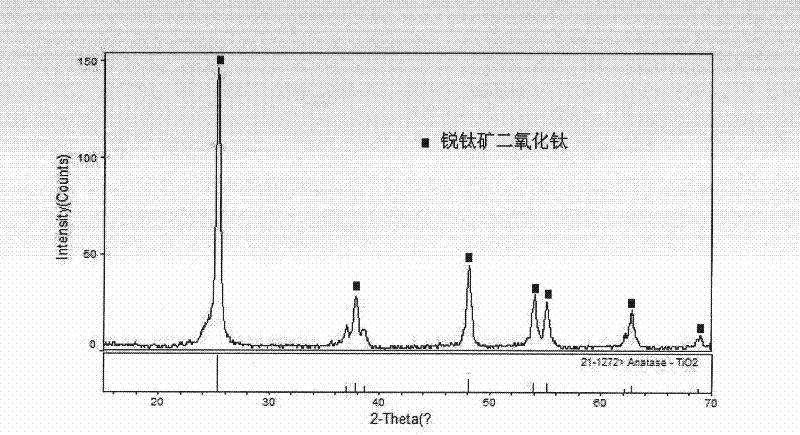

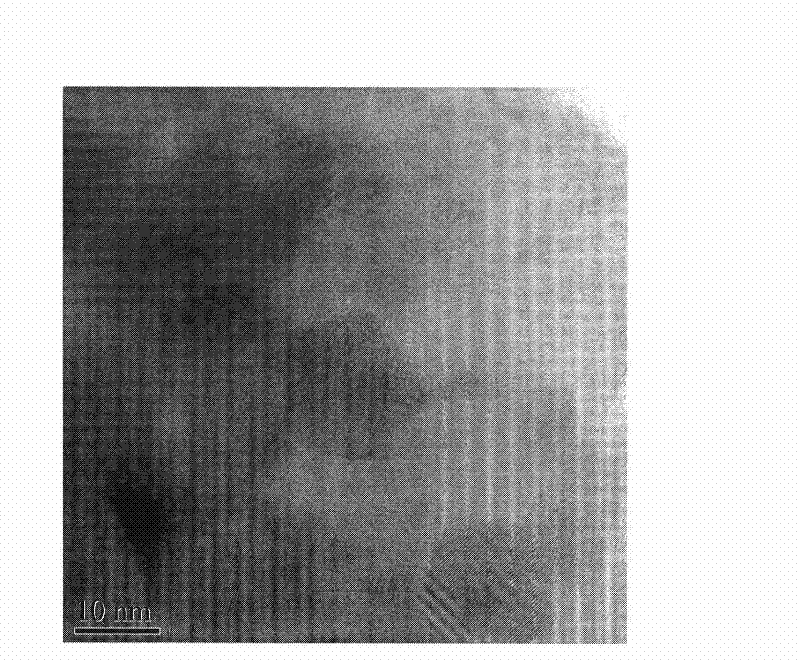

Method for preparing anatase nano Ag/TiO2 composite material

An anatase type, composite material technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high production cost, complicated process, complicated and difficult to control process, and achieve The effect of reduced production cost, simple process, strong catalytic activity and bactericidal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1) Take 20ml mass percent of 25% concentrated ammonia in a beaker, mix AgNO with 1% doping amount 3 Add concentrated ammonia water, seal the mouth of the cup with plastic wrap, heat and stir on a magnetic stirrer to make AgNO 3 completely dissolved;

[0017] 2) When the solution obtained in step 1) is heated until the remaining amount is 15ml, add 5ml of C 16 h 36 o 4 Ti, continue stirring and heating, the solution gradually becomes milky white opaque solution;

[0018] 3) Remove the plastic wrap, continue stirring and heating until the solution is evaporated to dryness, and a white solid is obtained;

[0019] 4) Place the white solid together with the beaker in an oven at 100°C for 30 minutes and then grind it finely to obtain a powder;

[0020] 5) Sinter the above powder in a muffle furnace at 200°C for 2 hours to remove nitrogen-containing substances and water remaining in the crystal, and then sinter in a muffle furnace at 550°C for 3 hours to further crystalli...

Embodiment 2

[0022] 1) Get 20ml of concentrated ammonia water with a mass percentage of 25% in a beaker, and mix AgNO with a doping amount of 3%. 3 Add concentrated ammonia water, seal the mouth of the cup with plastic wrap, heat and stir on a magnetic stirrer to make AgNO 3 completely dissolved;

[0023] 2) When the solution obtained in step 1) is heated until the remaining amount is 15ml, add 5ml of C 16 h 36 o 4 Ti, continue stirring and heating, the solution gradually becomes milky white opaque solution;

[0024] 3) Remove the plastic wrap, continue stirring and heating until the solution is evaporated to dryness, and a white solid is obtained;

[0025] 4) Place the white solid together with the beaker in an oven at 100°C for 50 minutes and then grind it finely to obtain a powder;

[0026] 5) Sinter the above powder in a muffle furnace at 200°C for 2 hours to remove nitrogen-containing substances and water remaining in the crystal, and then sinter in a muffle furnace at 550°C for ...

Embodiment 3

[0028] 1) Take 20ml mass percent of 25% concentrated ammonia in a beaker, and mix AgNO with 5% doping amount 3 Add concentrated ammonia water, seal the mouth of the cup with plastic wrap, heat and stir on a magnetic stirrer to make AgNO 3 completely dissolved;

[0029] 2) When the solution obtained in step 1) is heated until the remaining amount is 15ml, add 5ml of C 16 h 36 o 4Ti, continue stirring and heating, the solution gradually becomes milky white opaque solution;

[0030] 3) Remove the plastic wrap, continue stirring and heating until the solution is evaporated to dryness, and a white solid is obtained;

[0031] 4) Place the white solid together with the beaker in an oven at 100°C for 40 minutes and then grind it finely to obtain a powder;

[0032] 5) Sinter the above powder in a muffle furnace at 200°C for 2 hours to remove nitrogen-containing substances and water remaining in the crystal, and then sinter in a muffle furnace at 550°C for 3 hours to further crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com