Soluble glassy antimicrobial agent and water-treatment agent

A water treatment agent and vitreous technology, applied in the field of antibacterial agents, can solve the problems of low antibacterial effect of zinc, change of dissolution rate, easy cracking of glass, etc., and achieve excellent water permeability, high antibacterial performance, attenuation and discoloration small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

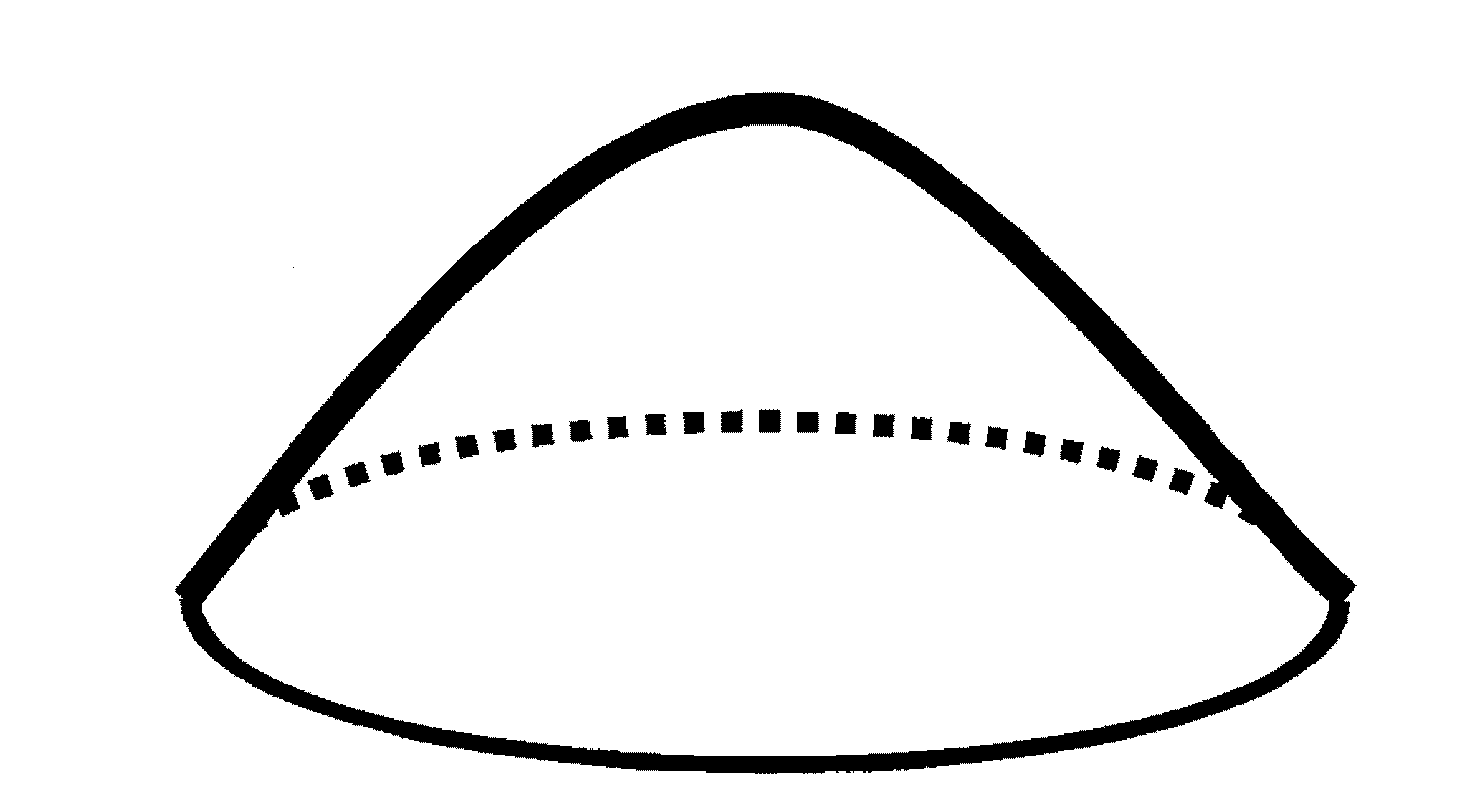

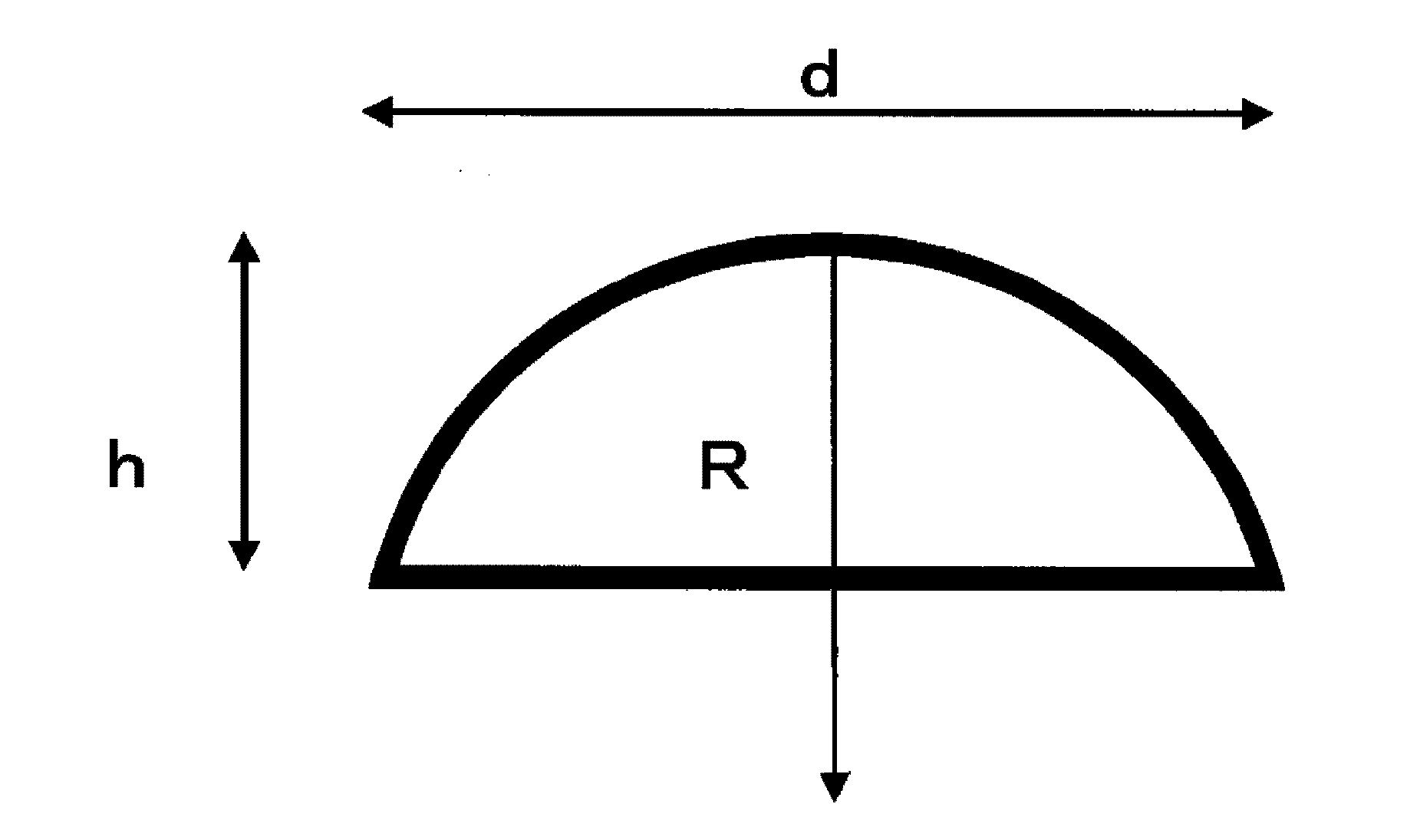

[0067] The glass raw material formulations which consisted of the composition of Examples 1-7, 9, and 10 shown in Table 1 were heat-melted at 1200 degreeC. After melting, cooling and molding were performed using a metal cooling molding roll with a hemispherical depression of 5 mm in diameter arranged on one side, and the resulting glass was crushed by beating with a ball mill, and further dry crushed for 1 hour, and then, A wire mesh with a mesh size of 2.8mm sieves and drops the fine powder to obtain Examples 1 to 7, 9, and 10 of the water treatment agent. Table 2 shows the average mass, size, eluted silver concentration, and fillability using an automatic filling machine of 10 arbitrary grains of the obtained water treatment agent evaluated.

[0068] The bottoms of the water treatment agents obtained in Examples 1 to 7, 9, and 10 are planar hemispherical, and the maximum diameter D of the bottoms of each 10 grains is measured with a vernier caliper, and its average number is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com