Durable flame-retardant, water-repellent, waterproof and moisture permeable finishing method of polyester fabric

A polyester fabric and water-repellent finishing technology, which is applied in the field of waterproof and moisture-permeable coating finishing, water-repellent, polyester filament Oxford cloth, and durable flame-retardant polyester fabric. It can solve the problems of unmentioned water-repellent grade and achieve durability water repellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

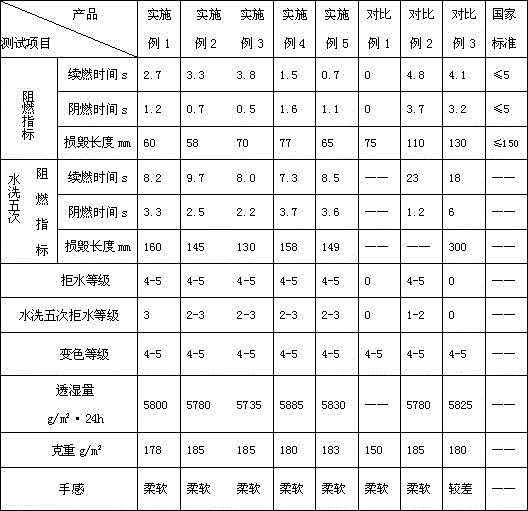

Examples

Embodiment 1

[0048] Cyclic phosphate flame retardant 20 parts

[0049] 60 parts of water

[0050] 1 part isocyanate crosslinker

[0051] Fluorocarbon copolymer water repellent 3 parts

[0052] Mass concentration 10% NaOH 2 parts

[0053] The above raw materials are mixed and stirred evenly according to the above sequence, and the pH value of the finishing solution is adjusted to 5.5.

Embodiment 2

[0055] Cyclic phosphate flame retardant 23 parts

[0056] 62 parts of water

[0057] Isocyanate crosslinking agent 1.2 parts

[0058] Fluorocarbon copolymer waterproofing agent 3.5 parts

[0059] Mass concentration 10% NaOH 3 parts

[0060] The above raw materials are mixed and stirred evenly according to the above sequence, and the pH value of the finishing solution is adjusted to 6.0.

Embodiment 3

[0062] Cyclic phosphate flame retardant 25 parts

[0063] 64 parts of water

[0064] Isocyanate crosslinking agent 1.3 parts

[0065] Fluorocarbon copolymer water repellent 4 parts

[0066] Mass concentration 10% NaOH 4 parts

[0067] The above raw materials are mixed and stirred evenly according to the above sequence, and the pH value of the finishing solution is adjusted to 6.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com