A method for partition cooling the oven room of food workshop

An oven room and partition technology, which is applied in the field of partition cooling of the oven room in the food workshop, can solve the problems of adverse effects on the production environment and sanitation products in the workshop, and achieve the effects of improving the environment, prolonging the discoloration time, and maintaining comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

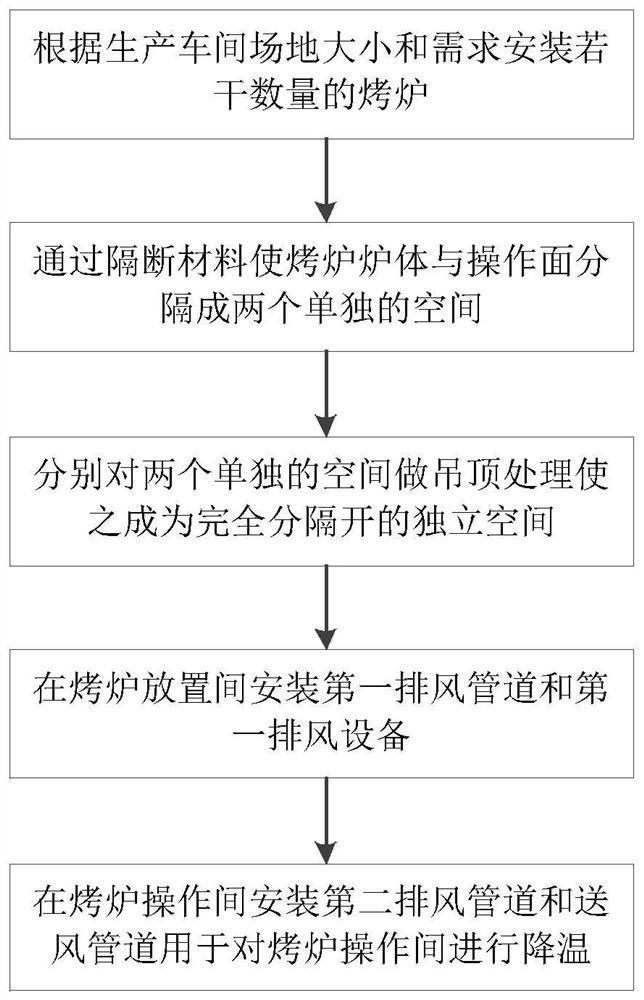

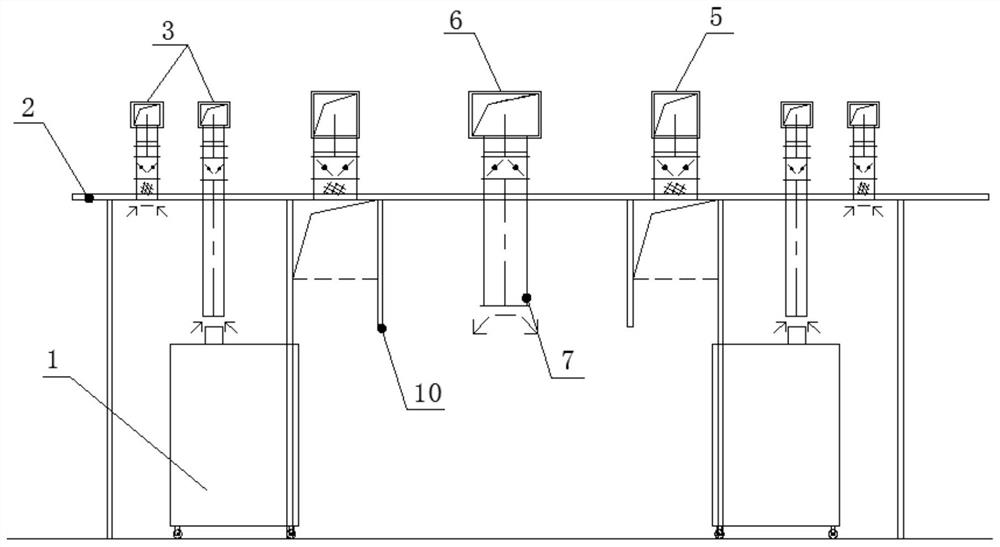

[0035] like figure 1 As shown, a method for partition cooling the oven room of a food workshop comprises the following steps:

[0036] (S1) Install a certain number of ovens 1 according to the size and demand of the production workshop;

[0037] (S2) separating the oven body and the oven operation surface with a partition material 2 along the oven operation surface, and forming two separate spaces;

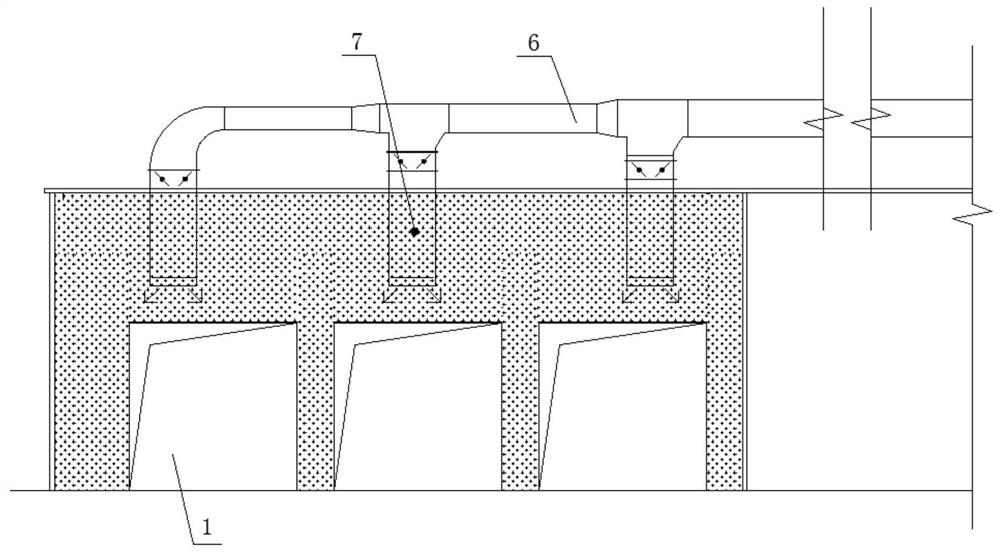

[0038] (S3) Suspend the ceiling of two separate spaces to form an oven placement room mainly based on the oven body and an oven operation room mainly on the oven operating surface, and the oven placement room is connected with the oven operation The room is two completely independent spaces;

[0039] (S4) According to the heat emitted by all the ovens in the oven placement room and the amount of exhaust gas, the first exhaust duct 3 and the first exhaust equipment 4 of corresponding size are configured for ventilation and exhaust;

[0040] (S5) Install a second exhaust duct 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com