Novel ingot casting crucible and manufacturing method thereof

A technology of casting ingots and crucibles, which is applied in the field of solar cell crystal silicon wafer preparation, to achieve the effects of inhibiting the formation of polycrystalline corners, improving purity, and reducing the production ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing silicon dioxide slurry, the specific components of which are ultrapure water, silica sol, adhesive, and high-purity silicon dioxide. The preparation of the slurry is as follows: ultrapure water, silica sol, binder, high-purity silica (purity is 99.999%, particle size is 80-120 mesh) and the above raw materials are in a weight ratio of 5:1:0.5:3.5 After counterweighting, first put ultrapure water, silica sol, and adhesive into the mixer and stir evenly for 30 minutes to form a stable suspension, then add high-purity silica particles and stir evenly for 30 minutes before standing for later use .

[0025] When spraying the slurry, the process parameters are as follows: the spray gun pressure is 0.4-0.8MPa, the spraying temperature is 80°C, the drying temperature after spraying is 120°C hot air drying, and the time is 30min.

[0026] The proportion of silica sol and adhesive can fluctuate depending on the process level.

Embodiment 2

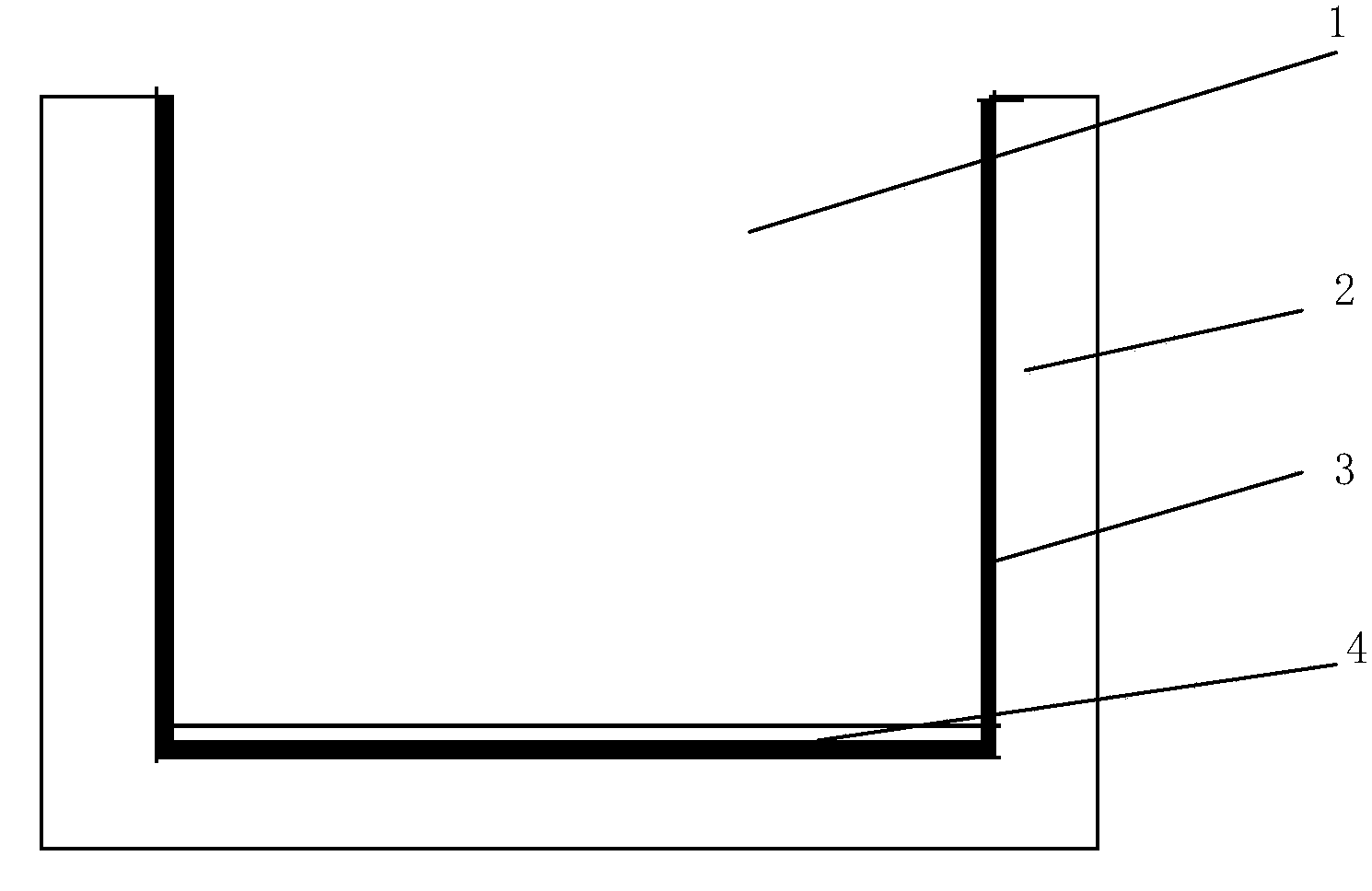

[0028] Select an ordinary G5 ingot crucible (1), and spray silicon nitride on the inner wall (2) (including the bottom surface and side wall) of the crucible according to the normal process. The thickness of the silicon nitride coating (3) is 200 μm. After drying and forming a film, Spray coating of high-purity silica coating (4) on the silicon nitride coating (including the bottom surface and side walls of the crucible), the particle size of the silica in the high-purity silica slurry is 180 mesh, and the silica The thickness of the sprayed layer is 180 μm, and a new high-efficiency crucible can be obtained after drying.

Embodiment 3

[0030] Select an ordinary G5 ingot crucible (1), and spray silicon nitride on the inner wall (2) (including the bottom surface and side wall) of the crucible according to the normal process. The thickness of the silicon nitride coating (3) is 200 μm. After drying and forming a film, A high-purity silicon dioxide coating (4) is sprayed on the silicon nitride coating on the bottom surface of the crucible.

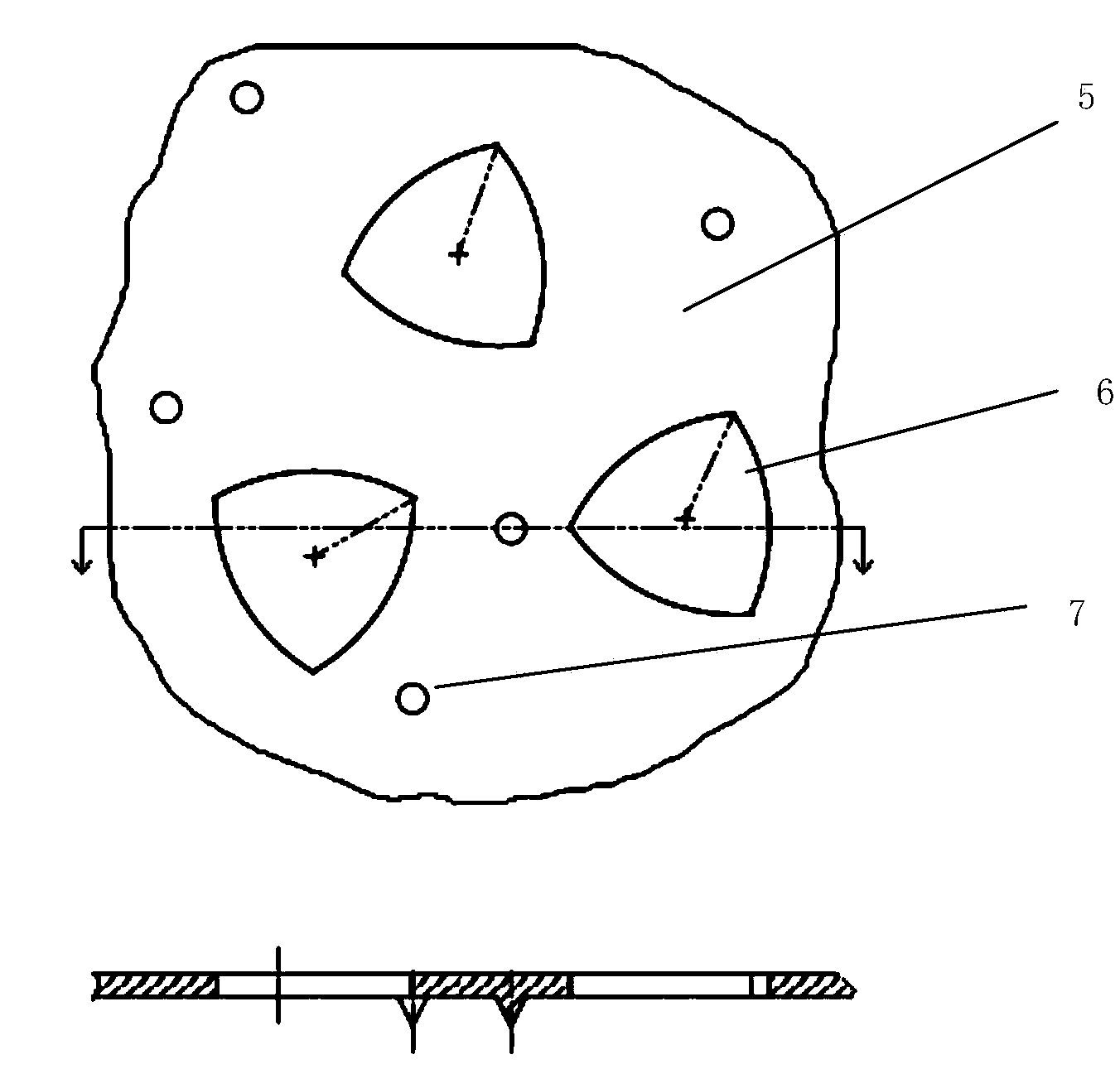

[0031] On the bottom surface of the crucible that has sprayed and dried the silicon nitride coating, put a spray template (5) that is processed with a geometric figure (6), and the bottom of the template has a conical protrusion (7) for supporting the template, and then silicon dioxide For slurry spraying, the particle size of high-purity silica is 160 mesh, and the thickness of the silica spray layer is 180 μm. After drying, a new type of high-efficiency crucible with geometric figures and concave-convex structures on the bottom surface can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com