Fireproof flame-retardant composite PVC floor

A fire-resistant, flame-retardant, composite technology, applied in floor coverings, synthetic resin layered products, applications, etc., can solve problems such as complex structure, poor wear resistance, and grooves caused by sharp and heavy objects, achieving high safety, Long service life and increased aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]In order to deepen the understanding of the present invention, the present invention will be further detailed in connection with the embodiments and the accompanying drawings, which is not intended to be construed as limiting the scope of the invention.

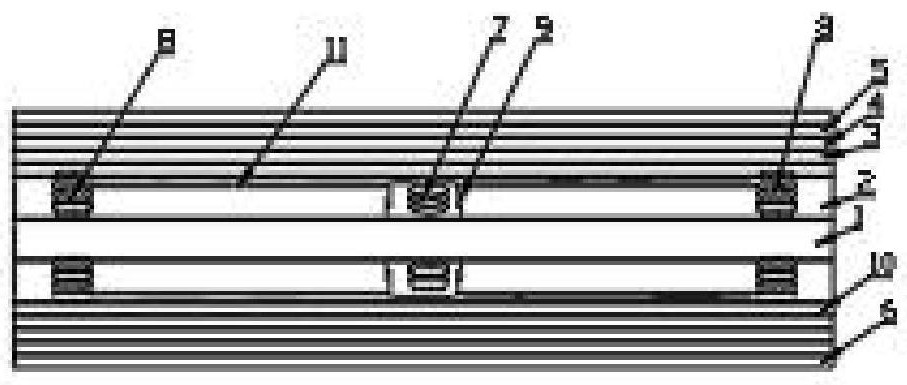

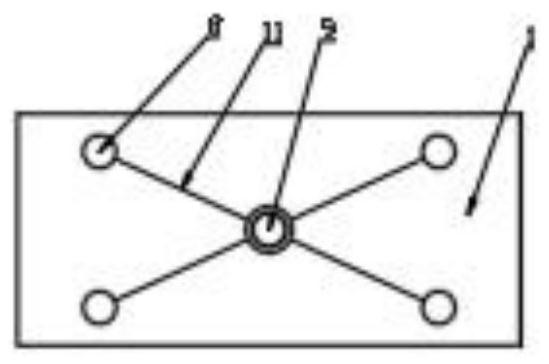

[0017]Such asfigure 1 As shown, a fire flame retardant composite PVC floor includes a substrate 1, a spring protective layer 2, a moisture-proof layer 3, a waterproof layer 4, a color film layer 5, a flame retardant layer 6, a spring 7, 2 The spring 8, the sleeve 9, the fire flame retardant layer 10, and the connecting rod 11.

[0018]A fire flame retardant composite PVC floor comprising a substrate 1 and a spring protective layer 2, and a fixed sleeve 9 is provided in the middle of the upper surface of the base layer 1, and a spring 7 is provided in the sleeve 9. A spring 8 is provided with a second spring 8 at the upper surface of the upper surface of the material 1, and the second spring 8 is connected to the sleeve 9, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com