Austenitic stainless steel with excellent polishing performance and manufacturing method thereof

A technology of austenitic stainless steel and manufacturing method, applied in the field of austenitic stainless steel and its manufacturing, to achieve the effects of improving plasticity and cutting performance, improving polishing performance, and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

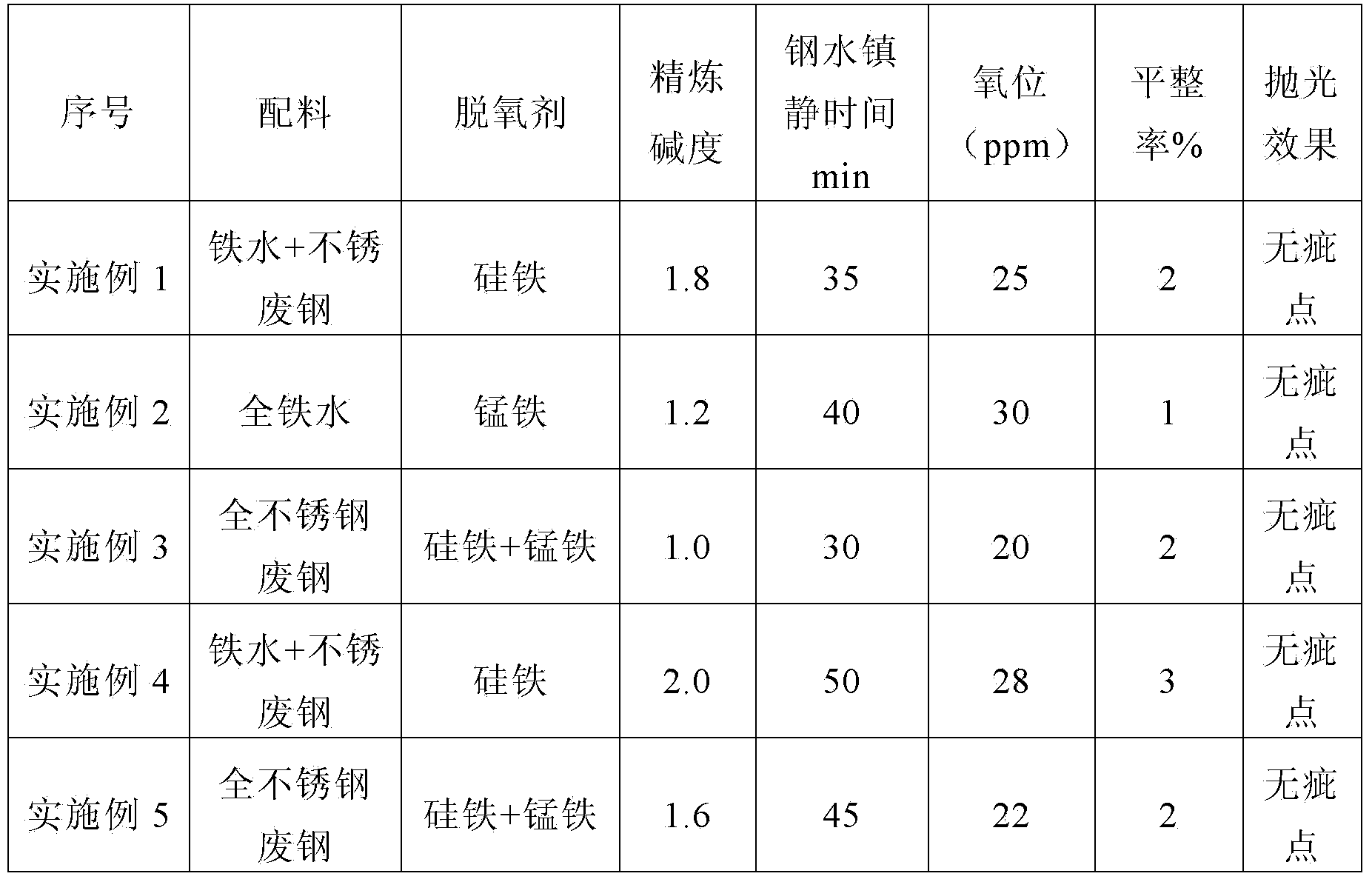

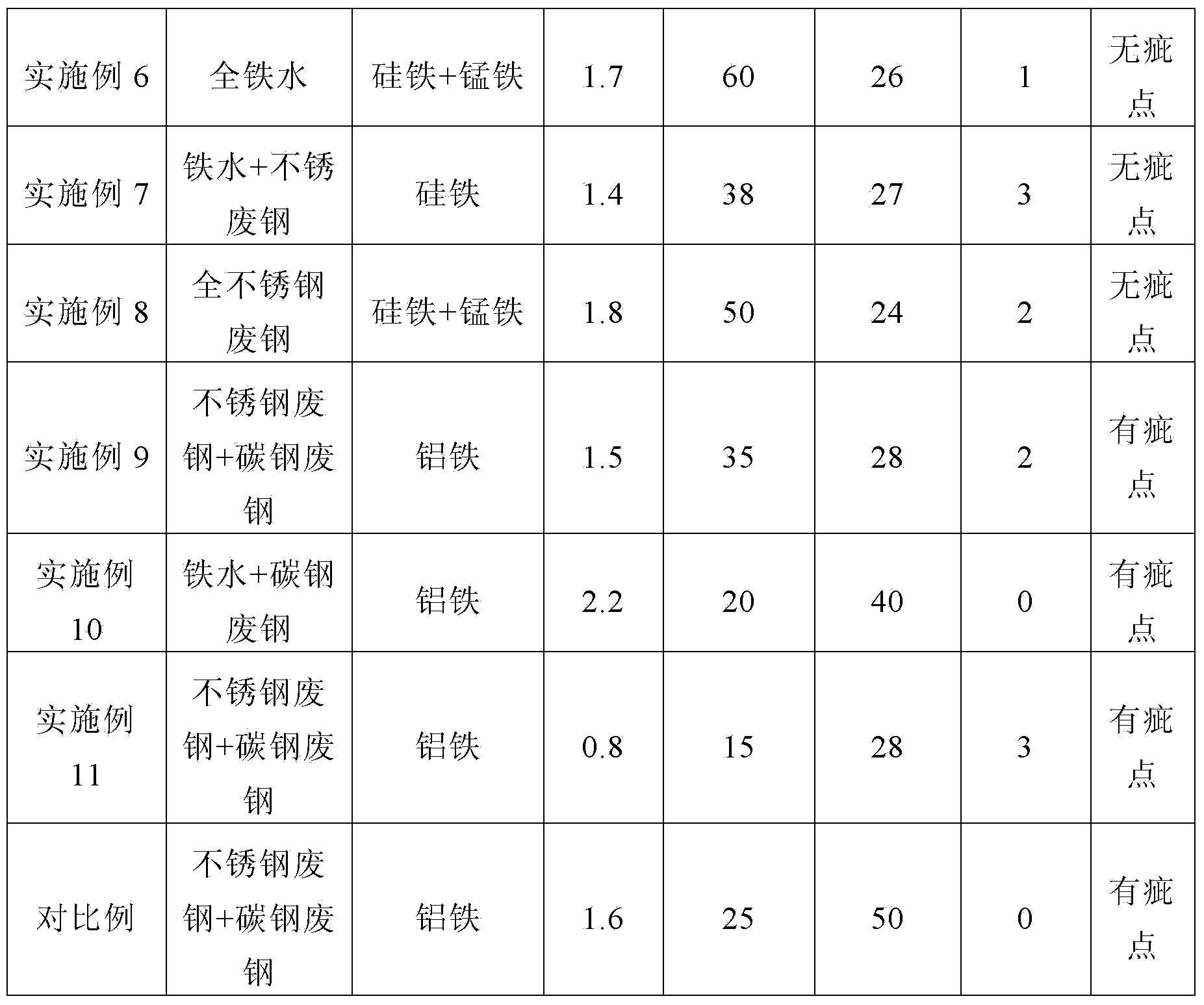

[0032] The present invention will be further described below by embodiment.

[0033] Table 1 is the chemical composition of the examples of the present invention, Table 2 is the process control points of the examples of the present invention, and the comparative example is conventional 304 stainless steel.

[0034] Using low-aluminum hot metal and stainless steel scrap as the main raw materials, it is smelted into conventional 304 stainless steel by electric furnace-AOD, in which the Cu content is controlled to 0.8%, and the deoxidizer in AOD is ferrosilicon; after entering the refining furnace, limestone is used to remake Slag, control the alkalinity at 1.8; in the later stage of refining, add S iron to adjust the S content of the molten steel to 0.003%, and blow argon gas to stir strongly; Protect the molten steel to prevent secondary oxidation, and control the oxygen level at 25ppm; use new rolls to roll the slab after heating, and do not remove phosphorus during the rollin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com