Coating for indoor decoration and preparation method

A technology for interior decoration and coatings, applied in the field of interior decoration coatings and manufacturing methods, can solve the problems of affecting the original performance of materials, easily polluting the environment and human body, and affecting the color and light of objects, etc., achieve excellent chemical stability, facilitate popularization and application, and prepare The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

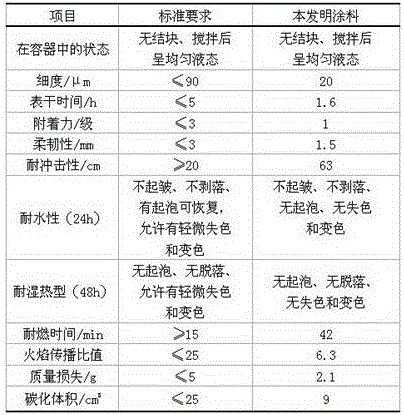

Examples

Embodiment 1

[0027] Example 1 A paint for interior decoration, prepared from the following raw materials, all in parts by weight (5.5kg / part): 23.0 parts of amino resin, 4.3 parts of bauxite, 3.5 parts of benzyl alcohol, and 2.8 parts of rosin ester , 4.9 parts of tertiary vinegar emulsion, 2.1 parts of chrome yellow, 5.6 parts of high alumina cement, 7.3 parts of calcium carbonate, 2.2 parts of ethylene glycol, 3.6 parts of stearic acid.

[0028] A kind of preparation method for the coating of interior decoration is:

[0029] (1) Soften the amino resin at 120°C for 40 minutes, then place it in a pulverizer with the rosin ester and pulverize it to obtain pulverized material for later use;

[0030] (2) Mix bauxite, high alumina cement, stearic acid and calcium carbonate, grind in a ball mill, pass through a 160-mesh sieve, add ethylene glycol, tertiary vinegar emulsion and benzyl alcohol, and mix and stir at 60°C for 20 minutes ,spare;

[0031] (3) Put the raw materials treated in steps (...

Embodiment 2

[0033] Example 2 A coating for interior decoration, prepared from the following raw materials, all in parts by weight (3.5kg / part): 27.0 parts of amino resin, 5.8 parts of bauxite, 4.6 parts of benzyl alcohol, and 3.6 parts of rosin ester , 5.8 parts of tertiary vinegar emulsion, 3.2 parts of chrome yellow, 6.8 parts of high alumina cement, 8.6 parts of calcium carbonate, 2.8 parts of ethylene glycol, and 4.7 parts of stearic acid.

[0034] A kind of preparation method for the coating of interior decoration is:

[0035] (1) Soften the amino resin at 160°C for 70 minutes, then place it in a pulverizer with the rosin ester and pulverize it to obtain pulverized material for later use;

[0036] (2) Mix bauxite, high alumina cement, stearic acid and calcium carbonate, grind in a ball mill, pass through a 220-mesh sieve, add ethylene glycol, tertiary vinegar emulsion and benzyl alcohol, and mix and stir at 90°C for 40 minutes ,spare;

[0037] (3) Put the raw materials treated in s...

Embodiment 3

[0039]Example 3 A coating for interior decoration, prepared from the following raw materials, all in parts by weight (5kg / part): 24.0 parts of amino resin, 4.8 parts of bauxite, 3.8 parts of benzyl alcohol, 3.0 parts of rosin ester, 5.2 parts of tertiary vinegar emulsion, 2.4 parts of chrome yellow, 6.0 parts of high alumina cement, 7.6 parts of calcium carbonate, 2.4 parts of ethylene glycol, and 4.0 parts of stearic acid.

[0040] A kind of preparation method for the coating of interior decoration is:

[0041] (1) Soften the amino resin at 130°C for 50 minutes, then place it in a pulverizer with the rosin ester and pulverize it to obtain pulverized material for later use;

[0042] (2) Mix bauxite, high alumina cement, stearic acid and calcium carbonate, grind in a ball mill, pass through a 180-mesh sieve, add ethylene glycol, tertiary vinegar emulsion and benzyl alcohol, and mix and stir at 70°C for 25 minutes ,spare;

[0043] (3) Put the raw materials treated in steps (1)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com