Precoated sand for casting and preparation method thereof

A technology of coated sand and raw sand, which is applied to casting molding equipment, casting molds, manufacturing tools, etc., can solve problems such as easy deformation, achieve the effects of increasing strength, reducing consumption, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Thermal reclaimed sand is 40 / 70 mesh, Baozhu sand is 50 / 30 mesh, Baozhu sand accounts for 30% of the original sand weight, thermal reclaimed sand accounts for 70% of the original sand weight, the adhesive is 2% of the original sand weight, and the curing agent is 40% of the weight of the adhesive, the coupling agent is 0.5% of the weight of the adhesive, the lubricant is 40% of the weight of the adhesive, and the plasticizer is 5% of the weight of the adhesive.

[0031] Start the machine → preheat the raw sand to 138°C → add hot sand to the sand mixer → evenly add resin and dibutyl fat (completed in 40 seconds) → start filming at the same time → spray curing agent after 75 seconds → add stearin after 35 seconds Calcium acid → air cooling for 60 seconds, sand production → crushing, sieving → proceed to the next cycle.

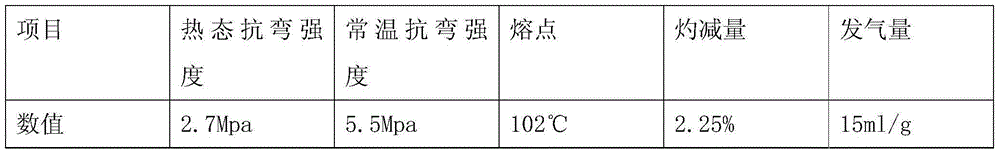

[0032]

Embodiment 2

[0034] Thermal reclaimed sand is 50 / 100 mesh, Baozhu sand is 50 / 100 mesh, Baozhu sand accounts for 100% of the original sand weight, thermal method regenerated sand accounts for 0% of the original sand weight, the adhesive is 3% of the original sand weight, and the curing agent is 60% of the weight of the adhesive, the coupling agent is 0.8% of the weight of the adhesive, the lubricant is 60% of the weight of the adhesive, and the plasticizer is 8% of the weight of the adhesive.

[0035] Start the machine → preheat the raw sand to 148°C → add hot sand to the sand mixer → evenly add resin, dibutyl fat and silane (completed in 40 seconds) → start coating at the same time → spray curing agent after 85 seconds → add after 35 seconds Calcium stearate → air cooling for 60 seconds, sand production → crushing, sieving → proceed to the next cycle.

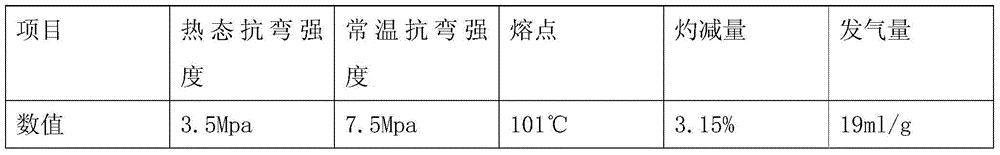

[0036]

Embodiment 3

[0038] Thermal reclaimed sand is 40 / 70 mesh, Baozhu sand is 50 / 100 mesh, Baozhu sand accounts for 50% of the original sand weight, thermal method regenerated sand accounts for 50% of the original sand weight, the adhesive is 2.5% of the original sand weight, and the curing agent is 50% of the weight of the adhesive, the coupling agent is 0.55% of the weight of the adhesive, the lubricant is 50% of the weight of the adhesive, and the plasticizer is 6.5% of the weight of the adhesive.

[0039] Start the machine → preheat the raw sand to 143°C → add hot sand to the sand mixer → evenly add resin, dibutyl fat and silane (completed in 40 seconds) → start coating at the same time → spray curing agent after 80 seconds → add after 30 seconds Calcium stearate → air cooling for 60 seconds, sand production → crushing, sieving → proceed to the next cycle.

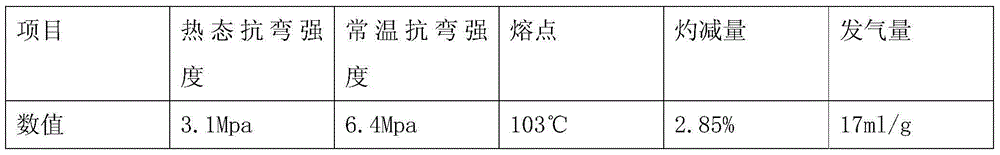

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com