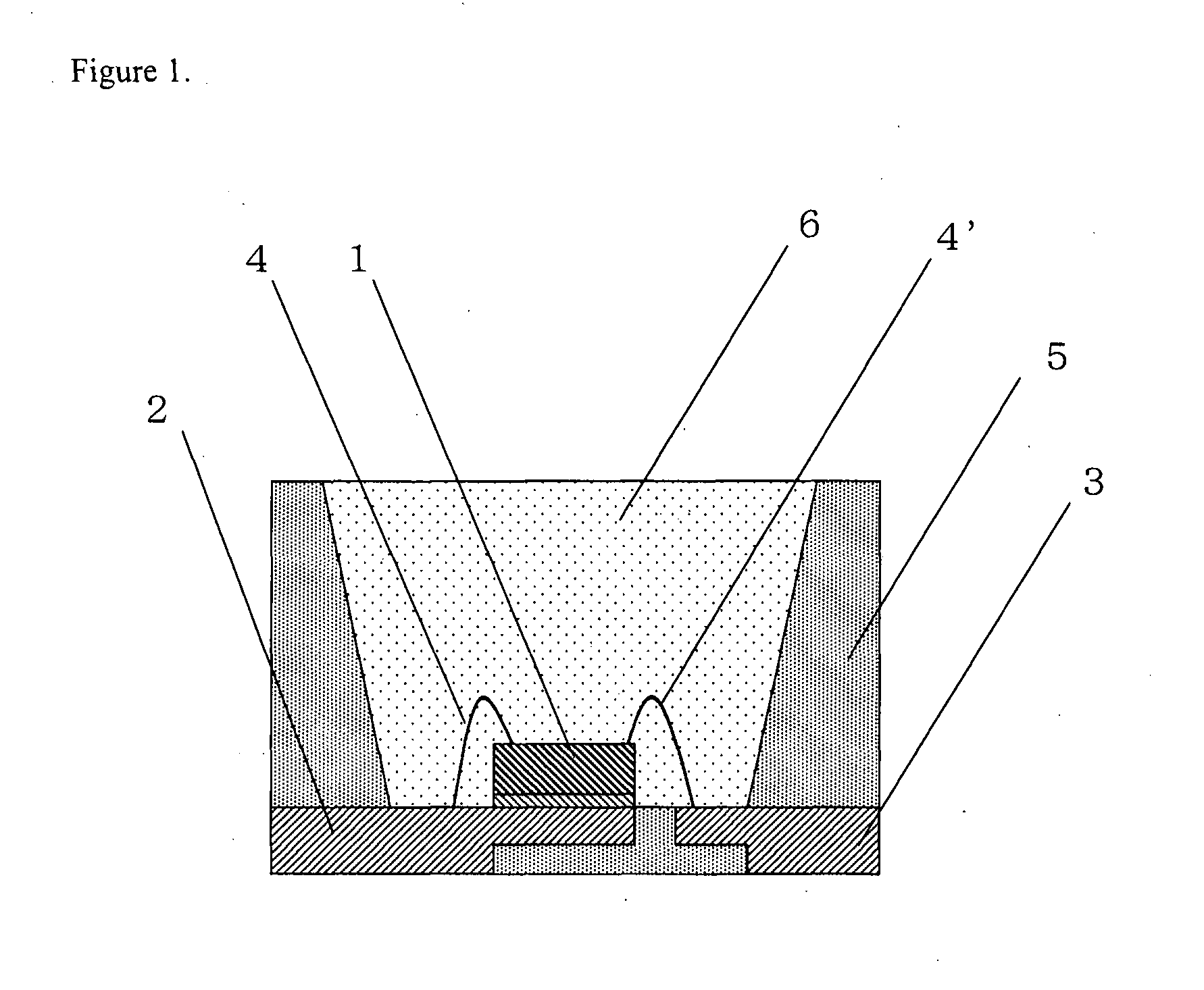

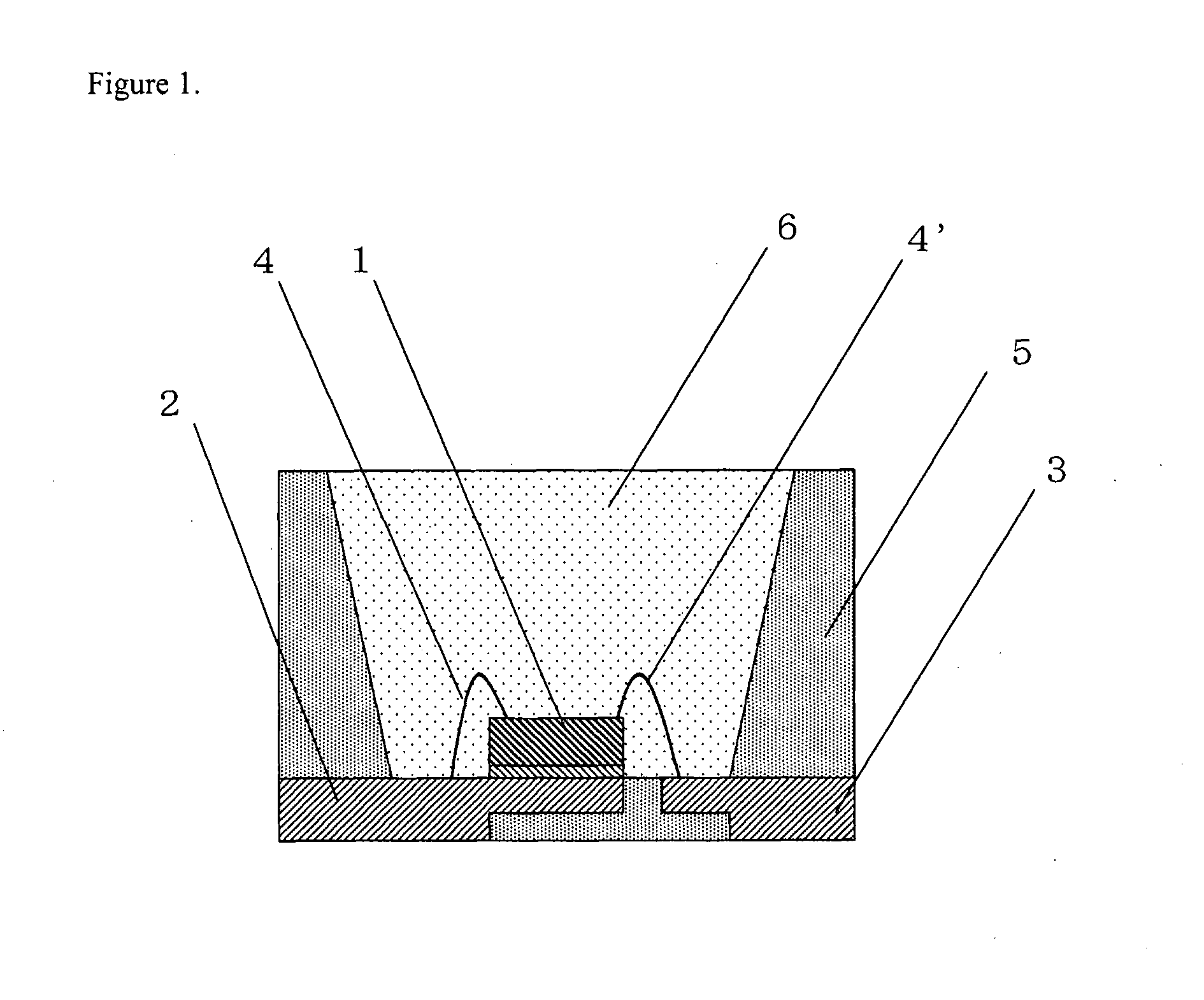

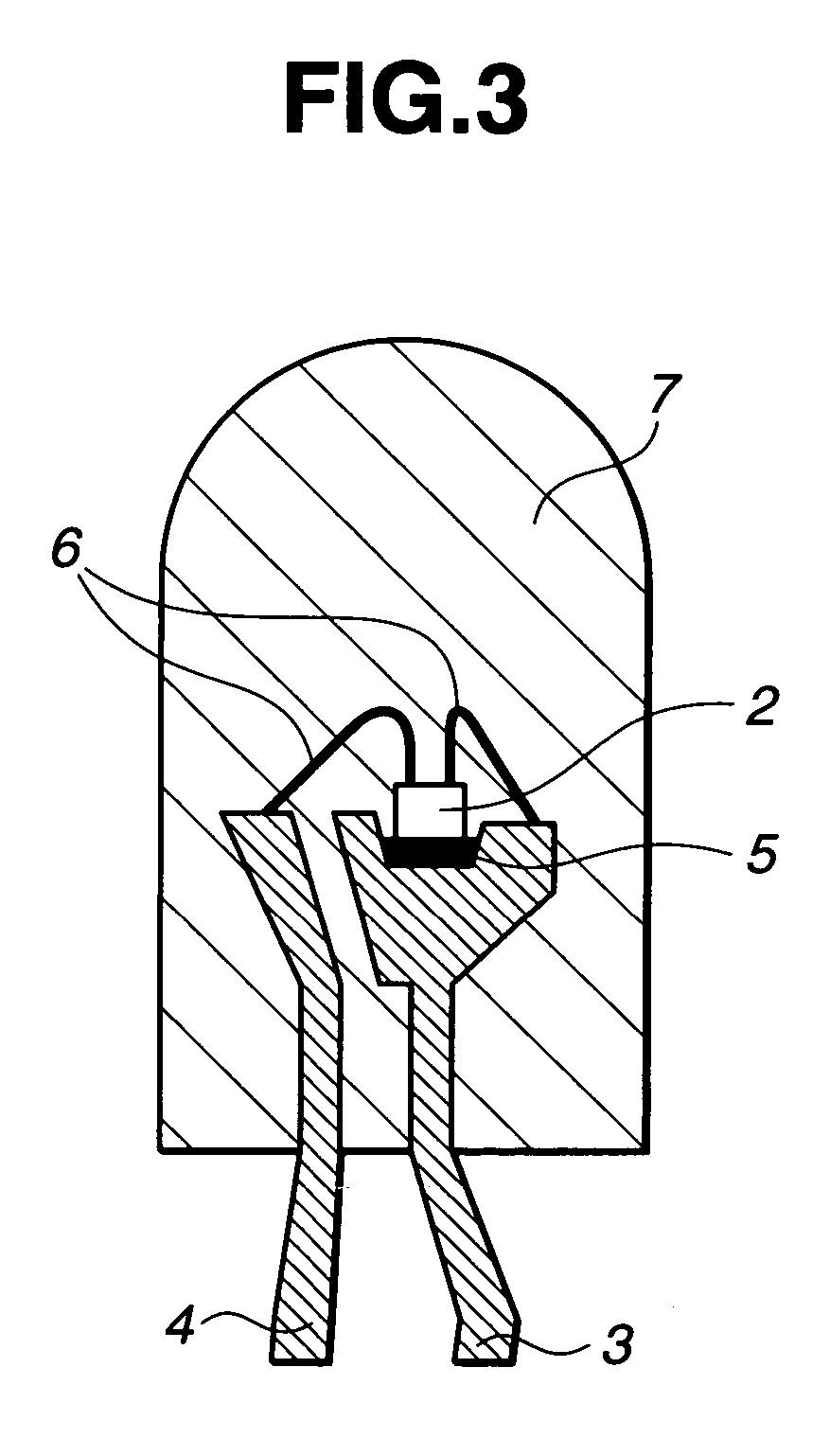

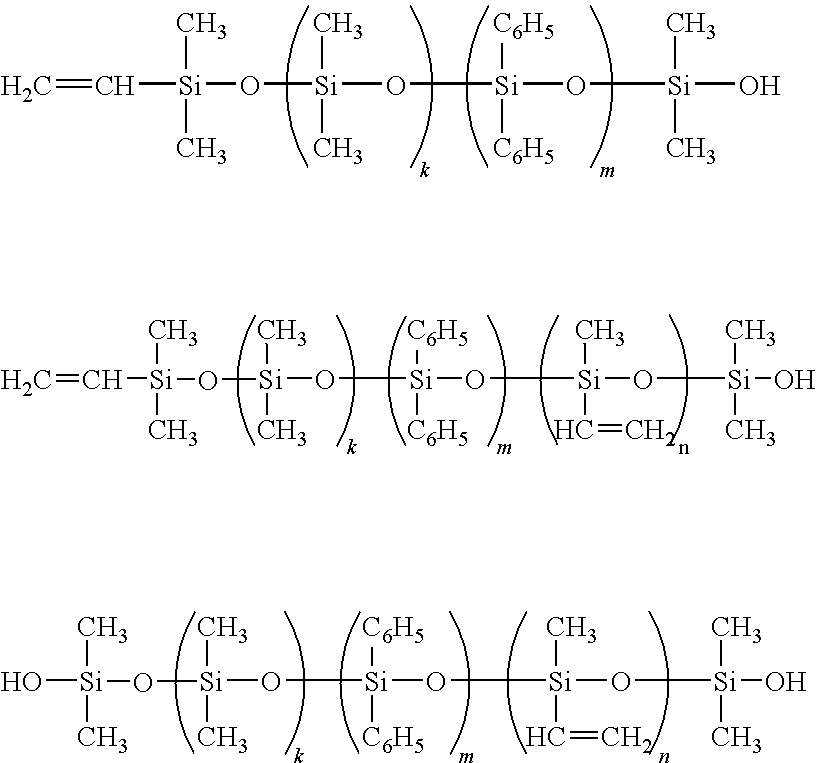

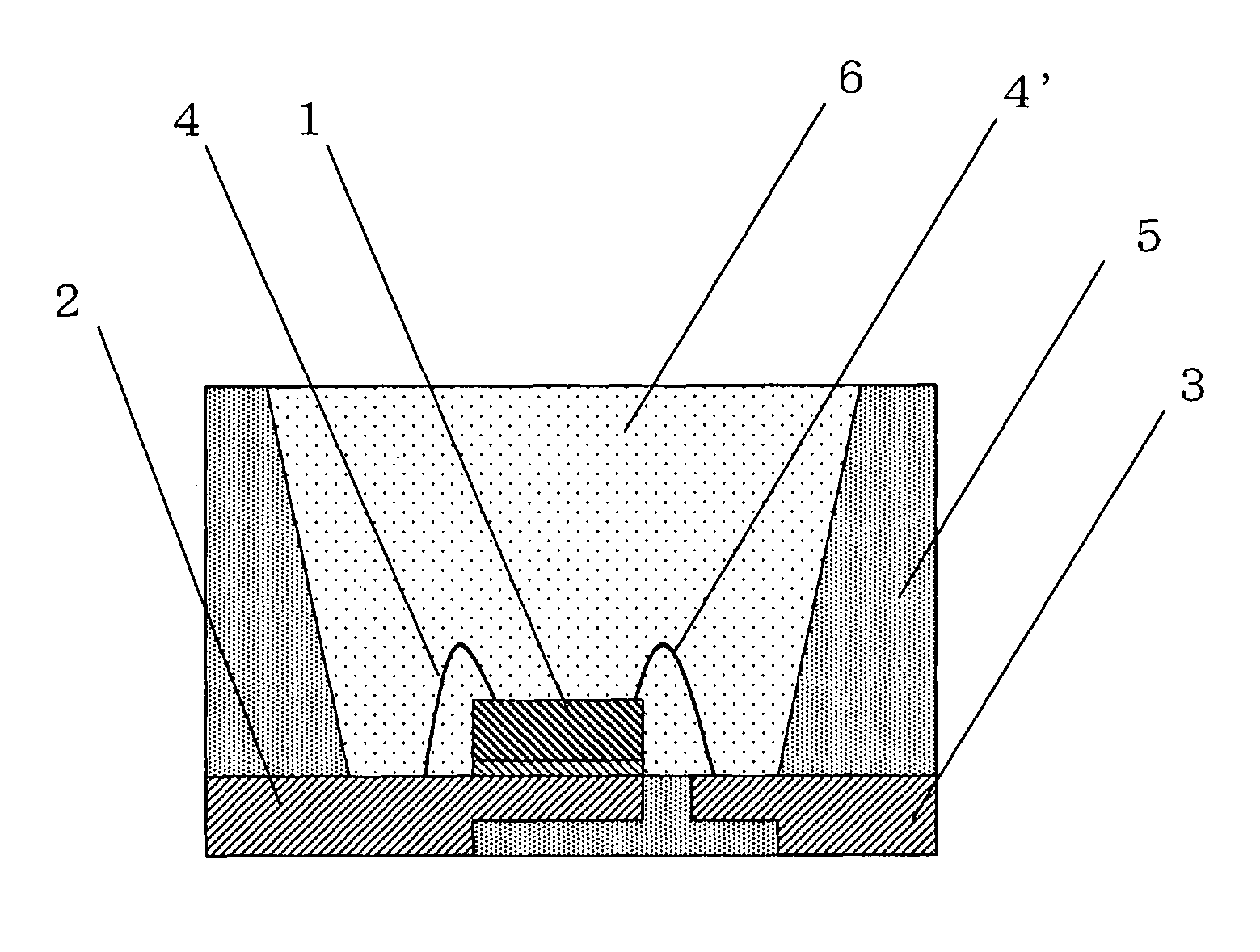

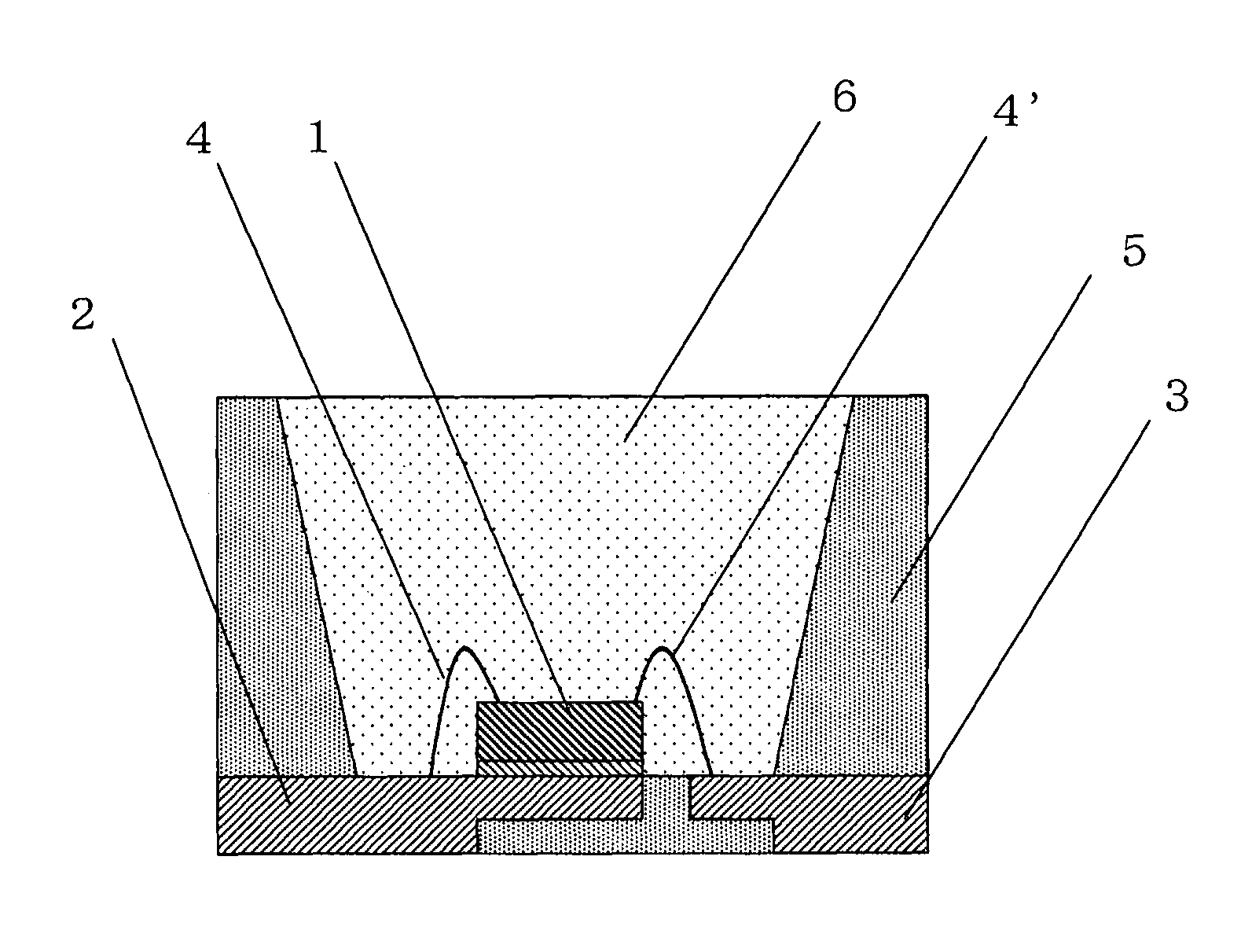

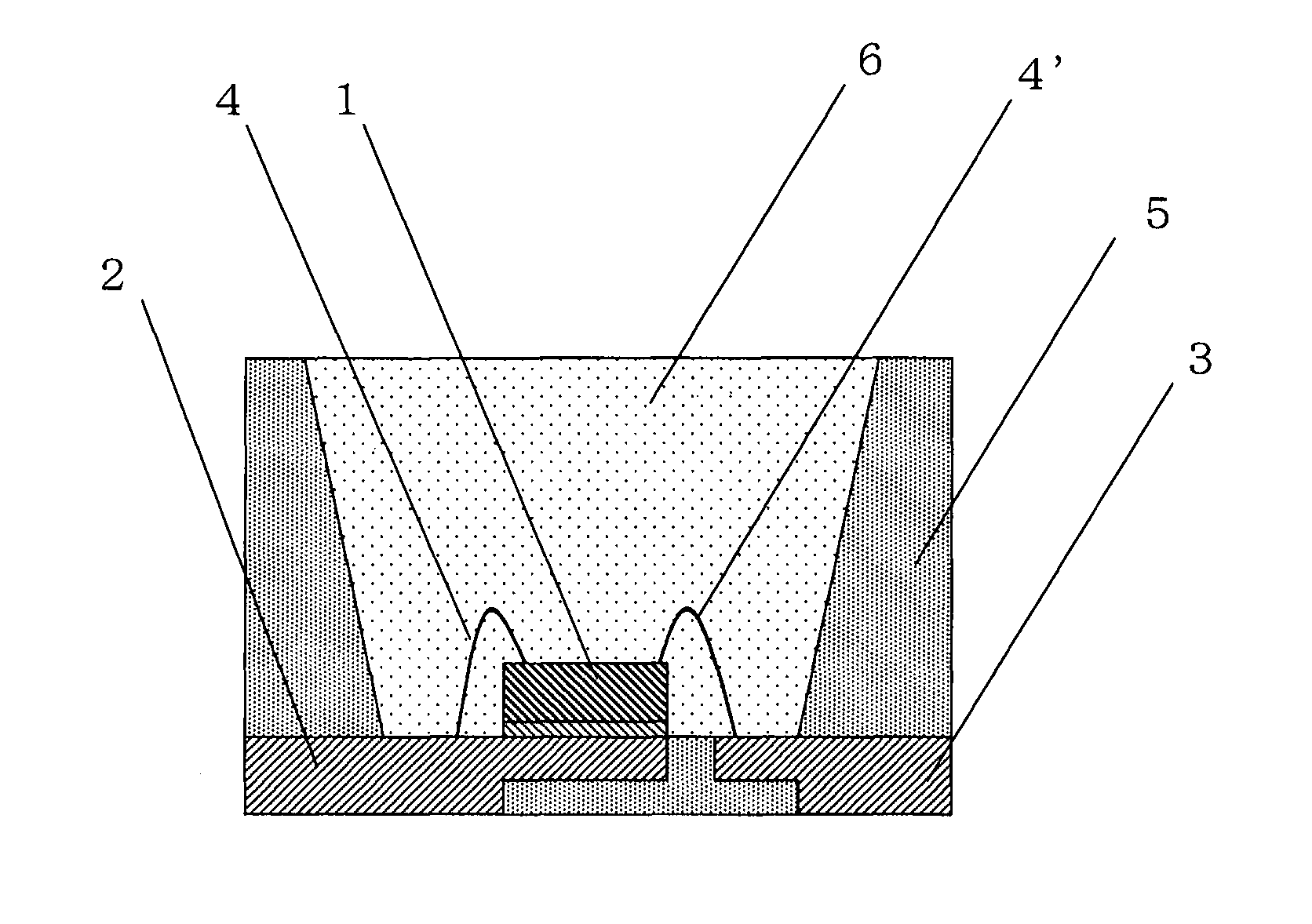

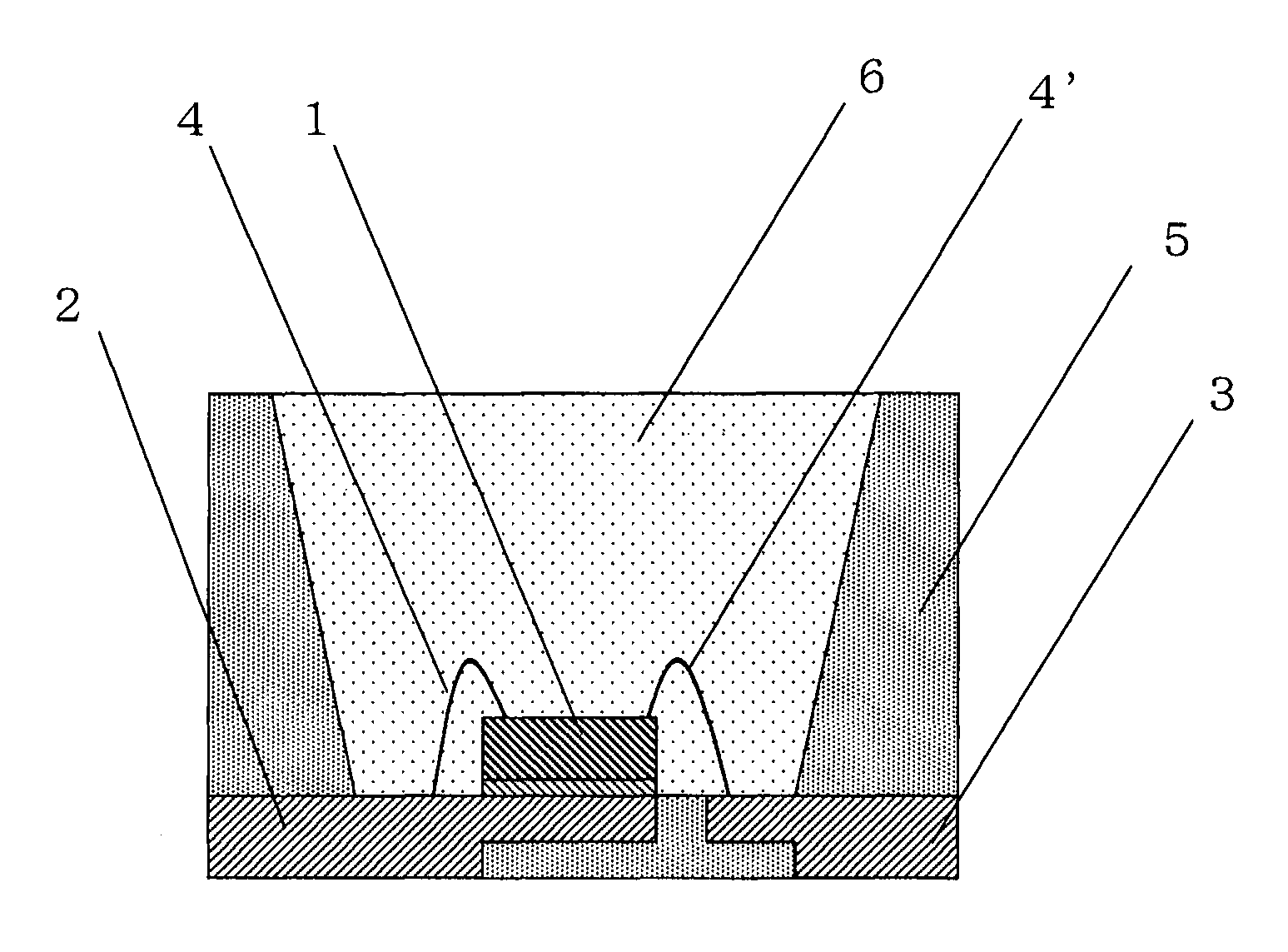

Curable Silicone Composition, Cured Product Thereof, And Optical Semiconductor Device

InactiveUS20150001569A1Little discoloration and lowering of mechanical strengthImprove reflectivitySolid-state devicesSemiconductor devicesPolymer scienceHydrosilylation

A curable silicone composition comprises: (A) an organopolysiloxane represented by an average unit formula; (B) an organopolysiloxane having 10 or less silicon atoms, wherein 30 to 60 mole % of all silicon atom-bonded organic groups are alkenyl groups having from 2 to 6 carbons; (C) an organopolysiloxane represented by a general formula; (D) an organopolysiloxane having at least 2 silicon atom-bonded hydrogen atoms in a molecule, wherein the content of phenyl groups in all silicon atom-bonded organic groups in this component is 20 to 70 mole %; (E) an organopolysiloxane represented by an average unit formula; (F) a hydrosilylation reaction catalyst; (G) a white pigment; and (H) an inorganic filler other than a white pigment, has excellent formability for forming a cured product that has little discoloration and lowering of mechanical strength by heat and light, has high light reflectance, has excellent dimensional stability, and is capable of good attachment by a sealing agent used for an optical semiconductor device.

Owner:DOW CORNING TORAY CO LTD

High-temperature no-dropping-point lubricating grease and production technique thereof

InactiveCN102051256ALong fatliquoring cycleWide adaptabilityLubricant compositionSulfonateSodium Bentonite

The invention relates to a high-temperature no-dropping-point lubricating grease and a production technique thereof. The high-temperature no-dropping-point lubricating grease is prepared from the following components in parts by weight: 13.7-84.4 parts of base oil, 5-15 parts of bentonite thickener, 5-50 parts of composite calcium sulfonate lubricating grease, 5-20 parts of tackifier, 0.5-1 part of antioxidant and 0.1-0.3 part of metal deactivator. The preparation method of the composite calcium sulfonate lubricating grease comprises the following steps: converting superhigh-base-number calcium sulfonate with a conversion agent at 60-100 DEG C for 20-60 minutes until the superhigh-base-number calcium sulfonate becomes obviously thickened, and heating to 140-180 DEG C to remove water. The high-temperature no-dropping-point lubricating grease has the advantages of long grease addition period and wide adaptability, and can be used in high-temperature positions; and at high temperature, the high-temperature no-dropping-point lubricating grease also has the advantages of no coking, light discolorment, less oil bleeding, low loss and longer service life.

Owner:辽宁海华科技股份有限公司

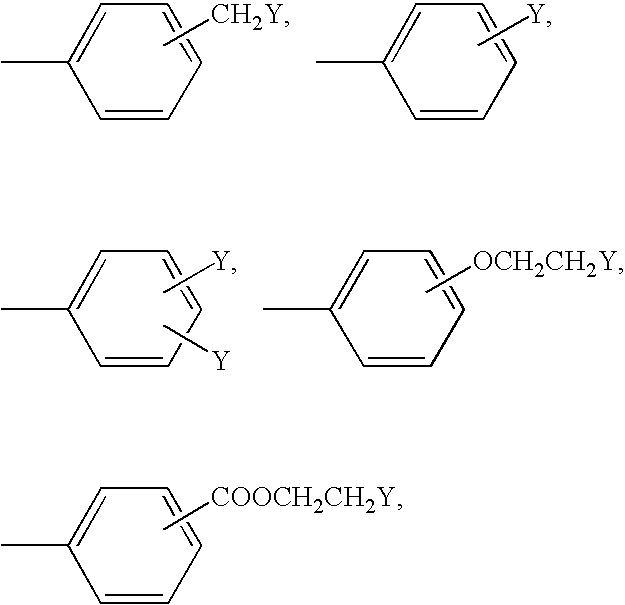

Dental Polymerizable Composition

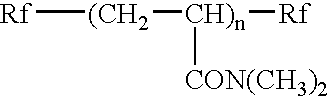

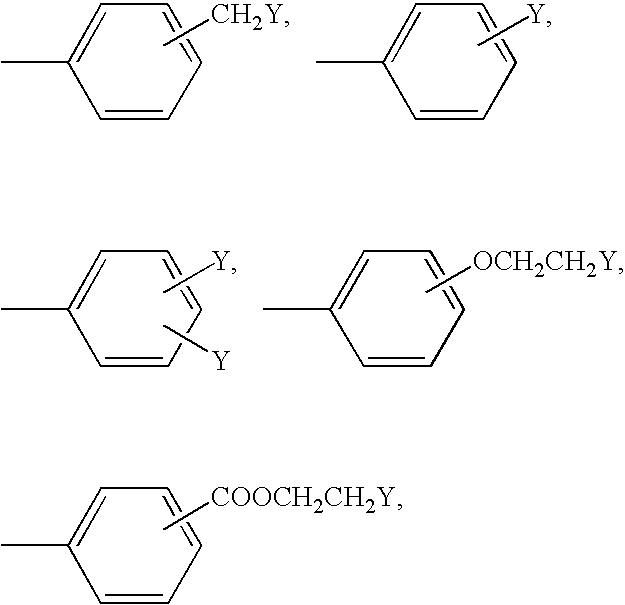

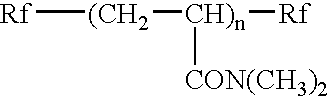

ActiveUS20080039592A1Improve antifouling performanceMaintains glazeImpression capsTeeth fillingEnd-groupFilling materials

A dental polymerizable composition comprising (a) a fluorine compound comprising a chain polymer having a main chain comprising a monomer unit having a hydrophilic group, and terminal groups comprising a fluoroalkyl group at each of both ends of the main chain; (b) a polymerizable monomer; and (c) a polymerization initiator. The dental polymerizable composition can be suitably used, for example, for dental composite resins, such as dental composite filler materials, crowning materials, and bonding materials; dental adhesive agents, such as teeth-straightening adhesive agents, cavity-coating adhesive agents, and tooth fissure sealing materials; denture base materials, denture base mucosal adjusting materials, fissure sealants, coating agents applied to tooth surface or dental prosthetic, surface glazes, and the like, and especially for various coating applications, for example, a fissure sealant, a coating agent to tooth surface or dental prosthetic, surface stains or a surface glaze, a hypersensitive inhibitor, a dental manicure, or the like.

Owner:KURARAY NORITAKE DENTAL

Curable Silicone Composition, Cured Product Thereof, And Optical Semiconductor Device

InactiveUS20140367723A1Good molding effectLittle discolorationPlastic/resin/waxes insulatorsSolid-state devicesPolymer scienceHydrosilylation

A curable silicone composition comprises: (A) an organopolysiloxane represented by an average unit formula; (B) an organopolysiloxane having 10 or less silicon atoms, wherein 30 to 60 mole % of all silicon atom-bonded organic groups are alkenyl groups having from 2 to 6 carbons; (C) an organopolysiloxane represented by a general formula; (D) an organopolysiloxane having at least 2 silicon atom-bonded hydrogen atoms in a molecule, wherein the content of phenyl groups in all silicon atom-bonded organic groups in this component is at least 20 mole %; (E) an organopolysiloxane having at least 2 silicon atom-bonded hydrogen atoms in a molecule, wherein the content of phenyl groups in all silicon atom-bonded organic groups in this component is less than 20 mole %; (F) a hydrosilylation reaction catalyst; (G) a white pigment; and (H) an inorganic filler other than a white pigment, has excellent formability for forming a cured product that has little discoloration and lowering of mechanical strength by heat and light, has high light reflectance, has excellent dimensional stability, and is capable of good attachment by a sealing agent used for an optical semiconductor device.

Owner:DOW CORNING TORAY CO LTD

Fuel-barrier thermoplastic resin compositions and articles

InactiveUS20060270799A1Prevent solidificationRaise the reaction temperatureBottlesSynthetic resin layered productsThermoplasticPolyolefin

A thermoplastic resin article which includes a layer made of a thermoplastic resin composition containing 50 to 97% by weight of a polyolefin A, 2 to 45% by weight of a barrier resin B, and 1 to 45% by weight of a modified polyolefin Ca and / or a styrene copolymer Cb. The ratio of the melt viscosities of the polyolefin A and the barrier resin B satisfies the formula: 0.7<MVB / MVA<2.8 wherein MVA is a melt viscosity (Pa·s) of the polyolefin A and MVB is a melt viscosity (Pa·s) of the barrier resin B, each measured under a shear rate of 100 s−1 at a temperature from MP+2° C. to MP+10° C. wherein MP is the melting point of the barrier resin B. The thermoplastic resin article exhibits good fuel barrier properties and impact resistance.

Owner:MITSUBISHI GAS CHEM CO INC

Heat-curable resin composition and use thereof

ActiveUS7098258B2Excellent curabilityLittle discolorationOrganic chemistryPhotosensitive materialsChemistryWhite lead

The heat-curable resin composition of the present invention comprises an epoxy-containing resin and a curing agent, wherein the curing agent is cyclohexanetricarboxylic acid and / or an anhydride thereof. The heat-curable resin composition exhibits an excellent curability without using an curing accelerator and provides a colorless transparent cured product which is little discolored under high-temperature conditions and irradiation conditions of high-energy light. The heat-curable resin composition is suitable for producing coating compositions, adhesives, shaped articles, protective films for color filters and sealing materials for photosemiconductors such as blue LED and white LED.

Owner:MITSUBISHI GAS CHEM CO INC

Dental polymerizable composition

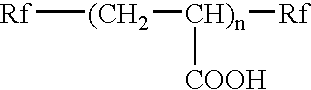

ActiveUS7683103B2Improve antifouling performanceLittle discolorationImpression capsTeeth fillingEnd-groupFilling materials

A dental polymerizable composition comprising (a) a fluorine compound comprising a chain polymer having a main chain comprising a monomer unit having a hydrophilic group, and terminal groups comprising a fluoroalkyl group at each of both ends of the main chain; (b) a polymerizable monomer; and (c) a polymerization initiator. The dental polymerizable composition can be suitably used, for example, for dental composite resins, such as dental composite filler materials, crowning materials, and bonding materials; dental adhesive agents, such as teeth-straightening adhesive agents, cavity-coating adhesive agents, and tooth fissure sealing materials; denture base materials, denture base mucosal adjusting materials, fissure sealants, coating agents applied to tooth surface or dental prosthetic, surface glazes, and the like, and especially for various coating applications, for example, a fissure sealant, a coating agent to tooth surface or dental prosthetic, surface stains or a surface glaze, a hypersensitive inhibitor, a dental manicure, or the like.

Owner:KURARAY NORITAKE DENTAL

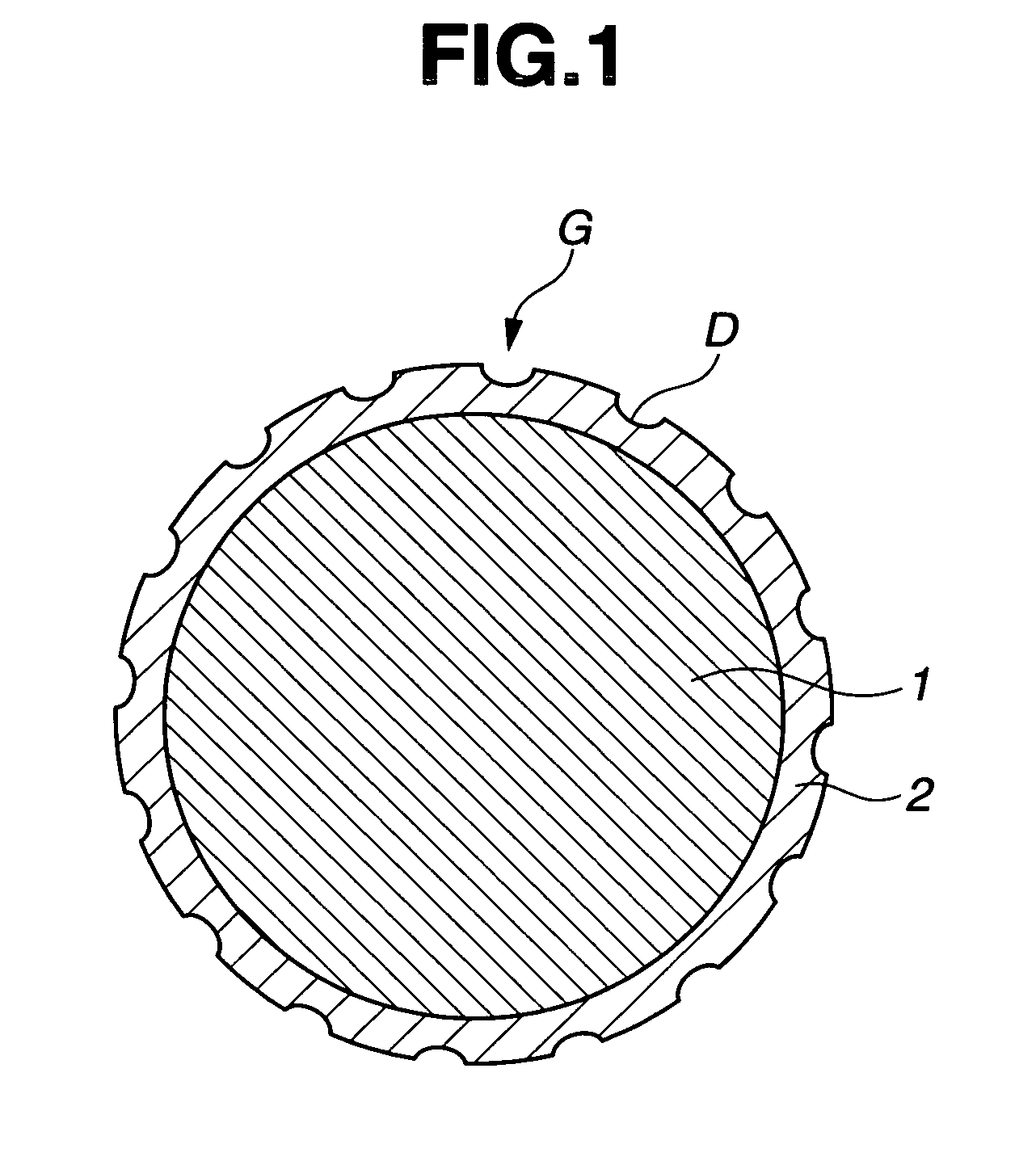

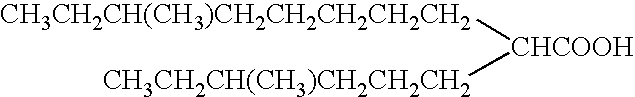

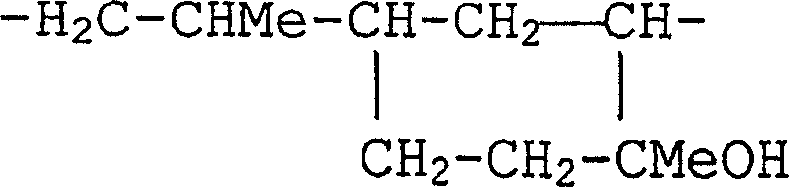

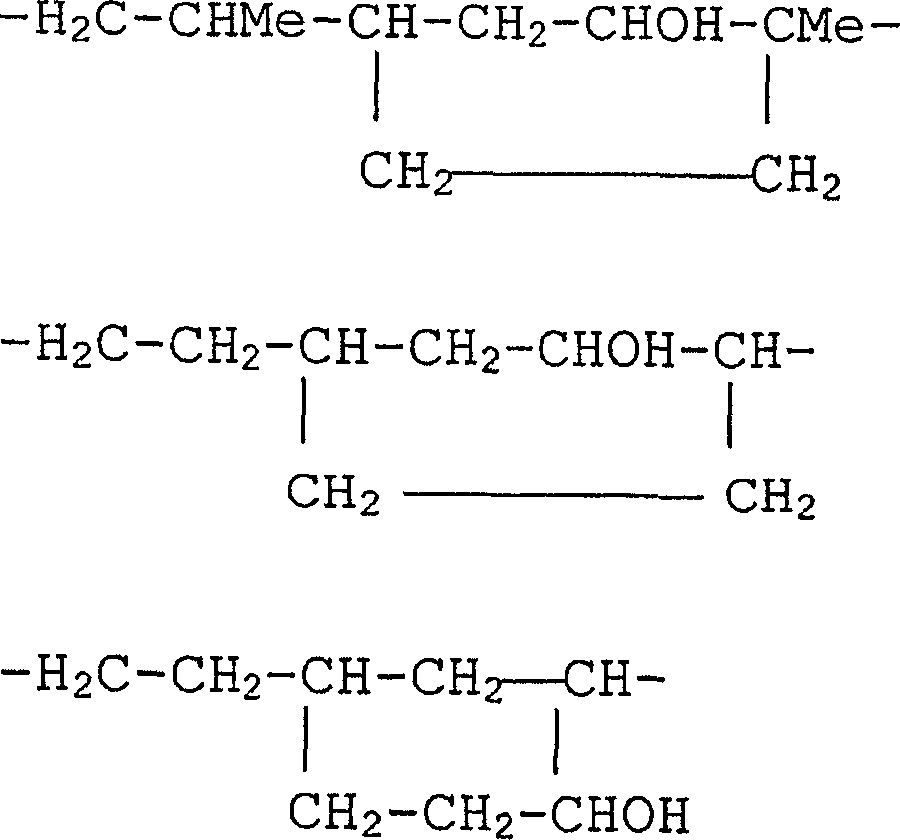

Golf ball

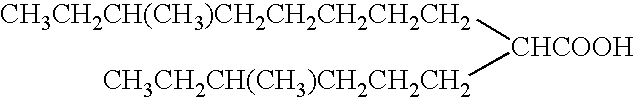

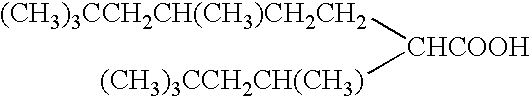

InactiveUS7838584B2Improve wear resistanceImprove impactFibre treatmentSynthetic resin layered productsBranched chain fatty acidsEngineering

The invention provides a golf ball having a core and a cover of one or more layer, wherein at least one layer of the cover is made of a material obtained by molding a mixture composed of (a) 100 parts by weight of a base resin and (b) 1 to 40 parts by weight of a saturated branched-chain fatty acid or a derivative thereof. The golf ball has a soft, pleasant feel on impact and excellent scuff resistance while retaining a good flight performance. Moreover, it exhibits a highly white appearance that undergoes little discoloration.

Owner:BRIDGESTONE SPORTS

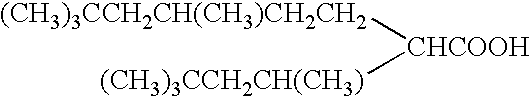

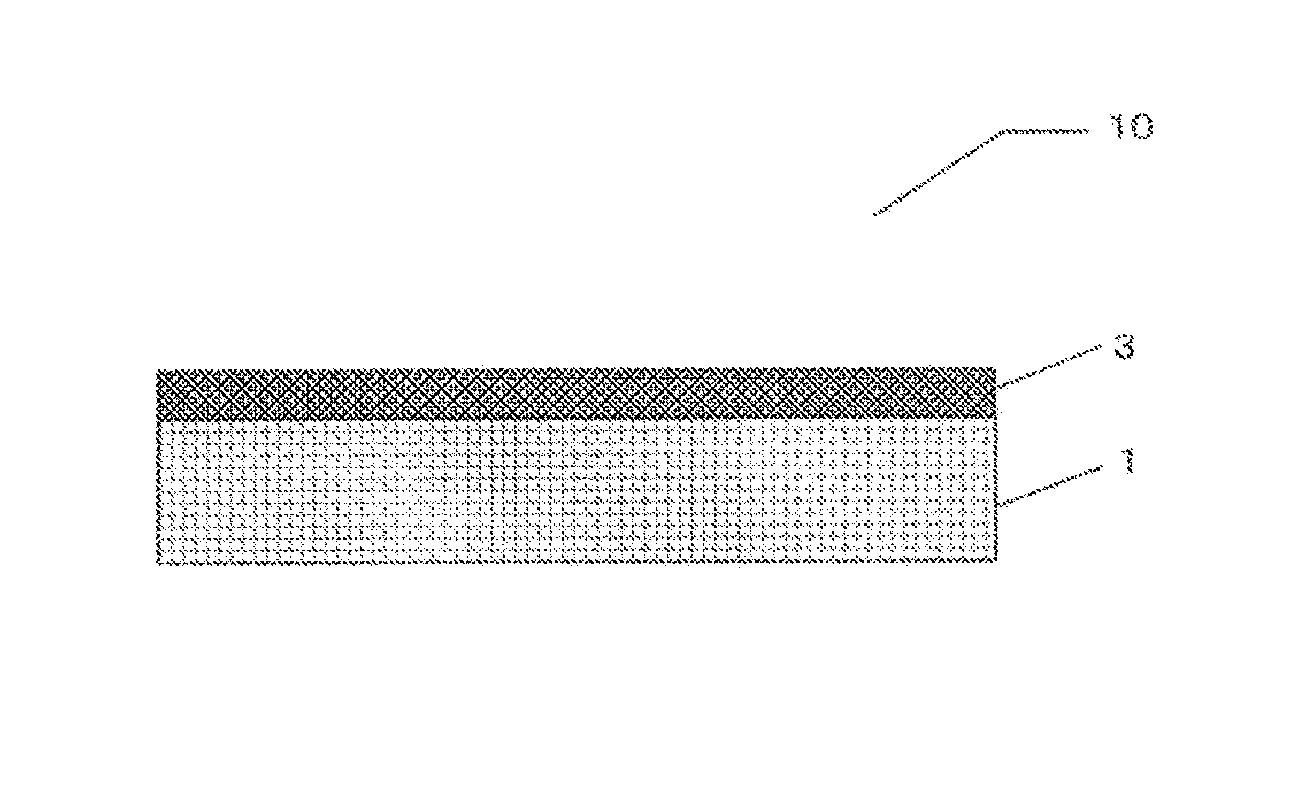

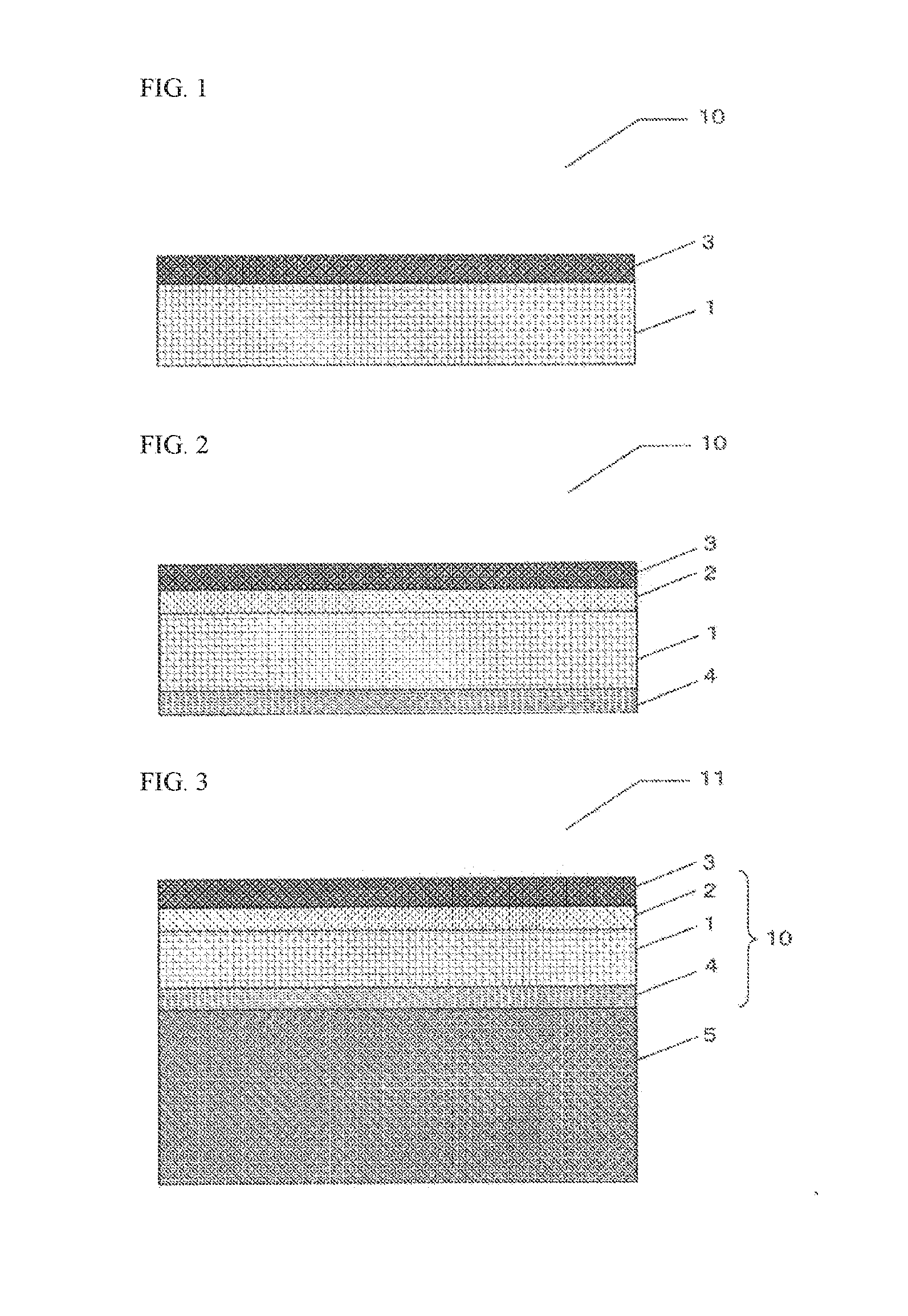

Laminating film for use in organic glass

InactiveUS20160185925A1High transparencyLittle discolorationProtective equipmentSynthetic resin layered productsMeth-Weather resistance

The purpose of the present invention is to provide: a laminating film which is to be used in an organic glass, which suffers from little discoloration of a resin film even after electron beam irradiation and thus exhibits excellent transparency, and which exhibits excellent weather resistance and scratch resistance and excellent three-dimensional molding properties; and an organic glass using the same. In a laminating film which is to be used in an organic glass and which comprises both a resin film that contains a triazine ultraviolet absorber and a surface protection layer, the surface protection layer is formed of a cured product of an electron-beam-curable resin composition that comprises a polycarbonate (meth)acrylate and a polyfunctional (meth)acrylate at a mass ratio of 98:2 to 50:50. An organic glass is manufactured using the laminating film.

Owner:DAI NIPPON PRINTING CO LTD

Fuel barrier single-layered structure and multi-layered shaped article

ActiveUS20070049692A1Prevent solidificationRaise the reaction temperatureSynthetic resin layered productsThin material handlingPolyolefinDicarboxylic acid

Owner:MITSUBISHI GAS CHEM CO INC

Golf ball

InactiveUS20080039563A1Improve wear resistanceImprove impactFibre treatmentSynthetic resin layered productsBranched chain fatty acidsEngineering

The invention provides a golf ball having a core and a cover of one or more layer, wherein at least one layer of the cover is made of a material obtained by molding a mixture composed of (a) 100 parts by weight of a base resin and (b) 1 to 40 parts by weight of a saturated branched-chain fatty acid or a derivative thereof. The golf ball has a soft, pleasant feel on impact and excellent scuff resistance while retaining a good flight performance. Moreover, it exhibits a highly white appearance that undergoes little discoloration.

Owner:BRIDGESTONE SPORTS

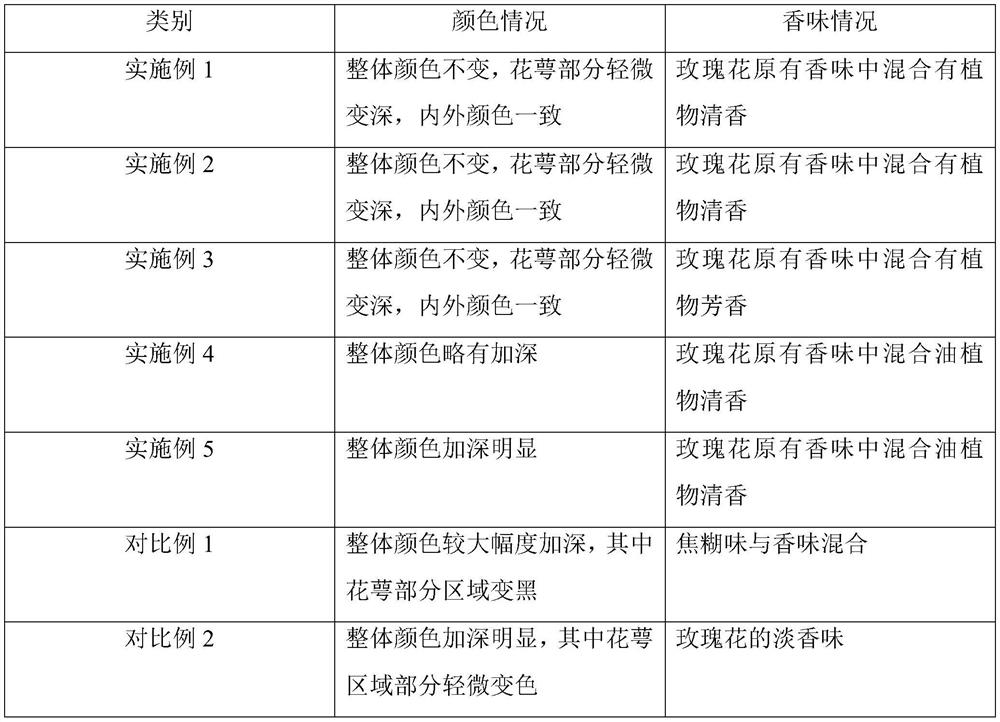

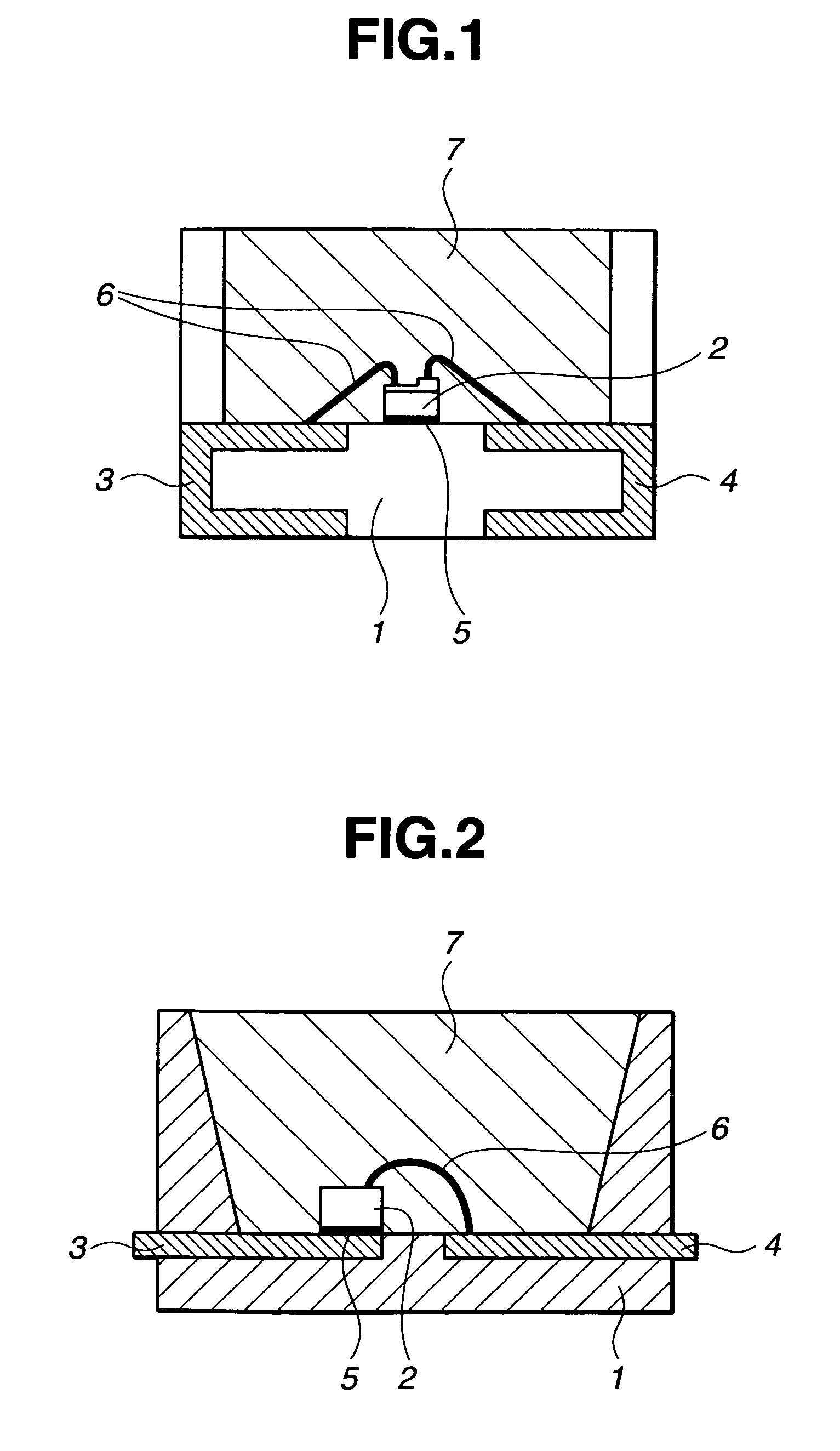

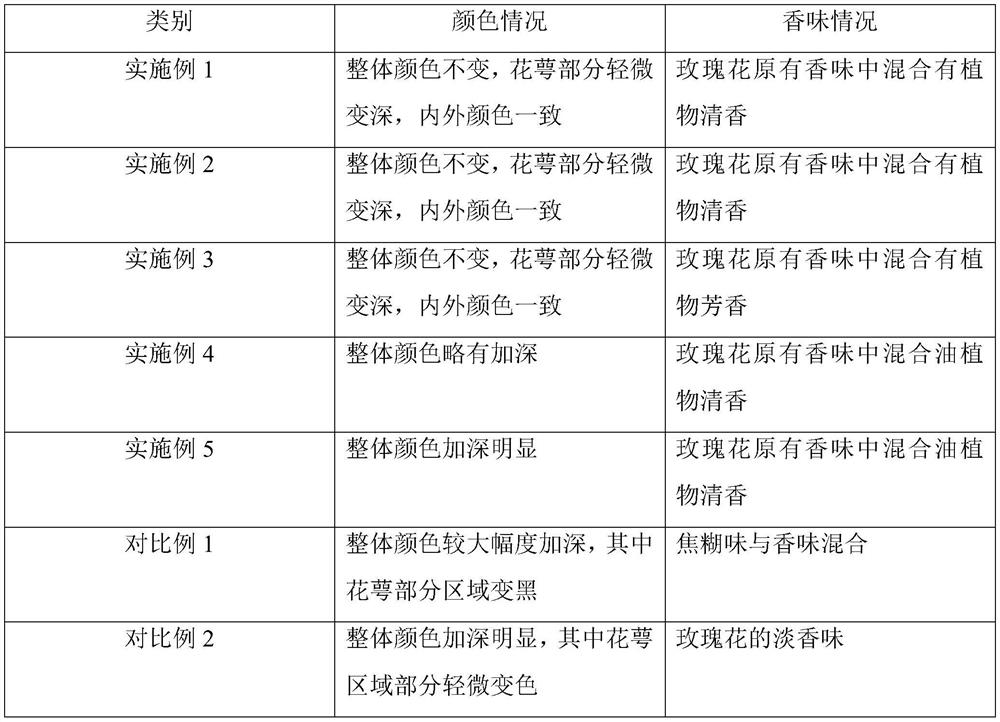

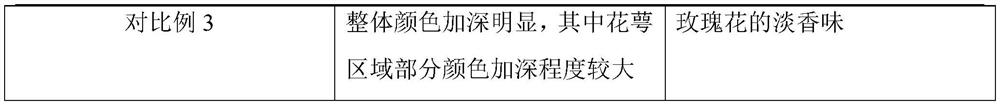

Process for vacuum freeze drying of roses

ActiveCN111721073AImprove physical propertiesRealize the collectionDrying solid materials without heatPreliminary solid treatment for dryingFreeze-dryingPetal

The invention discloses a process for vacuum freeze drying of roses. The process comprises the following steps of S1, picking and treating the roses; S2, treating the roses with a color-retaining solution; S3, freeze-drying the roses; S4, drying the roses by gradient heating; and S5, performing low-temperature condensation and collection on rose hydrolat. The process for vacuum freeze drying of the roses has the beneficial effects that the color-retaining solution is utilized and atomized, so that collection and utilization of the roses are realized; the stability of petal cells is kept by utilizing simmondsia chinensi oil, tartaric acid and apricot kernel oil, and meanwhile, the oxidation resistance of the simmondsia chinensi oil, tartaric acid and apricot kernel oil is combined and superposed to stabilize the overall color of petals, so that sufficient drying is realized; collection and utilization are realized by utilizing three-stage heating; collection and utilization are achievedby limiting low-temperature condensation and collection conditions; sufficient drying is realized by atomizing the color-retaining solution; and sufficient drying is achieved by standing for 35 min.

Owner:银谷芳香科技有限公司

Epoxy/silicone hybrid resin composition and optical semiconductor device

InactiveUS7592399B2Eliminate needLow elastic modulusSemiconductor/solid-state device detailsSolid-state devicesEpoxySilylene

An epoxy / silicone hybrid resin composition is provided comprising (A) an organosilicon compound having at least one silicon-bonded hydroxyl group, (B) a modified epoxy resin which is free of a phenylene ether skeleton and has reactive hydroxyl groups wherein some or all of the hydrogen atoms of the reactive hydroxyl groups are substituted by monovalent hydrocarbon groups or silyl groups, and (C) an aluminum base curing catalyst. The compatibility between silicone and epoxy resins is improved without a need for compatibilizing agent.

Owner:SHIN ETSU CHEM IND CO LTD

Photocatalytic titanium oxide sol, and coating composition and member using the same

ActiveUS7879757B2Little discolorationLittle gelationLayered productsGold compoundsCatalytic oxidationAmmonium hydroxide

A photocatalytic titanium oxide sol presents antibacterial properties in a dark place, and, in particular, relates to a photocatalytic titanium oxide sol which is stable and causes no discoloration by light even though containing silver, and relates to a coating composition and a member using the same. The photocatalytic titanium oxide sol includes silver, copper and a quaternary ammonium hydroxide, may be dispersed in a binder, and may be coated on the surface of a substrate.

Owner:TAKI CHEM CO LTD +1

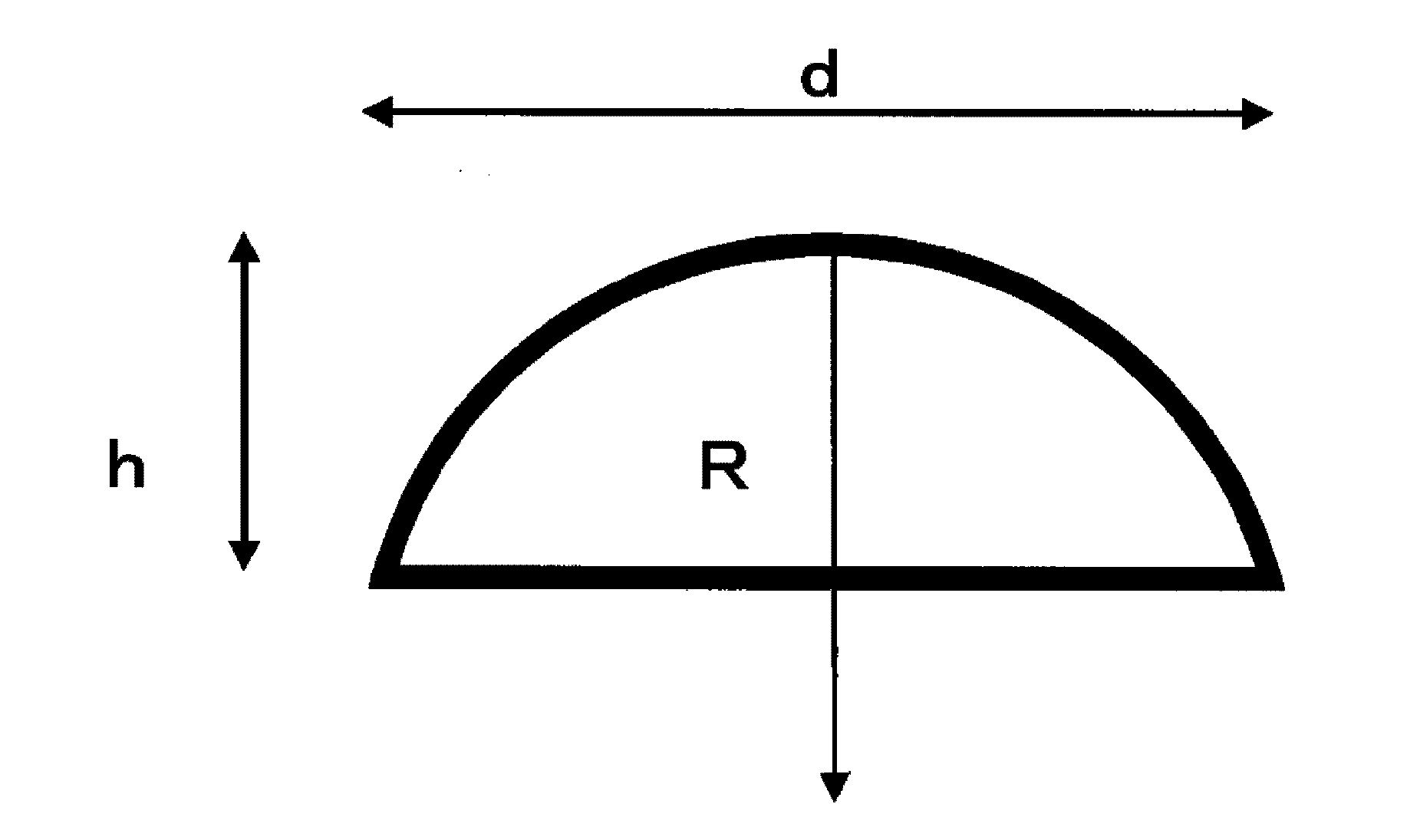

Soluble glassy antimicrobial agent and water-treatment agent

ActiveCN102834001AImprove antibacterial propertiesSmall attenuationBiocideDead animal preservationSolubilityNuclear chemistry

Disclosed is a soluble glassy antimicrobial agent that, when used for water treatment, exhibits a sufficient antimicrobial effect with minimal degradation and discoloration. Also disclosed is a granular water-treatment agent that has excellent filling and processing performance. The disclosed soluble glassy antimicrobial agent contains, in terms of oxide mass, 0-5% SiO2, 5-10% K2O, 0.1-5% Ag2O, 60-75% B2O3, 10-20% Al2O3, and between 0 and 10% of at least one oxide selected from among MgO, BaO, and ZnO. Said soluble glassy antimicrobial agent exhibits high antimicrobial performance with minimal degradation and discoloration. The disclosed water-treatment agent consists of the disclosed soluble glassy antimicrobial agent shaped into grains that bulge on at least one side. The result has excellent filling performance and water permeability and is highly useful as a water-treatment agent.

Owner:TOAGOSEI CO LTD

Curable silicone composition, cured product thereof, and optical semiconductor device

InactiveUS9048406B2Little discoloration and lowering of mechanical strengthImprove reflectivitySolid-state devicesSemiconductor devicesPolymer scienceHydrosilylation

A curable silicone composition comprises: (A) an organopolysiloxane represented by an average unit formula; (B) an organopolysiloxane having 10 or less silicon atoms, wherein 30 to 60 mole % of all silicon atom-bonded organic groups are alkenyl groups having from 2 to 6 carbons; (C) an organopolysiloxane represented by a general formula; (D) an organopolysiloxane having at least 2 silicon atom-bonded hydrogen atoms in a molecule, wherein the content of phenyl groups in all silicon atom-bonded organic groups in this component is at least 20 mole %; (E) an organopolysiloxane having at least 2 silicon atom-bonded hydrogen atoms in a molecule, wherein the content of phenyl groups in all silicon atom-bonded organic groups in this component is less than 20 mole %; (F) a hydrosilylation reaction catalyst; (G) a white pigment; and (H) an inorganic filler other than a white pigment, has excellent formability for forming a cured product that has little discoloration and lowering of mechanical strength by heat and light, has high light reflectance, has excellent dimensional stability, and is capable of good attachment by a sealing agent used for an optical semiconductor device.

Owner:DOW CORNING TORAY CO LTD

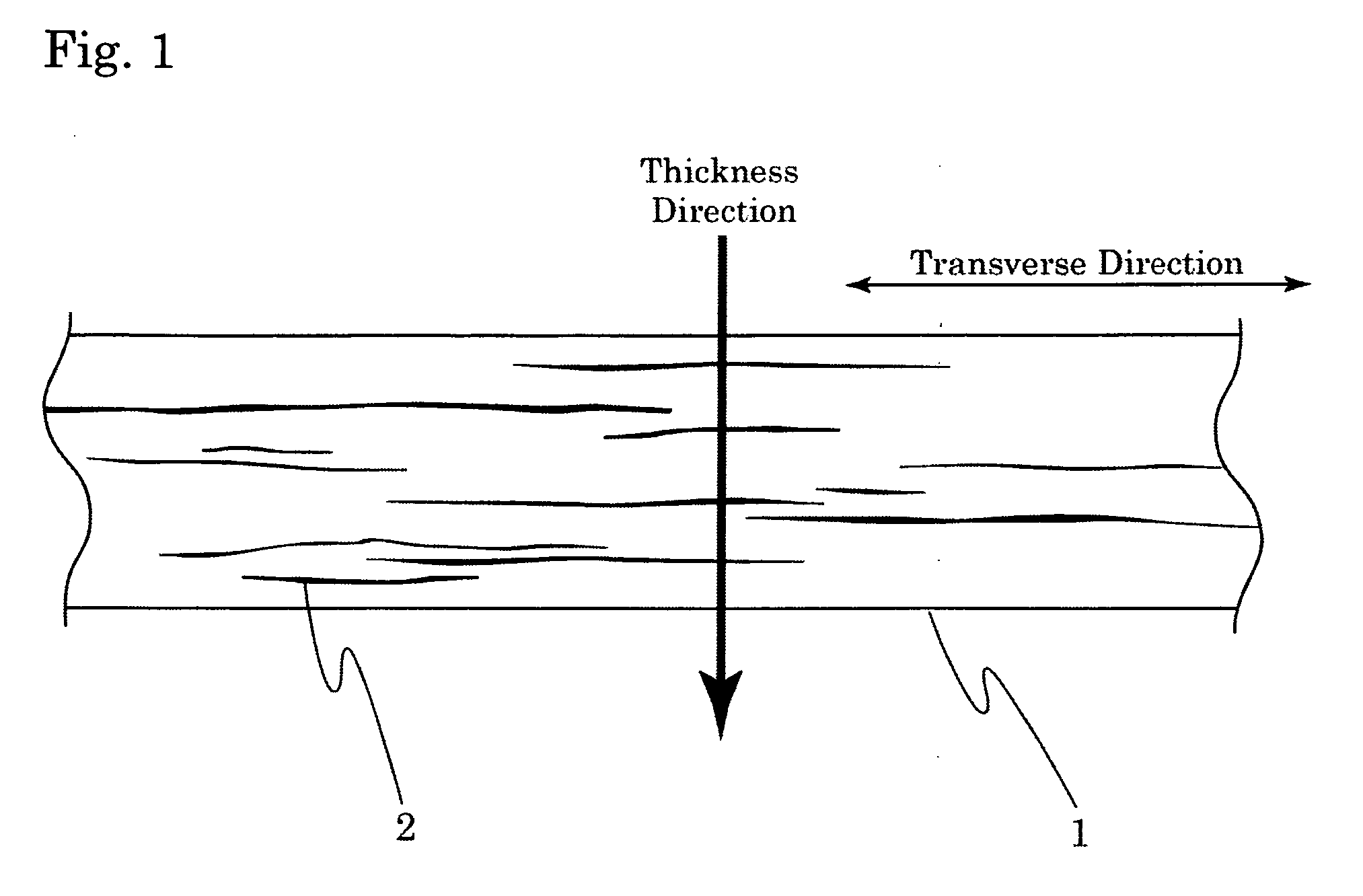

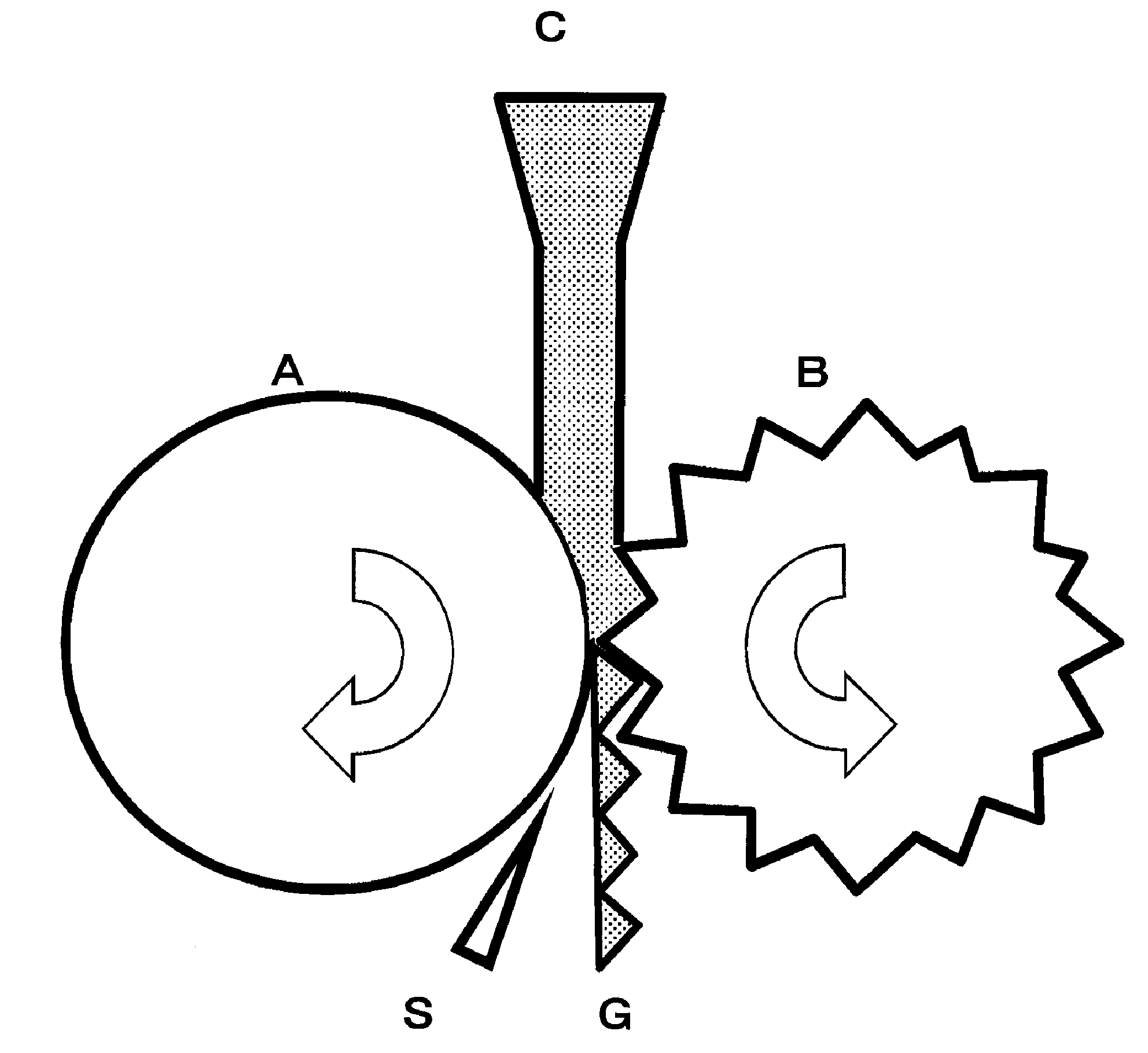

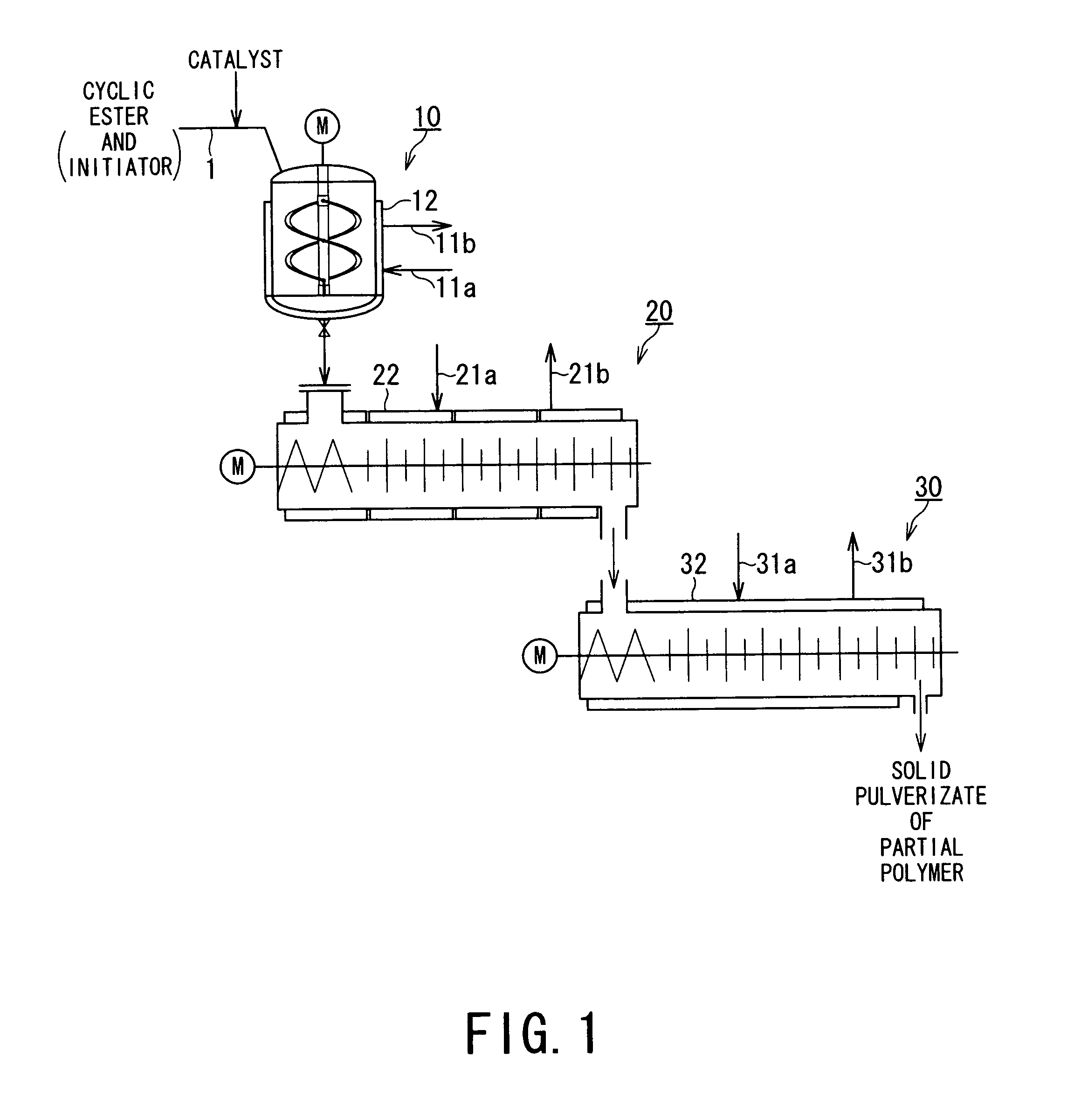

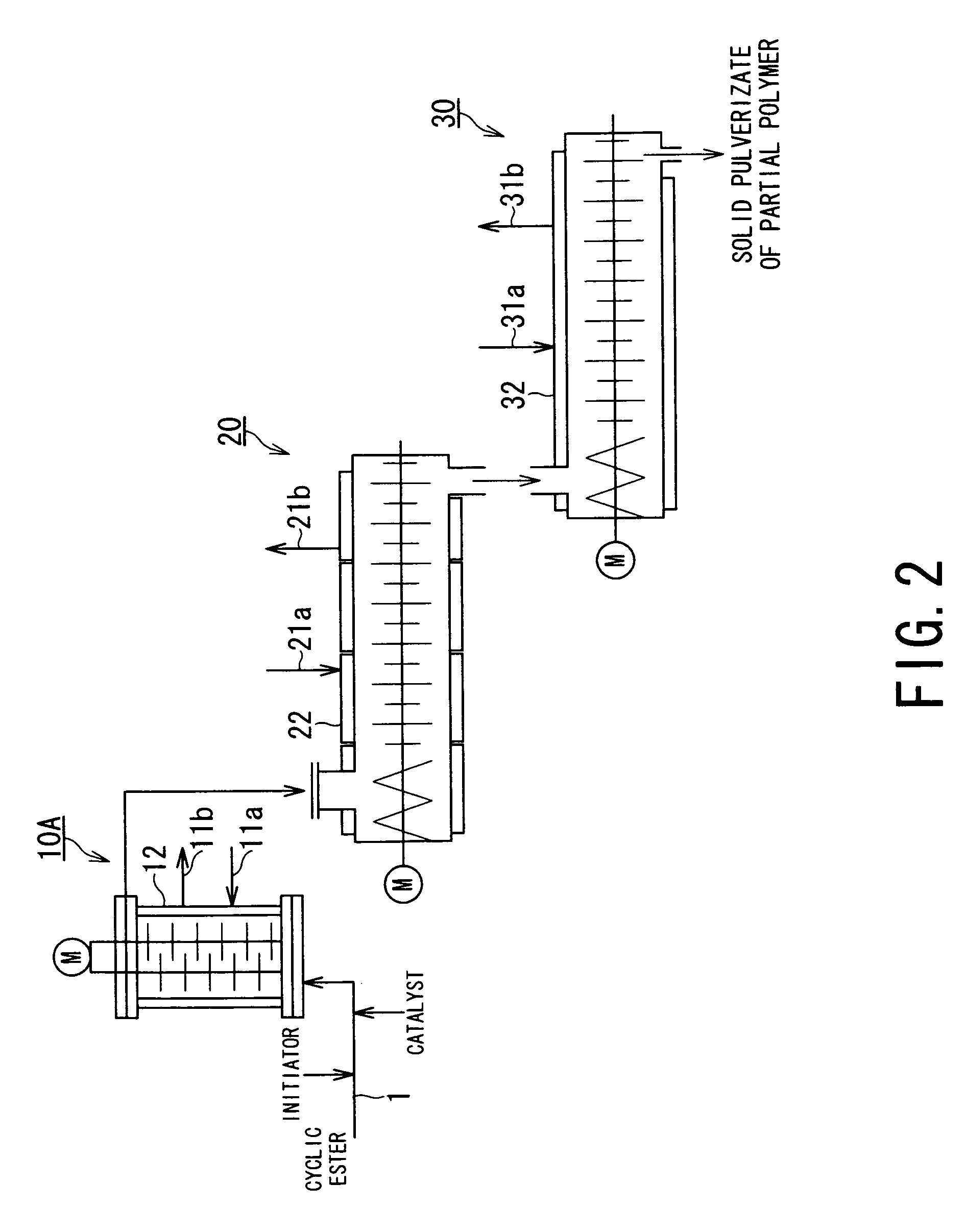

Process for producing aliphatic polyester

ActiveUS8580914B2High molecular weightLittle discolorationChemical/physical/physico-chemical stationary reactorsMolten statePolyester

A process for producing an aliphatic polyester through ring-opening polymerization of a cyclic ester, wherein a partial polymer in a molten state is continuously introduced into a twin-screw stirring device to continuously obtain a partial polymer in a solid pulverized state, the partial polymer is subjected to solid-phase polymerization, and the resultant polymer is melt-kneaded together with a thermal stabilizer to be formed into pellets. As a result, an aliphatic polyester of a high molecular weight and with little discoloration is produced efficiently.

Owner:KUREHA KAGAKU KOGYO KK

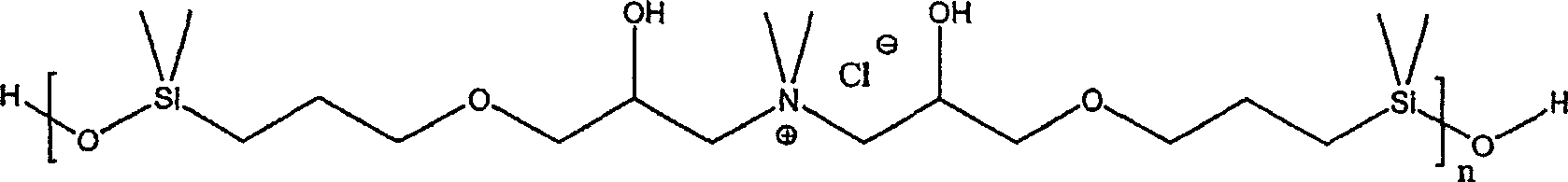

Cross-linkable products based on organosilicon compounds

The invention relates to cross-linkable products based on organosilicon compounds and exhibiting biostatic properties and to a method for the production and use thereof, wherein the inventive cross-linkable products contain organosilicon compounds of quaternary ammonium groups.

Owner:WACKER CHEM GMBH

Curable silicone composition, cured product thereof, and optical semiconductor device

InactiveUS9045641B2Little discoloration and lowering of mechanical strengthImprove reflectivitySolid-state devicesSemiconductor devicesPolymer scienceHydrosilylation

A curable silicone composition comprises: (A) an organopolysiloxane represented by an average unit formula; (B) an organopolysiloxane having 10 or less silicon atoms, wherein 30 to 60 mole % of all silicon atom-bonded organic groups are alkenyl groups having from 2 to 6 carbons; (C) an organopolysiloxane represented by a general formula; (D) an organopolysiloxane having at least 2 silicon atom-bonded hydrogen atoms in a molecule, wherein the content of phenyl groups in all silicon atom-bonded organic groups in this component is 20 to 70 mole %; (E) an organopolysiloxane represented by an average unit formula; (F) a hydrosilylation reaction catalyst; (G) a white pigment; and (H) an inorganic filler other than a white pigment, has excellent formability for forming a cured product that has little discoloration and lowering of mechanical strength by heat and light, has high light reflectance, has excellent dimensional stability, and is capable of good attachment by a sealing agent used for an optical semiconductor device.

Owner:DOW CORNING TORAY CO LTD

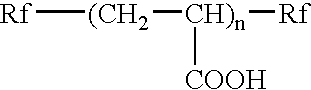

Method for producing fluorine-containing polymer, aqueous dispersion of fluorine-containing polymer,2-acyloxycarboxylic acid derivative, and surface active agent

ActiveUS7569631B2Reduce contentGood physical propertiesOrganic chemistrySynthetic resin layered productsAcid derivativeCarboxylic salt

The present invention provides a method of producing a fluoropolymer, wherein polymerization using a carboxylate ester bond-containing carboxylic acid derivative as a surfactant in an aqueous medium to give the fluoropolymer is conducted, the above carboxylate ester bond-containing carboxylic acid derivative has a carboxylate ester bond and —COOM (M representing H, NH4, Li, Na or K), the above carboxylate ester bond may optionally be substituted by fluorine atom.

Owner:DAIKIN IND LTD

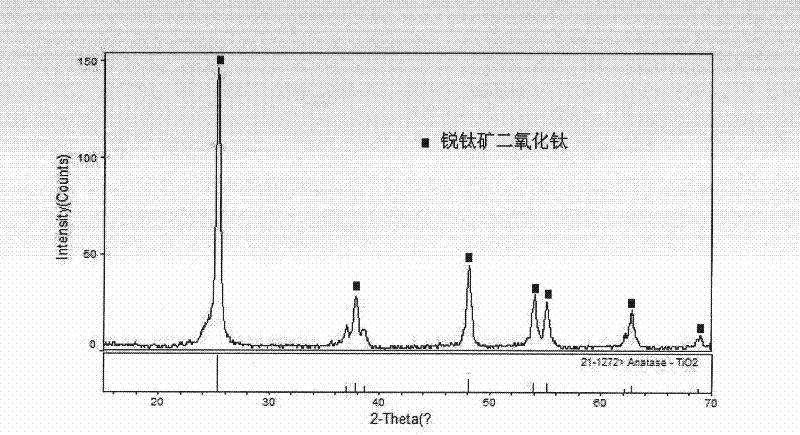

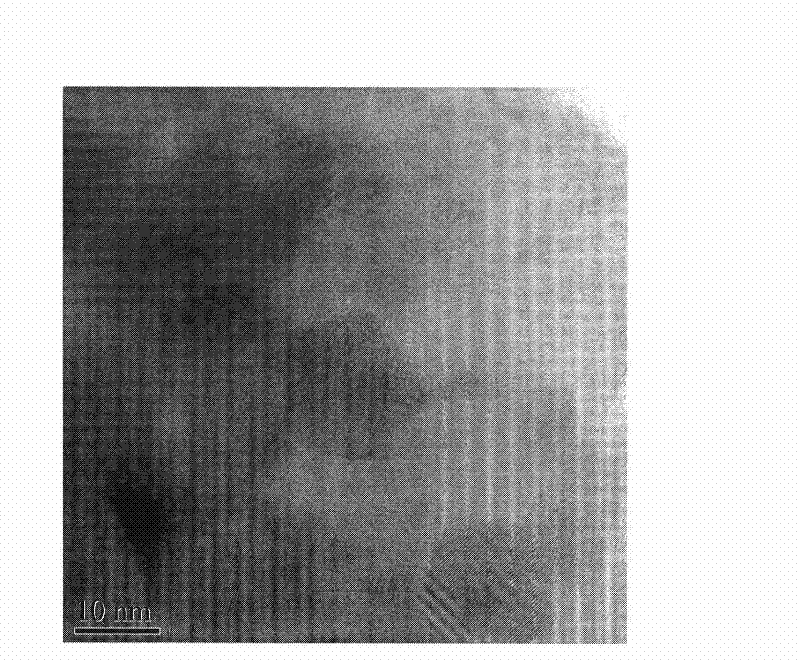

Method for preparing anatase nano Ag/TiO2 composite material

ActiveCN101972653BReduce the degree of oxidative discolorationLittle discolorationCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsMagnetic stirrerAmmonia

The invention relates to a method for preparing an anatase nano Ag / TiO2 composite material, which comprises the steps of: adding AgNO3 in stronger ammonia water, sealing a cup opening by using a preservative film, heating and stirring on a magnetic stirrer to ensure that the AgNO3 is fully dissolved, then adding C16H36O4Ti, and continuously stirring and heating to ensure that a solution gradually changes into an opaque milky solution; continuously stirring and heating until the solution is dried up to obtain white solid; and placing the white solid together with a beaker into a drying oven to be dried, and grinding into powder; and sintering the powder in a muffle furnace to obtain an anatase nano TiO2 crystal. Silver is loaded in a nano TiO2 solution, and is mixed more uniformly compared with the traditional method; a contact area of the silver and titanium dioxide is larger compared with the traditional method, the silver loading is not only carried out on the surface but also carried out in all nano titanium dioxide particles so that the oxidization discoloration degree of the silver is lowered, therefore, the method is very beneficial to the obtaining of the nano Ag / TiO2 withvery uniform dispersion of the silver, lower decoloration degree and strong catalysis activity and sterilizing property.

Owner:山东兴辰铝业科技有限公司

Spun-dyed meta-type wholly aromatic polyamide fiber

InactiveUS20140303292A1Little discolorationSmall shrinkageOrganic dyesMonocomponent synthetic polymer artificial filamentAramidesLight exposure

A spun-dyed meta-type wholly aromatic polyamide fiber with small discoloration and fading due to the light exposure, in which the content of the solvent remaining in the fiber is at a certain level or less. Specifically, a spun-dyed meta-type wholly aromatic polyamide fiber, in which the residual solvent content of the fiber is 0.1% by mass or less based on the whole mass of the fiber.

Owner:TEIJIN LTD

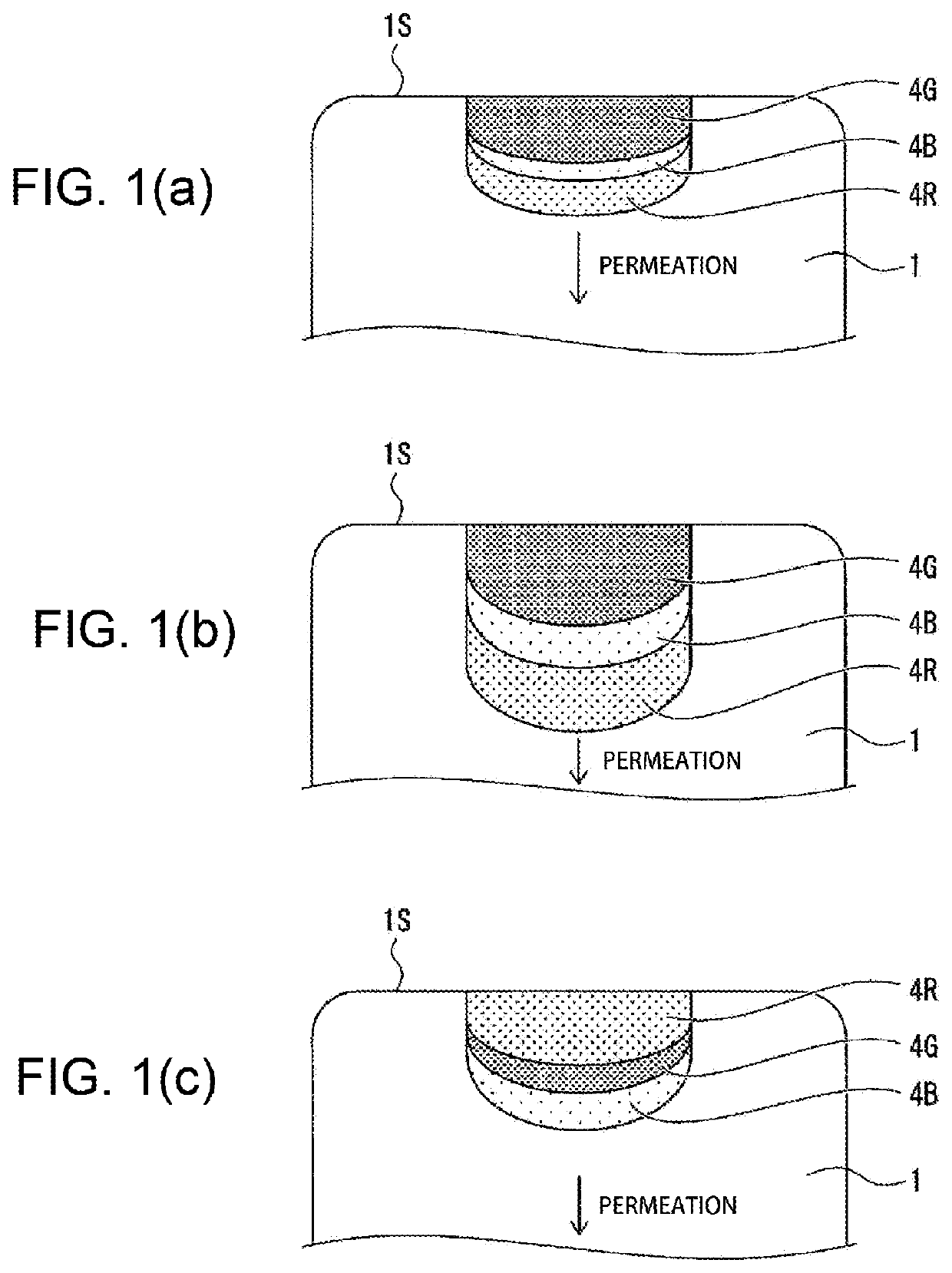

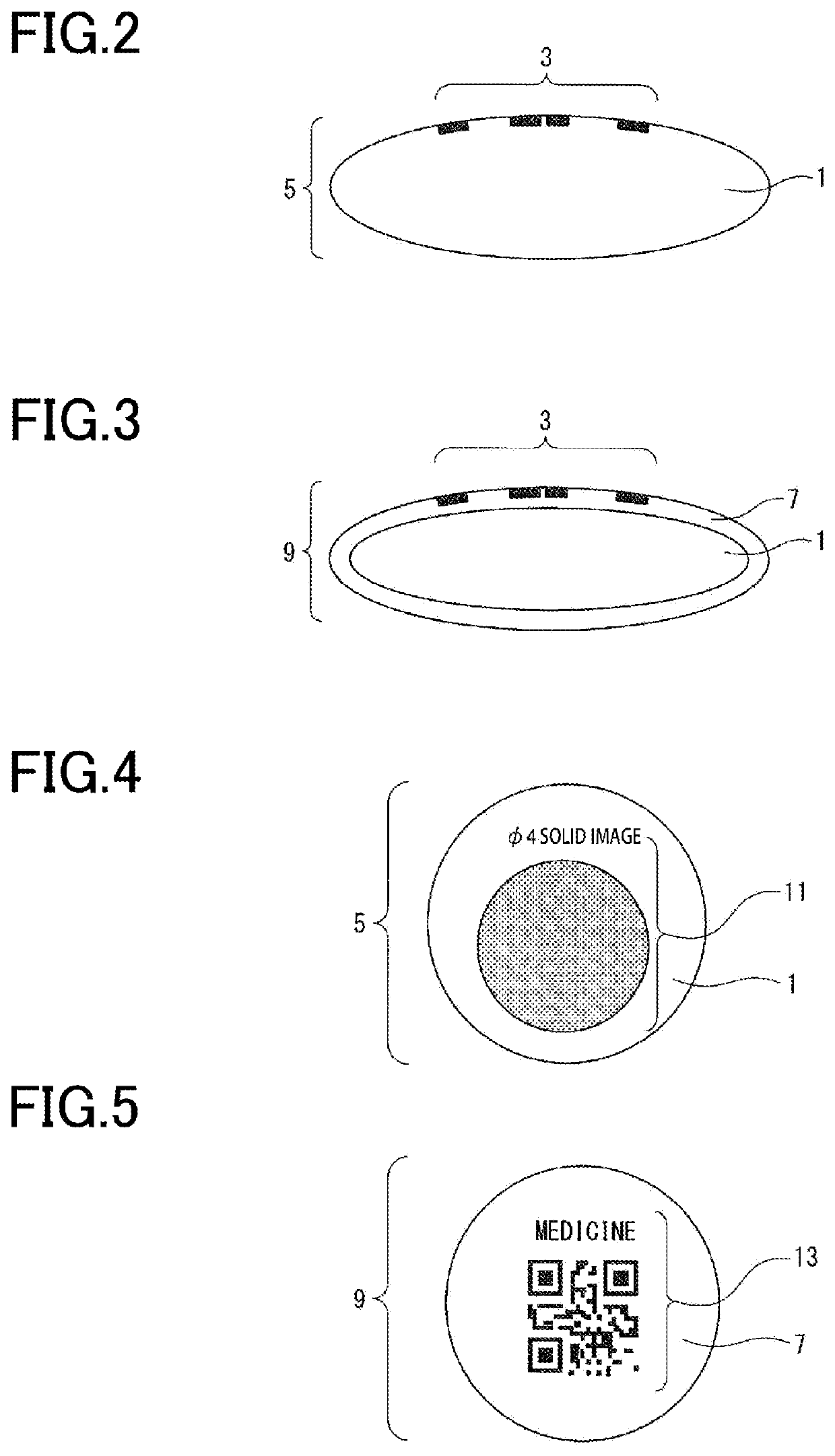

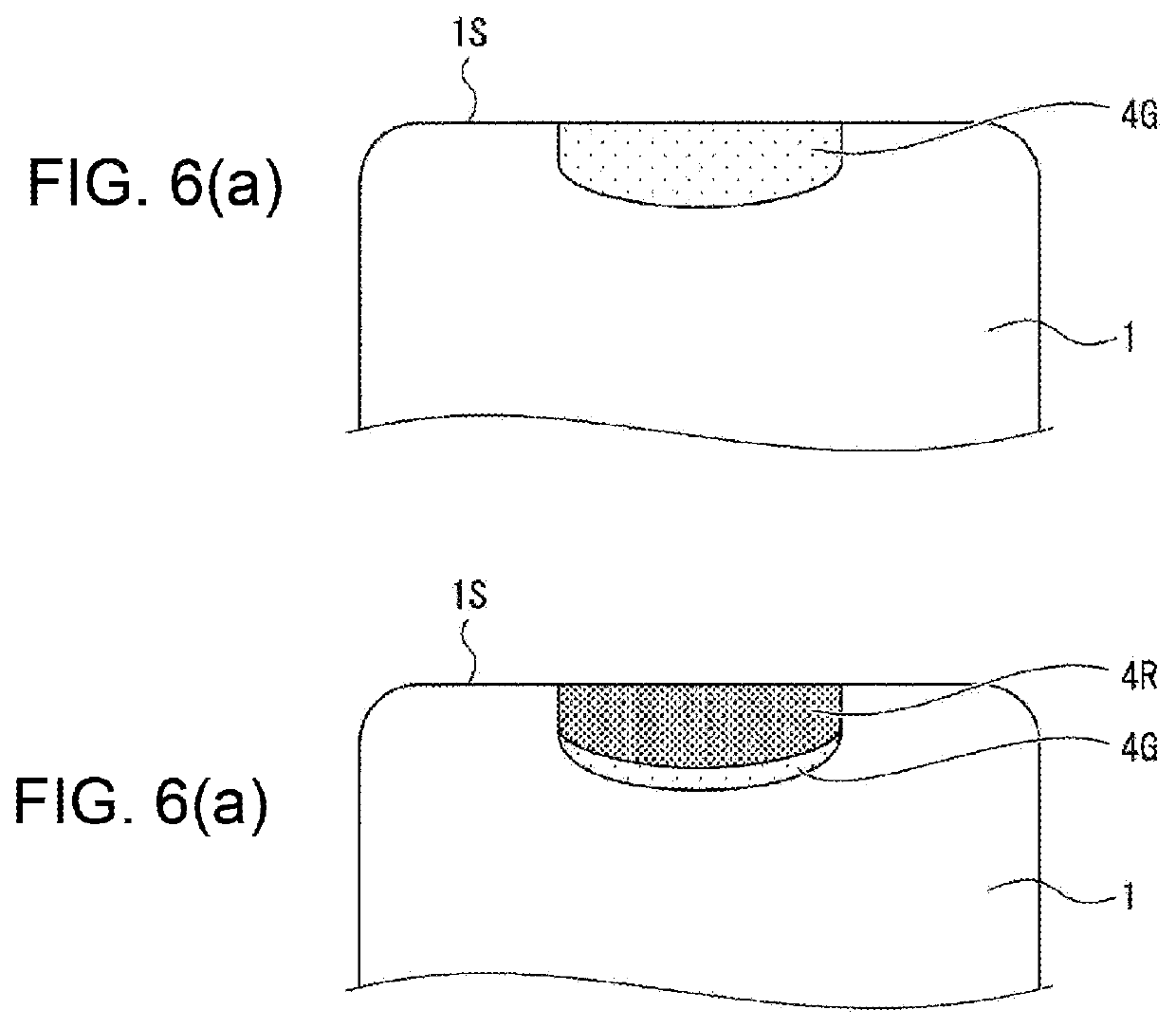

Inkjet ink and printed item

PendingUS20210380828A1Color stableReduce penetrationDuplicating/marking methodsInksFood coloringColoring agents

Owner:TOPPAN PRINTING CO LTD

Fluorine-containing resin film and solar cell module

ActiveUS9337012B2Little discolorationWeather resistance and size stabilitySynthetic resin layered productsSemiconductor/solid-state device manufacturingMethacrylateX-ray

Owner:DENKA CO LTD

Fluorine-containing resin film and solar cell module

ActiveUS9373495B2Little discolorationWeather resistance and size stabilitySynthetic resin layered productsSemiconductor/solid-state device manufacturingMethacrylateX-ray

Owner:DENKA CO LTD

A kind of vacuum freeze-drying process of roses

ActiveCN111721073BImprove physical propertiesRealize the collectionDrying solid materials without heatPreliminary solid treatment for dryingFreeze-dryingJojoba oil

The invention discloses a process for vacuum freeze-drying roses, which comprises the following steps: S1 picking and processing roses; S2 treating roses with a color-preserving solution; S3 freeze-drying roses; S4 gradient heating and drying roses; dew; the beneficial effect of the present invention is: utilize color retention liquid and atomize color retention liquid, realize the collection and utilization of rose; Utilize jojoba oil, tartaric acid and almond oil, keep the stability of petal cell, simultaneously the three Combination and superposition of anti-oxidation properties stabilize the overall color of the petals and achieve full drying; use the three-stage temperature rise to realize collection and utilization; realize collection and utilization by limiting the conditions of low-temperature condensation collection; realize full drying by atomizing the color-preserving liquid; Let stand for 35 minutes to achieve full drying.

Owner:银谷芳香科技有限公司

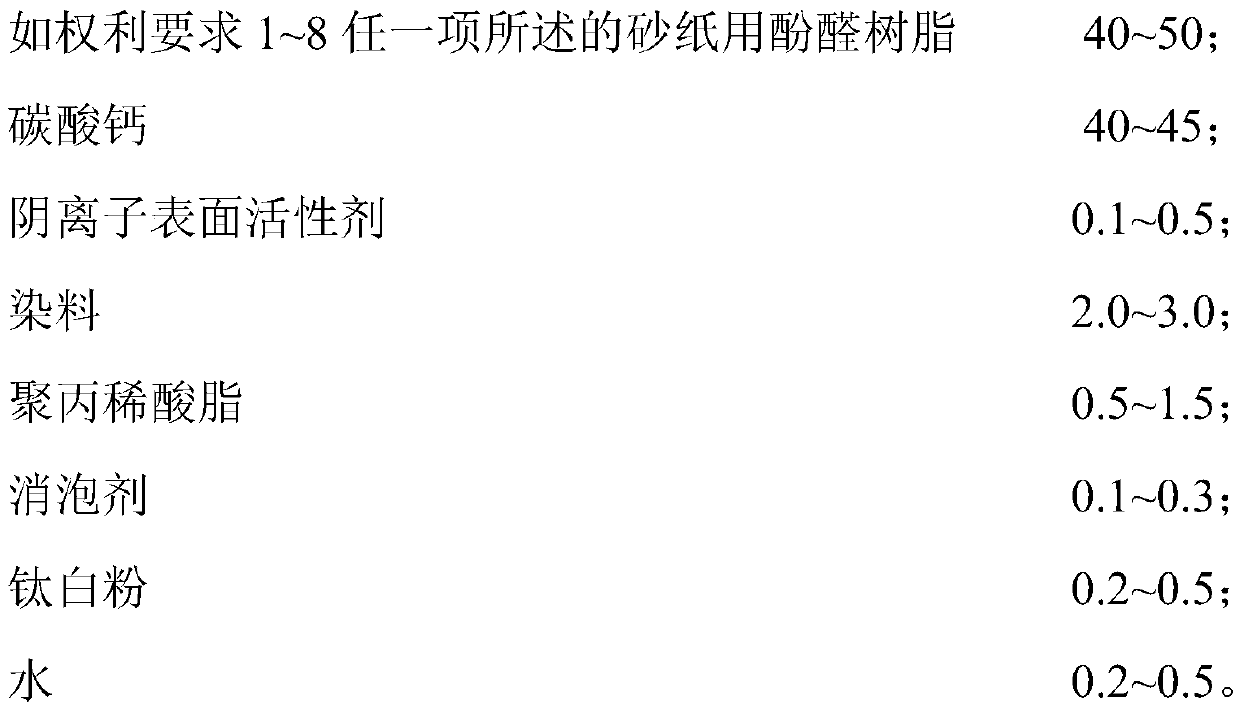

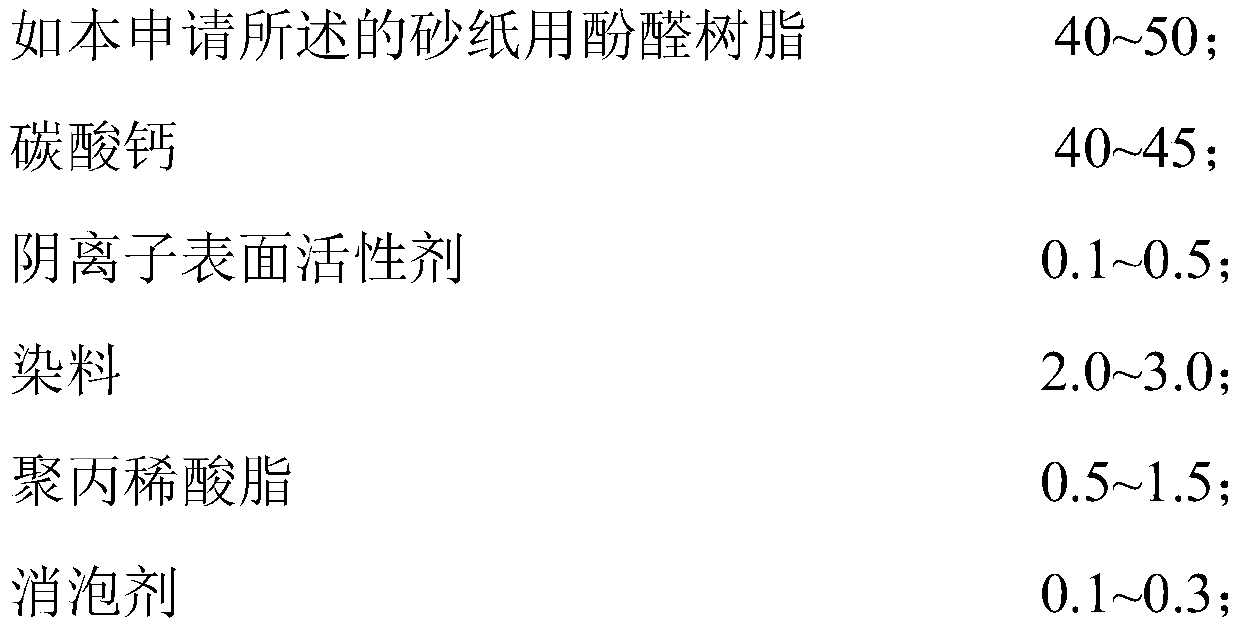

Phenolic resin for abrasive paper, preparation method of phenolic resin and compound gluefor abrasive paper

PendingCN111234152ALittle discolorationImprove grinding performanceAbrasion apparatusOrganic acidPolymer science

The invention provides a phenolic resin for abrasive paper, a preparation method of the phenolic resin and a compound glue for the abrasive paper. The phenolic resin comprises a first component and asecond component, the preparation method of the first component comprises the following steps: reacting phenol with an aldehyde in a nitrogen atmosphere at 80-90 DEG C for 1-3 hours under the action of an inorganic base catalyst to obtain a system A; adding a phenol into the system A, and reacting at 80-100 DEG C for 1-2 hours to obtain a system B; adjusting the temperature of the system B to 60-70 DEG C, adding an amino compound, and dehydrating to a preset viscosity to obtain the first component; the preparation method of the second component comprises the following steps: dissolving an organic acid in water and ethanol to obtain the second component; wherein the mass ratio of the first component to the second component is 1: (0.01-0.1). The phenolic resin is light in discoloration in the storage process, and the obtained abrasive paper is higher in abrasive resistance.

Owner:浙江自立高分子化工材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com